PTFE Bellows Seals: Sealing the Deal in Aggressive Conditions

PTFE Bellows Seals: Sealing the Deal in Aggressive Conditions

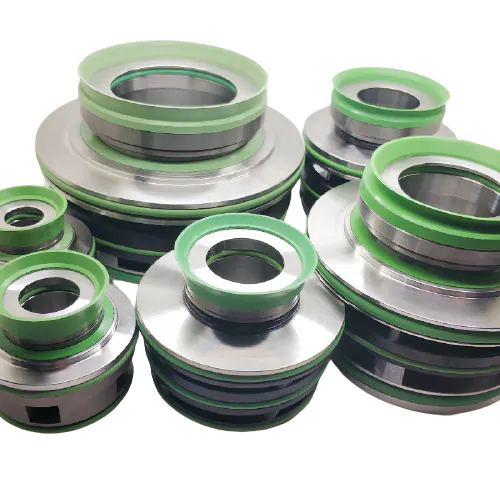

Introduction to PTFE Bellows Seals

PTFE Bellows Seals are essential components used in a variety of industries to ensure effective sealing even in the most aggressive conditions. In this article, we will delve into the world of PTFE (polytetrafluoroethylene) bellows seals, their importance, and how they help seal the deal in challenging environments.

Understanding PTFE and Its Properties

PTFE is a high-performance fluoropolymer known for its exceptional chemical resistance, low friction coefficient, and wide temperature range. It possesses excellent mechanical properties, electrical insulation capabilities, and is chemically inert. These characteristics make PTFE an ideal material for bellows seals, which find applications in various industries, including chemical processing, pharmaceuticals, petrochemicals, and more.

How PTFE Bellows Seals Work

PTFE bellows seals are designed to provide a reliable seal between two components that have relative motion, such as rotating or reciprocating shafts. Their unique corrugated structure allows for axial, angular, and radial movement while maintaining a tight seal. The flexibility of the bellows compensates for any misalignment, vibrations, and thermal expansions, ensuring no leakage of the process fluid or ingress of contaminants.

Advantages of PTFE Bellows Seals

The utilization of PTFE bellows seals offers several advantages over traditional sealing methods. Firstly, their outstanding chemical resistance allows them to handle aggressive media, including corrosive chemicals and solvents. Secondly, the self-lubricating nature of PTFE reduces friction and wear, leading to improved sealing and extended operational life. Additionally, PTFE bellows seals require minimal maintenance, resulting in reduced downtime and increased productivity.

Application Areas and Case Studies

PTFE bellows seals find extensive use in various industries due to their reliability and performance. Let's explore some application areas where these seals play a crucial role:

1. Chemical Processing: PTFE bellows seals are employed in pumps, mixers, agitators, and reactors, ensuring leak-free operation and preventing contamination of highly corrosive chemicals.

2. Pharmaceutical Industry: PTFE bellows seals maintain sterility in pharmaceutical production equipment, minimizing the risk of cross-contamination and ensuring product integrity.

3. Petrochemical Plants: PTFE bellows seals are essential for sealing pumps and compressors in petrochemical plants. They provide leak-free operation in demanding environments, such as high pressures and temperatures, and with aggressive media.

4. Food and Beverage Industry: PTFE bellows seals are widely used in food processing equipment, meeting stringent hygiene standards while providing effective sealing, thus preventing any contamination.

5. Oil and Gas Sector: PTFE bellows seals play a vital role in the oil and gas industry. They seal centrifugal pumps, providing reliable operation in harsh conditions, including high temperatures, corrosive fluids, and abrasive particles.

Case Study 1: A chemical processing plant was experiencing frequent leakages in their pumps due to the corrosive nature of the processed chemicals. By implementing PTFE bellows seals, the plant achieved a significant reduction in downtime and maintenance costs, ensuring uninterrupted production.

Case Study 2: In the pharmaceutical industry, a manufacturer was facing challenges in maintaining aseptic conditions during the production of vaccines. By utilizing PTFE bellows seals, the risk of contamination was eliminated, resulting in improved product quality and increased customer trust.

Conclusion:

PTFE Bellows Seals are instrumental in sealing the deal in aggressive conditions. Their ability to withstand harsh environments, resist chemicals, and provide effective sealing makes them indispensable in numerous industries. Whether it's chemical processing, pharmaceuticals, petrochemicals, or food and beverage, PTFE bellows seals ensure uninterrupted operation, reliability, and process efficiency. Embracing this advanced sealing technology leads to enhanced productivity, reduced operating costs, and improved safety in aggressive conditions.