O-Ring Mechanical Seals: The Versatile Sealing Solution for Fluid Systems

O-Ring Mechanical Seals: The Versatile Sealing Solution for Fluid Systems

Introduction

Fluid systems are essential to countless industries, from manufacturing to oil and gas. These systems rely on efficient and reliable sealing solutions to prevent leakage and ensure operational integrity. One such solution that has gained immense popularity is the O-ring mechanical seal. In this article, we will explore the versatility of O-ring mechanical seals and how they revolutionize fluid systems. From their design and materials to their applications and benefits, O-ring mechanical seals are truly a game-changer for industries worldwide.

Understanding O-Ring Mechanical Seals

1. A Brief Overview of Mechanical Seals

2. The Role of O-Rings in Mechanical Seals

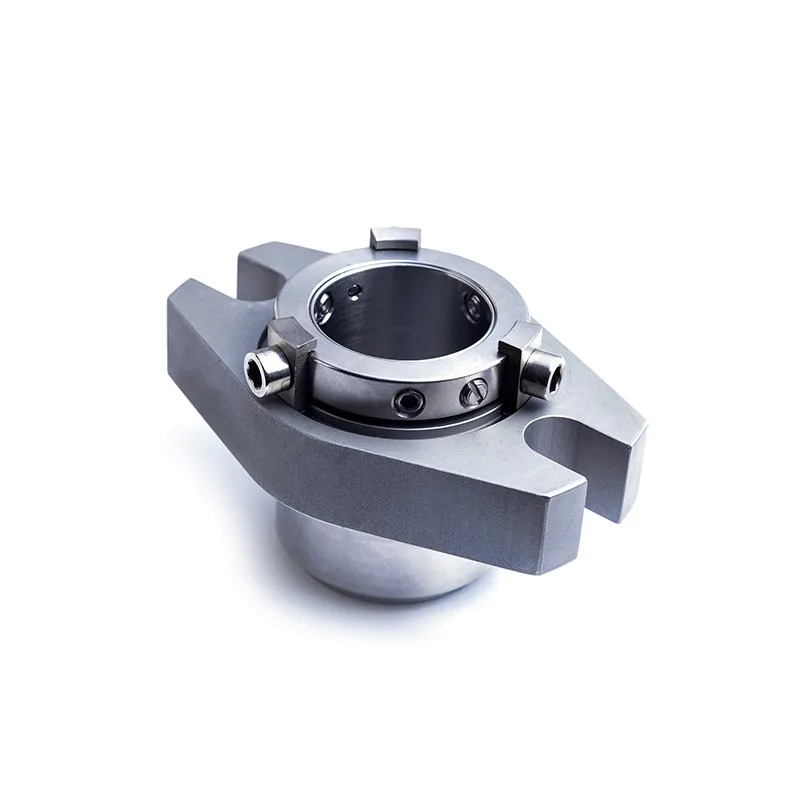

Before diving into the versatility of O-ring mechanical seals, it's important to understand what mechanical seals are and the specific role O-rings play in their functionality. Mechanical seals are devices used to prevent leakage in fluid systems by creating a barrier between two mating surfaces, often a rotating shaft and a stationary housing. O-rings, on the other hand, are circular rubber or elastomeric rings that are precisely sized to fit within a mechanical seal. They serve as the primary sealing component, ensuring a tight and leak-free connection between the mating surfaces.

Versatile Applications of O-Ring Mechanical Seals

1. Industrial Applications

2. Oil and Gas Industry

3. Food and Beverage Industry

O-ring mechanical seals find applications across various industries due to their versatility and reliability. In industrial settings, these seals are commonly used in pumps, compressors, mixers, and agitators, among others. Their ability to handle a wide range of fluids, pressures, and temperatures makes them a popular choice in industrial manufacturing.

Furthermore, the oil and gas industry heavily relies on O-ring mechanical seals to maintain the integrity of pipelines, refineries, and offshore platforms. Operating in extreme conditions, such as high pressures and temperatures, these seals ensure that hazardous fluids do not leak into the environment.

In the food and beverage industry, O-ring mechanical seals play a critical role in maintaining hygiene and preventing contamination. From dairy processing to beer production, these seals provide a secure and leak-free connection, ensuring product quality and safety.

Advantages of O-Ring Mechanical Seals

1. Enhanced Seal Performance

2. Wide Range of Compatible Fluids

3. Easy Installation and Maintenance

4. Cost-Effective Solution

5. Improved Equipment Reliability

The versatility of O-ring mechanical seals stems from their numerous advantages. Firstly, their enhanced seal performance minimizes leakage and extends equipment lifespan. As O-ring seals are designed to effectively handle dynamic and static sealing applications, they provide superior sealing capabilities even under demanding conditions.

Moreover, O-ring mechanical seals are compatible with a wide range of fluids, including water, oils, chemicals, and gases. This versatility allows industries to use a single sealing solution for multiple applications, reducing inventory costs and simplifying procurement processes.

Another significant advantage of O-ring mechanical seals is their ease of installation and maintenance. Unlike other sealing methods that may require specialized tools or expertise, O-ring seals can be easily installed and replaced without extensive downtime.

Furthermore, O-ring mechanical seals offer a cost-effective sealing solution. Their durability and resistance to wear, tear, and corrosion minimize replacement and repair costs, ultimately leading to cost savings for industries.

Lastly, by preventing leakage and ensuring system integrity, O-ring mechanical seals improve equipment reliability. Reduced downtime and maintenance requirements lead to enhanced productivity and overall operational efficiency.

Material Considerations for O-Ring Mechanical Seals

1. Common Materials Used in O-Rings

2. Selecting the Right Material for Specific Applications

O-ring mechanical seals are manufactured using a variety of materials, each possessing unique properties to suit specific applications. Common materials used in O-rings include nitrile rubber (NBR), fluorocarbon rubber (FKM), silicone rubber (VMQ), ethylene propylene rubber (EPDM), and polytetrafluoroethylene (PTFE).

When selecting the right material for a particular application, factors such as temperature, pressure, fluid compatibility, and chemical resistance must be considered. For instance, FKM O-rings are highly resistant to chemicals and can withstand extreme temperatures, making them suitable for the oil and gas industry. On the other hand, EPDM O-rings are commonly used in food and beverage applications where they must comply with strict hygiene regulations.

Conclusion

O-ring mechanical seals have established themselves as a versatile sealing solution for fluid systems across a wide range of industries. Their ability to provide superior seal performance, handle various fluids and temperatures, and offer easy installation and maintenance make them the go-to choice for countless applications. As industries continue to evolve, O-ring mechanical seals will remain crucial in ensuring the efficiency, reliability, and safety of fluid systems worldwide.