Maximizing Seal Life Expectancy in Aggressive Fluid Environments with Metal Bellow Mechanical Seals

Introduction

Metal bellow mechanical seals play a crucial role in ensuring the efficiency and integrity of machinery operating in aggressive fluid environments. These environments often subject equipment to extreme conditions such as high pressure, temperature, corrosive chemicals, and abrasive substances. In such challenging scenarios, it becomes imperative to maximize the seal life expectancy to avoid costly downtime, maintenance, and replacements. This article delves into the strategies and technologies that can effectively enhance the durability and performance of metal bellow mechanical seals, enabling them to thrive in aggressive fluid environments.

The Importance of Metal Bellow Mechanical Seals in Aggressive Fluid Environments

Aggressive fluid environments pose significant challenges to the efficient operation of machinery. The presence of corrosive substances, high pressures, and extreme temperatures can result in leakages, equipment failure, and compromised safety. Metal bellow mechanical seals provide a reliable solution to these challenges by ensuring proper sealing between rotating and stationary parts, thereby preventing fluid leakage, contamination, and loss of efficiency. These seals are specifically designed to withstand harsh operating conditions, offering high resistance to wear, corrosion, and extreme temperatures.

Understanding Metal Bellow Mechanical Seals

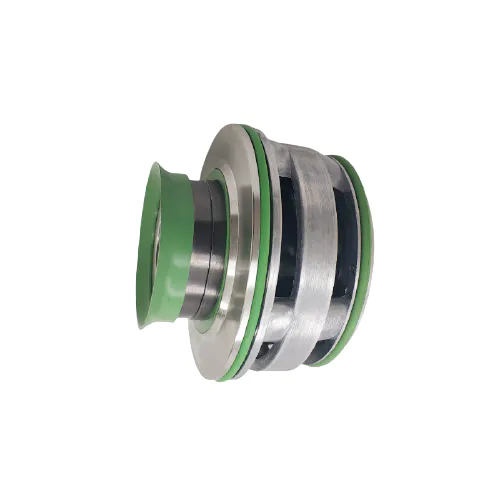

Metal bellow mechanical seals consist of two primary components: a stationary part, also known as the seal head, and a rotating part referred to as the mating ring. These components work together to provide a continuous and effective seal even in aggressive fluid environments. The seal head is mounted stationary around the shaft, while the mating ring rotates with the equipment. The metal bellow, a key element of the seal, allows axial, radial, and angular movements to accommodate these rotations while maintaining a tight seal.

Enhancing Durability in Aggressive Fluid Environments

To maximize the life expectancy of metal bellow mechanical seals in aggressive fluid environments, several strategies can be employed. By considering the following factors, the durability and performance of these seals can be significantly improved:

Material Selection

Selecting the appropriate materials for metal bellow mechanical seals is crucial to ensure resistance to corrosion, wear, and extreme temperatures. Common materials used include stainless steel, Hastelloy, and titanium. Factors such as fluid compatibility, temperature range, and mechanical properties must be taken into account while choosing materials to optimize the performance and lifespan of the seal.

Surface Coatings and Treatments

Applying surface coatings and treatments to metal bellow mechanical seals can provide enhanced resistance to corrosion, erosion, and chemical attack. Coating technologies such as physical vapor deposition (PVD) and chemical vapor deposition (CVD) offer improved surface hardness, low friction, and enhanced durability. Additionally, treatments like passivation and nitriding further enhance the seals' resistance to aggressive fluids, extending their life expectancy.

Design Considerations

The design of metal bellow mechanical seals plays a vital role in their performance and longevity. Considerations such as seal face geometry, spring loading, and seal head configuration are crucial to ensure optimal sealing, reduce wear, and prevent fluid leakage. Proper alignment, balanced loading, and sufficient cooling mechanisms must also be incorporated into the design to enhance the seal's durability.

Fluid Control and Filtration

Controlling the fluid environment and implementing effective filtration methods can significantly enhance the life expectancy of metal bellow mechanical seals. Monitoring and maintaining the fluid's pH level, temperature, and cleanliness can minimize the occurrence of corrosive reactions and abrasive particles that accelerate seal wear. Well-designed filtration systems help remove contaminants and extend the operational life of the seals.

Advancements in Seal Technology

Continual advancements in seal technology have revolutionized the performance and durability of metal bellow mechanical seals. Manufacturers are now incorporating innovative features such as self-aligning capabilities, adaptive sealing faces, and advanced sealing materials to enhance the seals' resistance to aggressive fluids. These advancements ensure improved sealing performance, reduced friction, and extended lifespan, ultimately resulting in enhanced equipment efficiency and reduced maintenance costs.

Conclusion

In aggressive fluid environments, the durability and performance of metal bellow mechanical seals are crucial for the smooth operation of equipment. By carefully considering material selection, surface coatings, design considerations, fluid control, and advancements in seal technology, the life expectancy of these seals can be significantly maximized. Implementing these strategies not only ensures long-term operational reliability but also reduces maintenance costs, minimizes downtime, and enhances the overall efficiency of machinery functioning in aggressive fluid environments. With continuous research and development, manufacturers can continue to enhance the performance of metal bellow mechanical seals and meet the evolving demands of increasingly aggressive fluid environments.