Improving Pump Efficiency with Precision Clearance Seals

Improving Pump Efficiency with Precision Clearance Seals

Introduction

Pumps play a critical role in various industrial processes, ensuring the smooth flow of liquids and gases. However, inefficient pump performance can lead to increased energy consumption, reduced reliability, and unnecessary maintenance costs. One of the key factors influencing pump efficiency is the presence of clearance gaps between the rotating shaft and stationary parts. In this article, we will explore how precision clearance seals can significantly enhance pump efficiency, resulting in improved overall performance and reduced operational expenses.

Understanding Pump Clearance Gaps

1. The Significance of Pump Clearance Gaps

Pump clearance gaps are crucial features that allow for rotation and prevent the physical contact between the shaft and the surrounding stationary components. While these gaps are necessary, they can also introduce various challenges, adversely affecting pump performance. Some of the common issues associated with clearance gaps include leakage, reduced efficiency, and heightened energy consumption. Therefore, it is essential to address these challenges effectively to ensure optimal pump operation.

2. Impact of Clearance Gaps on Pump Efficiency

Clearance gaps in pumps give rise to internal leakage, known as recirculation, which hampers the pumping process. This recirculation reduces the pump's capacity to deliver fluids or gases as it diverts some of the flow back to the suction side, diminishing the overall efficiency. Additionally, increased leakage can lead to higher energy consumption due to the need for excessive power to compensate for the lost flow. Precision clearance seals offer a reliable solution to mitigate these issues, thereby improving pump efficiency.

Improving Pump Efficiency with Precision Clearance Seals

1. How Precision Clearance Seals Work

Precision clearance seals are designed to minimize the leakage occurring through the clearance gaps in pumps. These seals are delicately engineered to fit precisely and effectively create a barrier between the rotating shaft and stationary components. By reducing the internal recirculation and leakage, these seals enhance the pump's ability to deliver the desired flow, resulting in improved efficiency.

2. Types of Precision Clearance Seals

a. Fluid Film Seals

Fluid film seals are commonly used to reduce leakage by forming a thin film of fluid between the rotating shaft and the stationary parts. This film, typically made of lubricating oil or specially formulated fluid, creates a hydrodynamic barrier, thus restricting the recirculation. By using fluid film seals, engineers can effectively reduce leakage and boost pump efficiency.

b. Labyrinth Seals

Labyrinth seals consist of a series of tightly spaced interlocking teeth that form a tortuous path, preventing fluid or gas from escaping through the clearance gaps. The labyrinth design increases the path length and turbulence, reducing leakage and recirculation. These seals are widely employed in pumps where high-pressure differentials are involved.

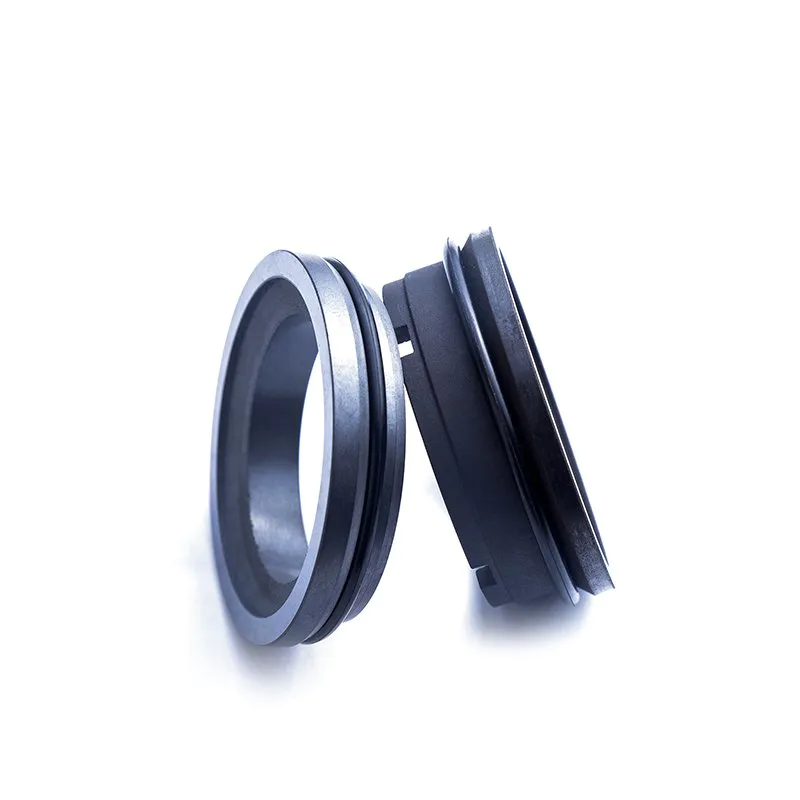

c. Mechanical Face Seals

Mechanical face seals, also known as mechanical seals, comprise two flat surfaces pressed together with a secondary seal to ensure fluid-tightness. These seals are effective in preventing leakage by maintaining a close clearance between the rotating and stationary components. Mechanical face seals are often used in challenging pump applications, including corrosive or abrasive fluids.

3. Advantages of Precision Clearance Seals

a. Enhanced Pump Efficiency

The primary objective of incorporating precision clearance seals is to improve pump efficiency. By significantly reducing internal recirculation and leakage, these seals allow the pump to operate closer to its design parameters, resulting in improved efficiency and reduced energy consumption.

b. Extended Pump Life

Precision clearance seals play a crucial role in protecting the rotating shaft and stationary parts of the pump. By minimizing contact and friction between these components, the seals contribute to increased equipment longevity. This extended pump life reduces maintenance costs and enhances overall reliability.

c. Reduced Downtime and Maintenance Expenses

When pumps experience excessive leakage and a diminished performance, unscheduled maintenance becomes necessary. By using precision clearance seals, the risk of leaks and the need for frequent repairs or replacements is reduced. This leads to minimal downtime and lower maintenance expenses, ultimately benefiting the overall operational efficiency.

d. Environmental Impact

Efficient pump operation significantly reduces energy consumption, resulting in a reduced carbon footprint. Precision clearance seals indirectly contribute to a more sustainable environment by optimizing pump performance and minimizing wasted resources.

Conclusion

In conclusion, precision clearance seals are integral to improving pump efficiency and reducing operational costs. By mitigating internal leakage and enhancing pump performance, engineers can achieve optimal flow rates, lower energy consumption, and an extended pump lifespan. Investing in precision clearance seals allows industries to efficiently meet their demanding pumping requirements while promoting sustainability and minimizing environmental impact.