Hygienic Design Considerations for Fristam Mechanical Seals in the Dairy Industry

Hygienic Design Considerations for Fristam Mechanical Seals in the Dairy Industry

Introduction

Mechanical seals play a crucial role in maintaining the integrity and hygienic conditions within the dairy industry. With the increasing demand for high-quality dairy products, it is essential to ensure that the equipment used is designed with hygiene in mind. Fristam, a leading manufacturer of mechanical seals, understands these requirements and offers innovative solutions that meet the stringent standards of the dairy industry. In this article, we will explore the key considerations for hygienic design when using Fristam mechanical seals in dairy processing.

Seal Material Selection

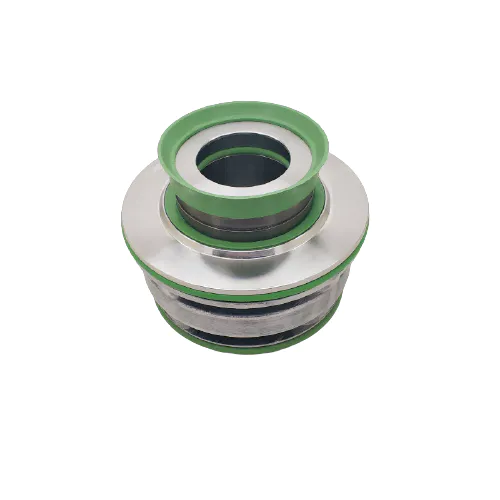

One of the critical factors to consider when designing mechanical seals for the dairy industry is the choice of seal materials. Fristam offers a range of FDA-approved materials, such as stainless steel, carbon, and PTFE, that are resistant to corrosion and bacterial growth. These materials ensure that the mechanical seal maintains its integrity, even under the harsh conditions of the dairy processing environment. The selection of appropriate materials is crucial to prevent product contamination and comply with food safety regulations.

Ease of Cleaning and CIP

Maintaining cleanliness and preventing bacterial growth are of utmost importance in the dairy industry. Therefore, mechanical seals should be designed to be easily cleaned and sanitized. Fristam mechanical seals feature a sanitary design, with smooth surfaces and minimal crevices that can harbor bacteria. Additionally, they can be easily disassembled without the need for special tools, enabling efficient cleaning and inspection during regular maintenance procedures.

Resistant to Thermal Cycling

Dairy processing involves frequent temperature changes, including pasteurization and cooling stages. Mechanical seals used in the dairy industry must be capable of withstanding these thermal cycling conditions without compromising their performance. Fristam mechanical seals are designed to withstand extreme temperature variations, ensuring reliable operation and preventing leakage or product contamination. Their robust design and high-quality materials make them an ideal choice for applications that involve repeated exposure to extreme temperatures.

Seal Flush Systems

In certain dairy processes, it may be necessary to use seal flush systems to ensure product integrity and prevent contamination. Fristam offers innovative seal flush systems that effectively handle the challenges posed by dairy products. These systems provide a continuous flow of clean fluid or CIP solution to the seal faces, preventing any product residue from entering the seal cavity. By maintaining a positive pressure, the seal flush system helps avoid product leakage or contamination, enhancing the overall hygiene and safety of the dairy processing equipment.

Hygienic Design Standards

The dairy industry is subject to numerous regulations and standards to maintain the highest standards of hygiene and food safety. Fristam understands the importance of complying with these standards and ensures that their mechanical seals meet the required industry certifications. By adhering to hygienic design standards such as 3A and EHEDG, Fristam mechanical seals offer the dairy industry peace of mind, knowing that their equipment meets the necessary regulations.

Conclusion

Maintaining hygienic conditions is paramount in the dairy industry to ensure the production of safe and high-quality products. Fristam mechanical seals provide a reliable solution, designed with hygiene in mind. The selection of appropriate seal materials, ease of cleaning and sanitization, resistance to thermal cycling, seal flush systems, and compliance with hygienic design standards make Fristam mechanical seals a preferred choice for dairy processors worldwide. By incorporating these considerations into the design of mechanical seals, Fristam continues to contribute to the advancement of hygienic practices in the dairy industry, setting new standards for safety and quality.