How Tungsten Carbide Seal Rings Improve Equipment Reliability in Oil and Gas Operations

Title: How Tungsten Carbide Seal Rings Improve Equipment Reliability in Oil and Gas Operations

Introduction:

Tungsten carbide seal rings have emerged as a game-changing solution in the oil and gas industry, revolutionizing equipment reliability, and enhancing overall operational efficiency. This article explores the multifaceted benefits of using tungsten carbide seal rings, including increased durability, improved sealing performance, reduced maintenance costs, enhanced operational safety, and contribution to a sustainable future.

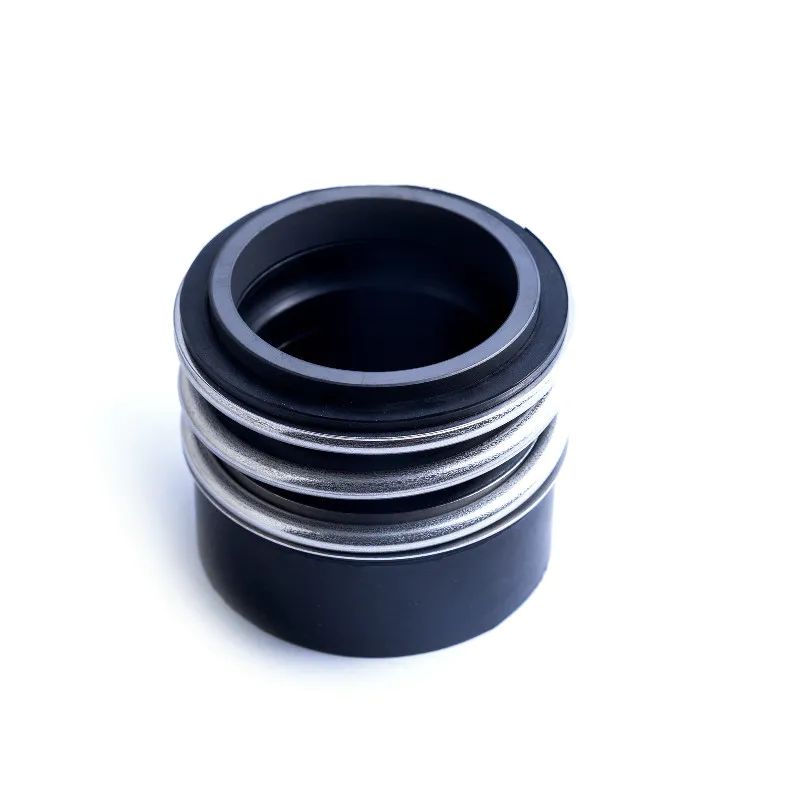

Enhanced Durability for Longer-lasting Equipment

Tungsten carbide seal rings possess exceptional hardness and wear resistance, making them a superior choice for demanding oil and gas operations. These seal rings exhibit remarkable resistance to abrasion, erosion, and chemical corrosion, ensuring prolonged equipment longevity. With increased durability, equipment downtime and replacement costs are significantly reduced, augmenting operational efficiency.

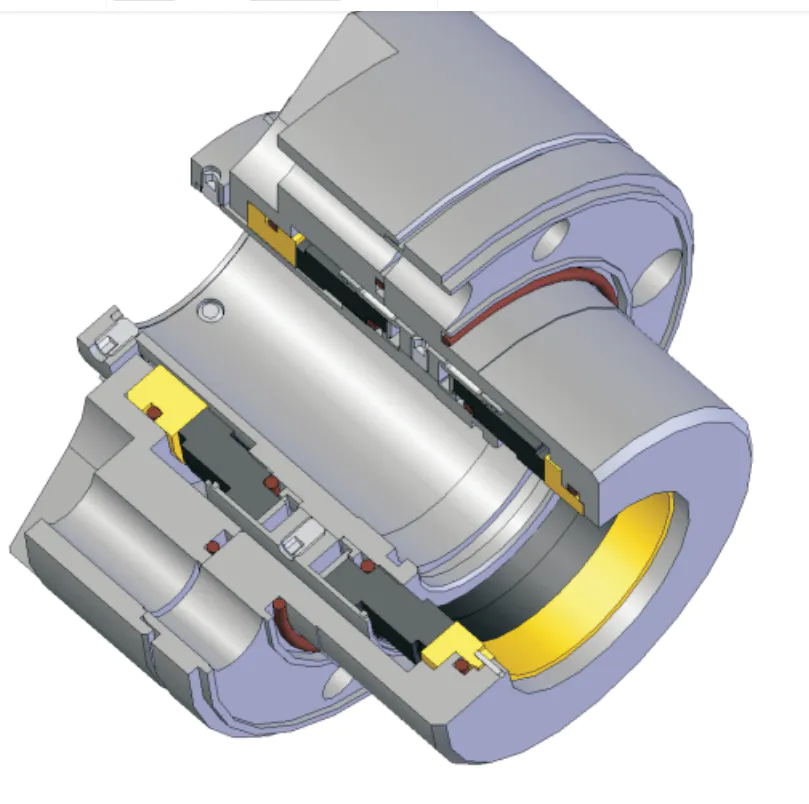

Improved Sealing Performance Ensuring Leakage-Free Operations

The precision and tight sealing capabilities of tungsten carbide seal rings are unmatched. These rings effectively prevent fluid leakage even under high pressures, extreme temperatures, and aggressive chemical environments. By ensuring leakage-free operations, these seal rings enhance the overall safety of oil and gas equipment, thus minimizing potential hazards and ensuring uninterrupted productivity.

Reduced Maintenance Costs with Minimal Wear and Tear

The exceptional wear resistance of tungsten carbide seal rings significantly reduces the need for frequent maintenance interventions. Unlike conventional seals that wear out quickly, tungsten carbide seal rings exhibit minimal wear and tear, resulting in decreased maintenance costs and extended equipment lifespan. The reduced maintenance requirements translate into higher cost savings for oil and gas operators, improving their bottom line.

Enhancing Operational Safety in Challenging Environments

Oil and gas operations often face challenging environments characterized by high pressures, extreme temperatures, and corrosive chemicals. Tungsten carbide seal rings offer exceptional resistance to such harsh conditions, ensuring reliable and safe equipment performance. By minimizing the risk of equipment failure and leaks, these seal rings contribute to a safer working environment for personnel and protect valuable assets.

Tungsten Carbide: A Sustainable Solution for the Future

As the global focus on sustainability intensifies, tungsten carbide seal rings emerge as an environmentally friendly solution for the oil and gas industry. These rings are manufactured using tungsten, which is abundantly available and economically viable. Furthermore, their exceptional durability reduces the need for frequent replacements, reducing waste generation and minimizing the industry's environmental footprint. By embracing tungsten carbide seal rings, oil and gas operators contribute to a greener, more sustainable future.

Conclusion:

Tungsten carbide seal rings are a vital component in enhancing equipment reliability in oil and gas operations. Their exceptional durability, improved sealing performance, reduced maintenance costs, enhanced safety, and sustainability benefits make them indispensable in this demanding industry. By incorporating tungsten carbide seal rings into their equipment, oil and gas operators can optimize operations, improve productivity, and ensure a more sustainable future.