How Pillar Mechanical Seals Improve Reliability in Chemical Processing

Understanding the Significance of Mechanical Seals in Chemical Processing

In the world of chemical processing, ensuring reliability and safety is of utmost importance. Numerous pieces of equipment and components play a crucial role in achieving these objectives, and one such vital element is the mechanical seal. Mechanical seals are essential to prevent leakage and maintain the integrity of various machinery. This article delves into the significance of pillar mechanical seals and highlights their contributions in enhancing reliability within the chemical processing industry.

The Basics of Mechanical Seals and Their Function in Chemical Processing

Mechanical seals are devices used to seal the gap between two surfaces in rotating equipment, such as pumps and mixers. By creating a seal between the rotating shaft and the stationary housing, mechanical seals prevent leaks, contamination, and potential hazards in chemical processing plants. The primary function of these seals is to maintain the integrity of the system through effective sealing, which is crucial for consistent operation and avoiding unplanned shutdowns.

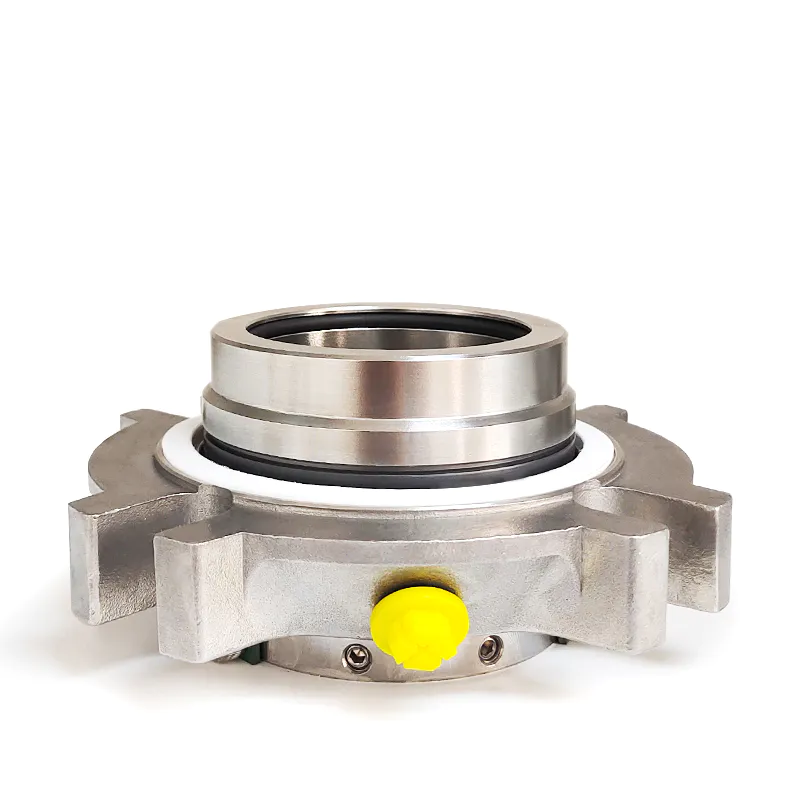

Introducing Pillar Mechanical Seals and Their Unique Advantages

Pillar mechanical seals are a specific type of mechanical seal widely used in chemical processing plants. These seals offer several benefits over alternative sealing methods, making them an excellent choice for maintaining reliability. A distinct advantage of pillar mechanical seals is their ability to withstand high pressures and temperatures commonly found in chemical processing applications. Their robust construction, coupled with advanced materials, allows them to endure harsh conditions and prevent leaks effectively.

Enhancing Reliability through Efficient Containment and Leak Prevention

One of the primary concerns in chemical processing plants is the containment of hazardous substances. Mechanical seals, and specifically pillar mechanical seals, play a vital role in preventing leaks and ensuring the protection of both the equipment and personnel. These seals are meticulously designed to provide a tight seal, minimize friction, and eliminate the risk of leakage, contributing significantly to the overall reliability of chemical processing systems.

The Role of Pillar Mechanical Seals in Reducing Downtime and Maintenance Costs

Unplanned equipment shutdowns in chemical processing plants can be costly and disruptive. Mechanical seals, including pillar seals, offer a crucial solution to mitigate downtime and reduce maintenance costs. By effectively sealing rotating equipment, these seals minimize the risk of leaks, which can result in equipment failure, lost production, and costly repairs. Pillar mechanical seals, with their sturdy design and longevity, help prevent frequent breakdowns, allowing for uninterrupted operation and reducing overall maintenance expenses.

In conclusion, mechanical seals, particularly pillar mechanical seals, are indispensable components in the chemical processing industry. They play a significant role in improving reliability by providing efficient containment, preventing leaks, and reducing maintenance costs. With their ability to withstand harsh operating conditions and their contribution to continuous operation, pillar mechanical seals ensure the safety, productivity, and profitability of chemical processing plants.