Flygt Pump Seal Failure: Causes, Prevention, and Solutions

Flygt Pump Seal Failure: Causes, Prevention, and Solutions

Understanding the Importance of Pump Seals

Common Causes of Flygt Pump Seal Failure

Preventive Measures to Minimize Seal Failure

Troubleshooting and Solutions for Flygt Pump Seal Failure

Considering Alternative Sealing Solutions for Flygt Pumps

Understanding the Importance of Pump Seals

Pump seals play a critical role in maintaining the efficiency and functionality of Flygt pumps. Essentially, pump seals are mechanical devices that prevent leakage of fluid from the pump housing. They ensure that fluids are contained within the system, preventing environmental contamination and preserving the pump's performance. With a failed seal, a pump can quickly lose efficiency and lead to costly repairs or replacements. Understanding the causes, prevention, and solutions to Flygt pump seal failure is crucial for any facility or industry relying on these pumps.

Common Causes of Flygt Pump Seal Failure

Flygt pump seal failure can occur due to various reasons. One common cause is improper installation, where technicians may not have followed the manufacturer's guidelines correctly. This can result in misalignment or inadequate tension, compromising the seal's performance. Another cause is the presence of abrasive or corrosive fluids that wear down the seal material over time. Excessive heat, pressure, or vibration can also contribute to seal failure by degrading the seal's effectiveness or causing premature wear.

Preventive Measures to Minimize Seal Failure

To minimize the risk of Flygt pump seal failure, implementing preventive measures is essential. Regular maintenance and inspections are critical to identifying early signs of wear or misalignment. Ensuring that the correct seal material is selected based on the fluid being pumped is also crucial. Exposing seals to abrasive or corrosive fluids can significantly reduce their lifespan, so utilizing appropriate seals for specific applications is necessary. Proper installation techniques, including following the manufacturer's guidelines and using appropriate seal lubrication, can significantly enhance the likelihood of successful sealing.

Proper training for technicians responsible for installing and maintaining Flygt pumps is vital. Monitoring parameters such as temperature, pressure, and vibration can help detect potential issues before they escalate into seal failure. Implementing preventive measures, combined with regular maintenance and inspections, can significantly extend the lifespan of pump seals.

Troubleshooting and Solutions for Flygt Pump Seal Failure

When Flygt pump seals fail, it is essential to troubleshoot and rectify the issue promptly. One common indication of seal failure is a noticeable increase in fluid leakage around the pump housing. Upon identifying seal failure, it is crucial to address the root cause rather than simply replacing the failed seal. This approach aims to prevent recurring failures and minimize downtime.

First, check for any misalignment or insufficient tension in the seal. If detected, verify that the seal is correctly installed according to the manufacturer's guidelines. Adjustments may be necessary to realign the seal and provide the appropriate tension. If the seal material is degrading due to abrasive or corrosive fluids, consider replacing it with a more resistant material suitable for the application.

Regularly monitoring pump parameters and comparing them to recommended guidelines can help detect potential issues early on. Addressing any indications of excessive heat, pressure, or vibration promptly can prevent further damage to the seal and the pump itself.

Considering Alternative Sealing Solutions for Flygt Pumps

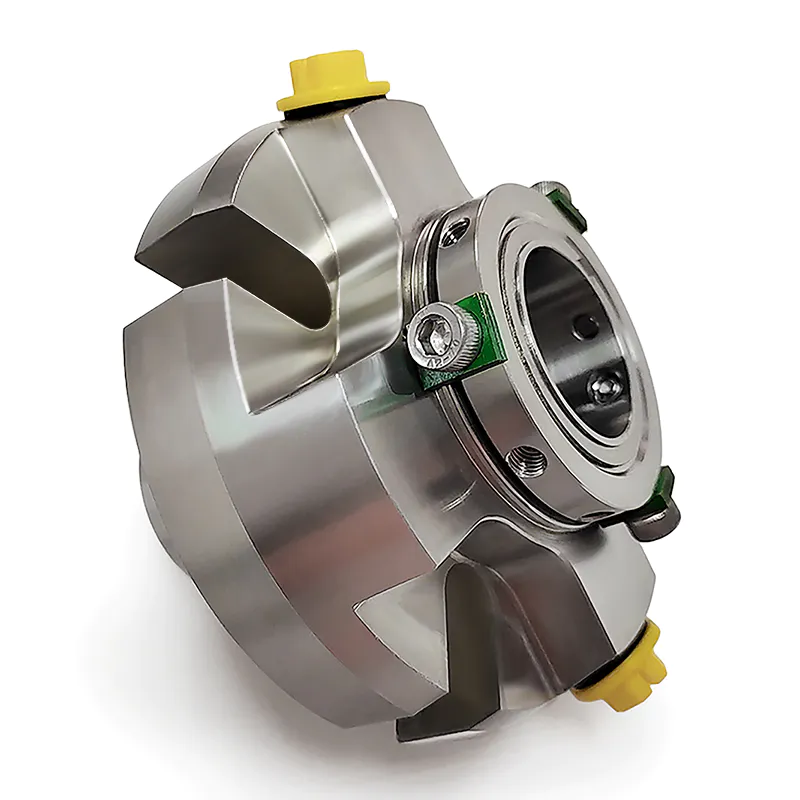

While Flygt pumps are reliable and widely used, alternative sealing solutions may offer benefits in certain applications. For example, mechanical seals are commonly used in pump systems as they provide superior sealing capabilities and can withstand harsh conditions. Additionally, cartridge seals, which are pre-assembled and ready for installation, can enhance the speed and ease of seal replacements when compared to traditional seals.

When considering alternative sealing solutions, carefully evaluate the specific requirements of your application. Factors such as fluid type, operating conditions, maintenance requirements, and budget should be considered before making a final decision.

In conclusion, understanding the causes, prevention, and solutions to Flygt pump seal failure is crucial for maintaining the efficiency and longevity of these pumps. Proper installation, selecting appropriate seal materials, regular maintenance, and monitoring of pump parameters are essential preventive measures. Troubleshooting seal failures promptly and addressing potential issues at their root cause is vital to prevent recurring failures. Lastly, considering alternative sealing solutions can provide benefits in specific applications. By prioritizing the importance of pump seals, industries and facilities can ensure reliable and efficient operations with minimal downtime.