Flygt Mechanical Seals: Addressing Seal Leakage Challenges in Pumping Systems

You Deserve a Leak-Free Pumping System: Introducing Flygt Mechanical Seals

Picture this: your industrial pumping system is operating smoothly, efficiently moving fluids through pipelines day in and day out. Suddenly, you notice a small leak near the pump seal. Ignoring it may seem like a tempting option, but in reality, even the tiniest of leaks can lead to significant problems. Luckily, Flygt Mechanical Seals are here to address seal leakage challenges in pumping systems and ensure uninterrupted operation.

The Importance of Reliable Mechanical Seals

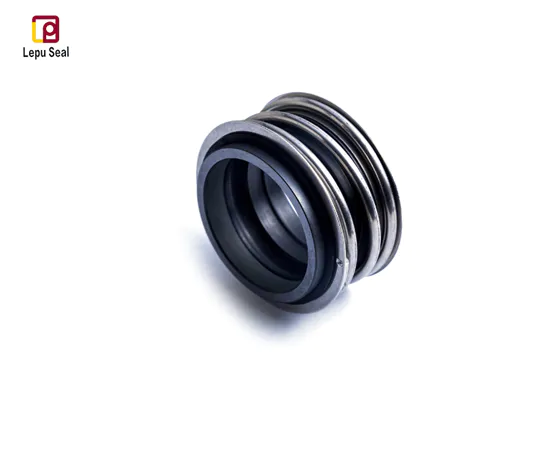

Mechanical seals are vital components in pumping systems, responsible for preventing fluid leakage and maintaining system integrity. They are engineered to withstand high pressures, extreme temperatures, and dynamic movements, all while keeping the fluid contained within the pump.

Leaking seals not only result in the loss of valuable fluids, but they also lead to increased energy consumption, decreased pump performance, premature equipment failure, and potential environmental hazards. Addressing seal leakage challenges promptly is crucial to avoiding costly repairs and maintaining operational efficiency.

Safeguarding Pumping Systems with Flygt Mechanical Seals

Flygt, a world-leading brand in fluid handling technology, offers an extensive range of mechanical seals designed to tackle seal leakage challenges head-on. With innovative engineering and cutting-edge materials, Flygt Mechanical Seals provide robust, reliable solutions for a wide variety of industrial applications.

To understand how Flygt Mechanical Seals effectively address seal leakage challenges, let's delve into the key features and benefits of their product line:

1. Enhanced Seal Face Materials

At the heart of every mechanical seal, you'll find the seal faces. Flygt integrates advanced seal face materials, such as silicon carbide, tungsten carbide, and carbon, providing exceptional wear resistance and chemical compatibility. These materials ensure extended seal life, reducing the risk of failure and minimizing maintenance requirements.

The combination of high-quality materials and precise manufacturing processes results in seal faces capable of withstanding aggressive fluids, abrasive particles, and harsh operating conditions. Flygt Mechanical Seals maintain their integrity over time, delivering reliable performance for even the most demanding applications.

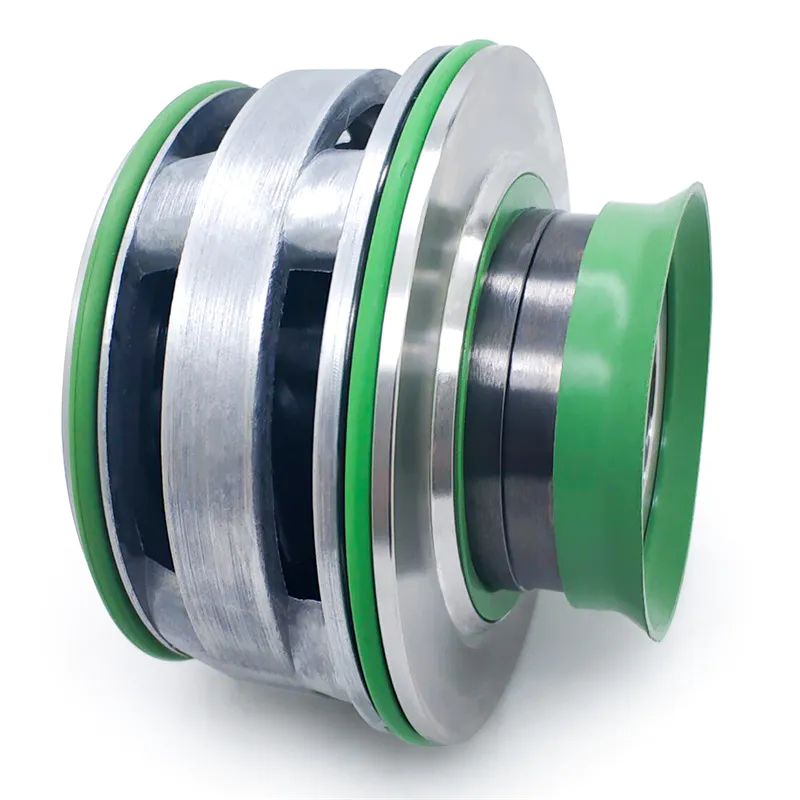

2. Intelligent Seal Design

Flygt's commitment to innovation is evident in their intelligent seal design. By incorporating state-of-the-art features, they have tackled common seal leakage challenges experienced in pumping systems.

One remarkable innovation is the use of wave-spring technology. This design ensures consistent seal face loading, minimizing face-to-face contact and reducing wear. Additionally, the wave-spring technology compensates for face wear, extending the seal life and optimizing system performance.

Another aspect of Flygt's seal design is the incorporation of seal face cooling. In applications where the pumped fluid has poor lubricating properties or the process generates heat, cooling jackets and flush ports can be added to maintain the seal face within a safe temperature range. This prevents seal face damage due to overheating and extends seal life.

3. Robust Secondary Sealing Mechanisms

Flygt understands the importance of reliable secondary sealing mechanisms in preventing seal leakage. Their mechanical seals utilize advanced elastomer technologies, such as fluorocarbon and nitrile rubber, to ensure effective static and dynamic sealing.

The elastomers are carefully selected to withstand chemical exposure, pressure differentials, and temperature extremes. Combined with precision engineering, Flygt's secondary sealing mechanisms provide exceptional performance, reducing the risk of leakage even in challenging operating conditions.

4. Modular Design for Easy Installation and Maintenance

Simplicity and efficiency are key considerations when implementing mechanical seals in pumping systems. Flygt acknowledges this by offering a modular design that enables quick and hassle-free installation.

The seals are designed to fit a wide range of pump models, allowing for straightforward replacement or retrofitting. By reducing downtime during seal installation and maintenance procedures, Flygt Mechanical Seals help optimize productivity and minimize operational disruptions.

5. Extensive Application Coverage

Flygt caters to a diverse range of industries and pumping applications. Whether you require a mechanical seal for wastewater treatment, mining operations, chemical processing, or any other sector, Flygt has a solution tailored to your specific needs.

Their comprehensive product range encompasses different seal types, sizes, and materials, ensuring compatibility with various pump configurations and operating conditions. From low-pressure applications to high-performance demands, Flygt Mechanical Seals deliver exceptional reliability and sealing performance.

Summarizing the Benefits

In conclusion, Flygt Mechanical Seals are engineered to address seal leakage challenges in pumping systems effectively. By offering enhanced seal face materials, intelligent seal design, robust secondary sealing mechanisms, modular installation features, and extensive application coverage, Flygt ensures reliable and long-lasting sealing solutions.

Opting for Flygt Mechanical Seals means investing in leak-free operations, increased energy efficiency, extended equipment lifespans, and minimized maintenance costs. Don't let seal leakage compromise your pumping system's performance—trust Flygt to safeguard your operations and keep fluids where they belong.

With Flygt Mechanical Seals, you can bid farewell to seal leakage challenges and enjoy uninterrupted, efficient pumping operations.