Exploring Cutting-Edge Materials for Flygt Mechanical Seal Construction

Exploring Cutting-Edge Materials for Flygt Mechanical Seal Construction

Introduction

The Importance of Flygt Mechanical Seals

Advancements in Seal Design: A Brief Overview

1. The Evolution of Flygt Mechanical Seals

2. Innovations in Seal Materials

3. Enhancing Performance: Factors to Consider

4. Future Prospects: Promising Materials for Flygt Mechanical Seals

Conclusion

Introduction

Mechanical seals are essential components in various industrial applications, ensuring the efficient operation of pumps and eliminating leakage issues. Among the most reputable manufacturers of mechanical seals is Flygt, known for their dedication to innovation and quality. This article sheds light on the significance of Flygt mechanical seals, explores the evolution of seal materials, and delves into cutting-edge advancements in seal construction.

The Importance of Flygt Mechanical Seals

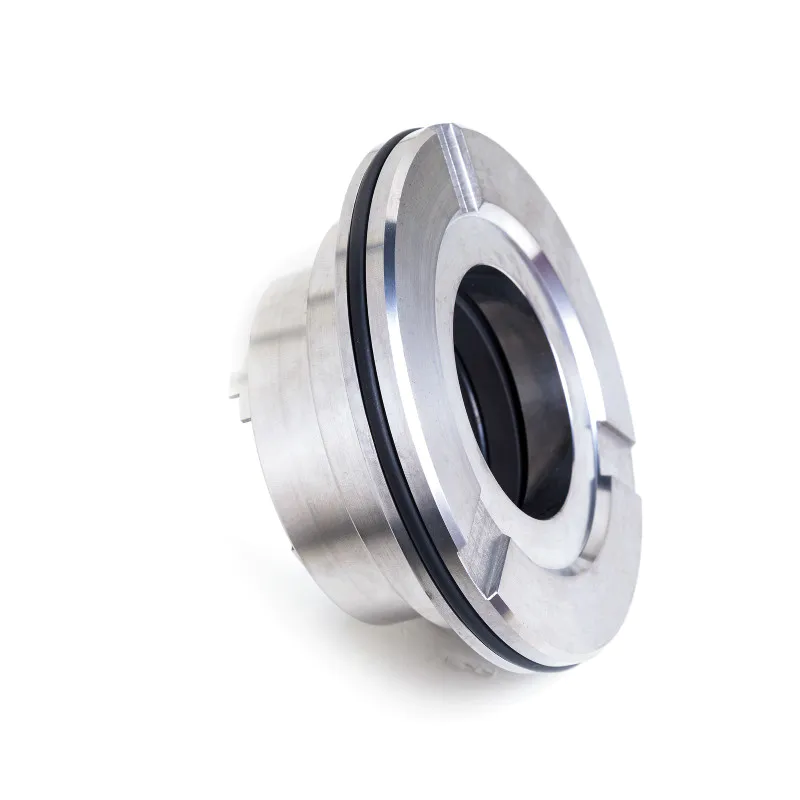

Mechanical seals play a vital role in improving the performance and reliability of pumps. They act as a barrier between the rotating and stationary parts of a pump, preventing the leakage of fluids and protecting the environment from contamination. Flygt mechanical seals are recognized for their durability, longevity, and ability to withstand harsh operating conditions, making them a preferred choice for numerous industries such as wastewater treatment, mining, oil and gas, and chemical processing.

Advancements in Seal Design: A Brief Overview

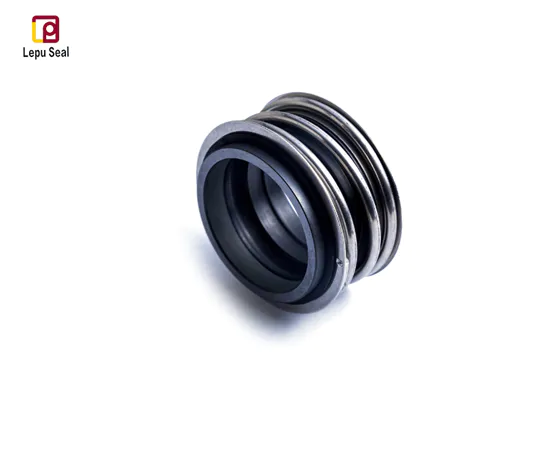

Over the years, seal manufacturers have continuously strived to develop innovative designs that enhance seal performance and extend their operational life. Gone are the days of traditional packing glands, as mechanical seals have emerged as the go-to solution. From single mechanical seals to double or tandem seals and cartridge seals, the sealing industry has witnessed phenomenal growth in terms of design diversity and sealing technology.

1. The Evolution of Flygt Mechanical Seals

Flygt, being a leader in the industry, has made significant contributions to the evolution of mechanical seals. Their continuous research and development efforts have resulted in seals with improved sealing capabilities, reduced maintenance requirements, and enhanced reliability. Flygt's seals have evolved from basic designs to advanced ones, integrating cutting-edge materials for increased efficiency and performance.

2. Innovations in Seal Materials

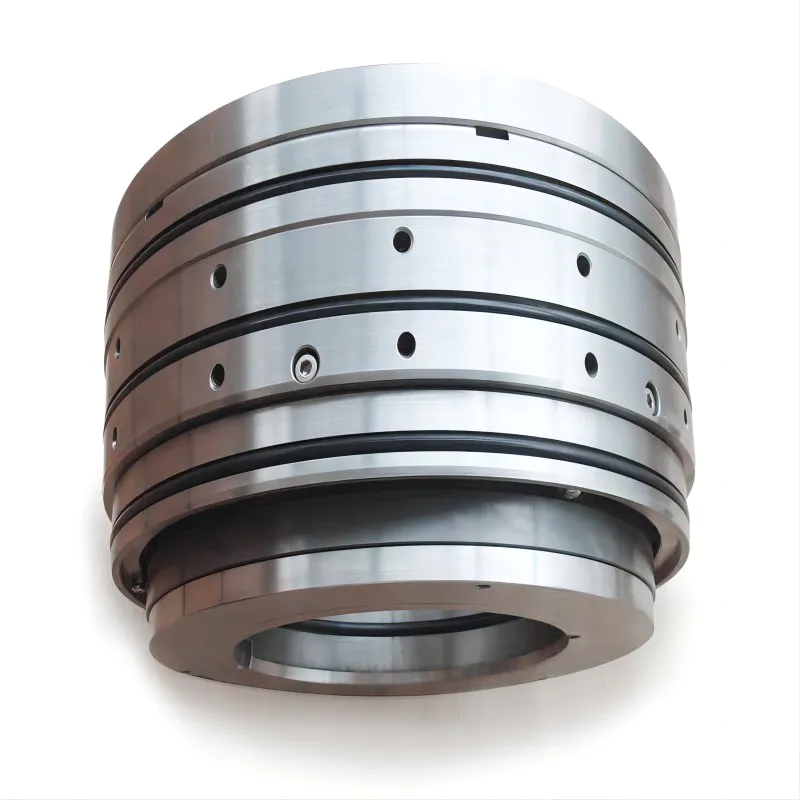

One of the key factors in enhancing the effectiveness of mechanical seals is the choice of materials used in their construction. Traditionally, seals were primarily made of materials such as carbon, ceramics, and stainless steel. However, with advancements in material science, researchers have explored new possibilities, incorporating innovative materials that exhibit superior mechanical properties and chemical resistance.

Flygt, in collaboration with material scientists, has identified and implemented novel materials such as silicon carbide, tungsten carbide, and various advanced ceramics. These materials offer excellent wear resistance, higher thermal conductivity, and greater hardness compared to their conventional counterparts. Such innovations have resulted in seals that can withstand high pressures, handle abrasive media, and operate at elevated temperatures without compromising performance.

3. Enhancing Performance: Factors to Consider

While incorporating cutting-edge materials is crucial, optimizing the performance of Flygt mechanical seals encompasses various other factors as well. The design and engineering of the seal elements, such as seal faces, springs, and elastomers, are equally important. The proper selection and combination of these components can significantly impact the overall performance and longevity of the seal.

Additionally, factors such as lubrication, environmental conditions, and operating parameters play a key role in determining seal performance. The advancement of sealing technologies has led to the development of seals capable of handling corrosive environments, providing better lubrication, and operating seamlessly under extreme conditions, further cementing Flygt's reputation as an industry leader.

4. Future Prospects: Promising Materials for Flygt Mechanical Seals

As technology progresses, researchers are continuously exploring new materials and incorporating them into seal designs to push the boundaries of performance. In recent years, materials like carbon-graphene composites and nano-coatings have emerged as potential game-changers.

Carbon-graphene composites offer exceptional strength, wear resistance, and thermal conductivity, making them a prime candidate for next-generation mechanical seals. These materials have the potential to revolutionize the field, enabling seals to operate under extreme conditions and provide unparalleled reliability.

Nano-coatings, on the other hand, exhibit remarkable self-lubricating properties, reducing friction and wear between seal faces. By incorporating these coatings into Flygt mechanical seals, the need for additional lubrication can be minimized, further improving seal performance and reducing maintenance requirements.

Conclusion

In conclusion, Flygt mechanical seals have significantly contributed to the advancement of sealing technology. Through continuous research and innovation, Flygt has explored cutting-edge materials and seal designs, resulting in seals that offer enhanced performance, increased reliability, and longer operational lifespan. The future of mechanical seals looks promising, with the integration of materials like carbon-graphene composites and nano-coatings on the horizon, allowing for even greater efficiency and performance in the years to come.