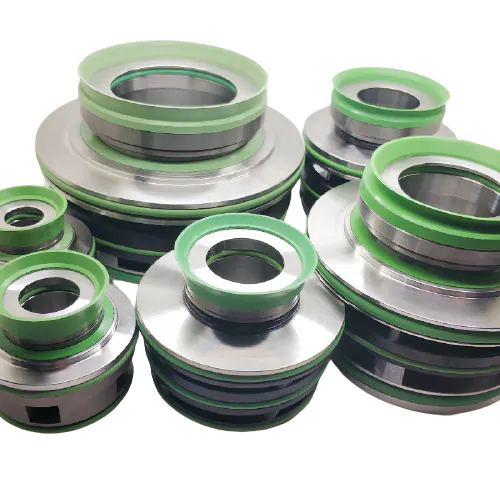

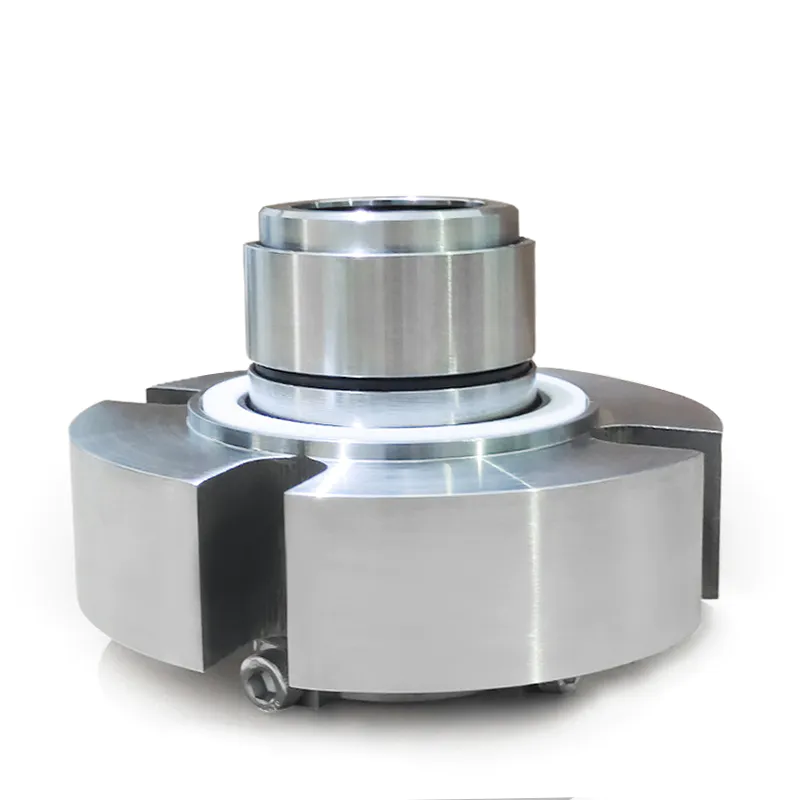

Enhancing Pump Reliability with High-Quality Tungsten Carbide Seal Rings

Pumps are essential equipment in various industries, ranging from water treatment plants to oil refineries. Ensuring the reliability and longevity of these pumps is crucial for smooth operations and avoiding costly breakdowns. One of the critical components in a pump is the seal ring, which helps maintain the integrity of the pump system by preventing leakage. In recent years, there has been a growing recognition of the benefits of using high-quality tungsten carbide seal rings to enhance pump reliability. These rugged and durable seal rings offer superior performance and extend the lifespan of pumps, making them an ideal choice for demanding applications. This article delves deeper into the advantages of using tungsten carbide seal rings and explains why they are the go-to solution for enhancing pump reliability.

The Importance of Pump Reliability

Pumps play a vital role in numerous industries, including manufacturing, mining, and agriculture, among others. They are responsible for efficiently transferring fluids, such as gases and liquids, from one location to another. Unreliable pumps can lead to disruptions in operations, decreased productivity, and even health and safety risks. Maintaining pump reliability is crucial to avoid costly downtime, repairs, and replacements. A well-functioning pump can save businesses substantial resources by reducing maintenance costs, energy consumption, and emergency repairs. Therefore, ensuring pump reliability is not just an investment in equipment, but also an investment in the overall efficiency and profitability of an operation.

Understanding Tungsten Carbide Seal Rings

Tungsten carbide seal rings are high-performance components designed to enhance the performance and durability of pumps. Tungsten carbide, a compound of tungsten and carbon, is renowned for its exceptional hardness and resistance to wear and corrosion. These properties make it an ideal material for seal rings that are subjected to high pressure, abrasive fluids, and extreme temperatures. Tungsten carbide seal rings are typically manufactured using powder metallurgy techniques, where fine tungsten carbide particles are mixed with a binder, compacted into a desired shape, and then sintered to form a solid, dense material.

The Benefits of Tungsten Carbide Seal Rings

The adoption of high-quality tungsten carbide seal rings brings several advantages that significantly enhance pump reliability and performance. These benefits include:

1. Improved Wear Resistance: Tungsten carbide seal rings offer unparalleled wear resistance, which is vital for pumps handling abrasive or corrosive fluids. The hardness and low friction coefficient of tungsten carbide help minimize wear on the sealing faces, ensuring a longer operating life for the pump.

2. Reduced Leakage: Pump leakage can lead to various issues, including loss of efficiency, contamination, and safety hazards. Tungsten carbide seal rings provide excellent sealing capabilities, minimizing the risk of fluid leakage and ensuring the pump operates at its full potential.

3. Enhanced Chemical Compatibility: Tungsten carbide exhibits exceptional chemical resistance, making it suitable for a wide range of fluid applications. It can withstand aggressive chemicals, acids, and alkalis, ensuring the seal rings remain intact and functional even in challenging environments.

4. Temperature and Pressure Resistance: Tungsten carbide can withstand extreme temperatures and high-pressure conditions that might cause failures with other seal ring materials. This resilience enables pumps with tungsten carbide seal rings to operate in demanding environments with confidence.

5. Extended Service Life: By incorporating tungsten carbide seal rings, pump reliability is significantly enhanced, ultimately resulting in an extended service life for the equipment. The inherent durability of tungsten carbide allows pumps to operate for prolonged periods without experiencing significant wear or loss of performance.

Applications of Tungsten Carbide Seal Rings

Tungsten carbide seal rings find applications in various pump systems across different industries. Some notable applications include:

1. Oil and Gas: The oil and gas industry operates in harsh and volatile conditions, and pump failure can have severe consequences. Tungsten carbide seal rings are widely used in pumps handling crude oil, natural gas, and drilling mud, where they provide exceptional reliability and resistance to abrasive particles.

2. Chemical Processing: Chemical plants often deal with corrosive and aggressive fluids, which can degrade conventional seal ring materials. Tungsten carbide seal rings offer the necessary chemical compatibility and durability to withstand harsh chemical environments, ensuring reliable operation in chemical processing pumps.

3. Mining and Slurry Handling: Mining operations involve the transportation of highly abrasive slurries. Tungsten carbide seal rings are specifically designed to withstand the abrasive wear caused by these slurries, providing reliable sealing in pumps used for ore processing, coal washing, and mineral slurries.

4. Water and Wastewater Treatment: Municipal water treatment plants and wastewater treatment facilities rely on pumps to handle large volumes of water and waste. Tungsten carbide seal rings offer exceptional wear resistance and can withstand the corrosive nature of chemicals used in water treatment, ensuring reliable operation with minimal downtime.

5. Food and Beverage: Pumps used in the food and beverage industry must comply with stringent hygiene standards. Tungsten carbide seal rings are FDA-approved and provide excellent resistance to chemicals used for cleaning and sanitizing, making them suitable for applications involving food and beverage processing.

In Summary

High-quality tungsten carbide seal rings have revolutionized pump reliability by offering improved wear resistance, reduced leakage, enhanced chemical compatibility, temperature and pressure resistance, and extended service life. These characteristics make tungsten carbide seal rings a top choice for industries operating in highly demanding environments. Whether it's the oil and gas sector, chemical processing plants, or mining operations, the implementation of tungsten carbide seal rings ensures pumps operate reliably, minimizing downtime, reducing maintenance costs, and optimizing efficiency. By investing in the reliability-enhancing capabilities of tungsten carbide seal rings, businesses can ensure smooth operations, increased productivity, and an overall competitive edge.