Enhancing Operational Safety with Dry Gas Seals in Power Generation Facilities

For power generation facilities, operational safety is of utmost importance. Any failures or disruptions in the equipment can not only lead to costly downtime but also pose significant risks to the environment and personnel. One critical component that plays a vital role in ensuring the safe and efficient operation of power generation facilities is the dry gas seal. Dry gas seals offer improved reliability, reduced emissions, and enhanced operational safety compared to conventional liquid seals. Let's delve deeper into the benefits and importance of dry gas seals in power generation facilities.

The Importance of Operational Safety in Power Generation Facilities

Operational safety is a top priority in power generation facilities due to the potentially hazardous nature of the operations involved. Ensuring the safety of personnel and safeguarding the environment are key responsibilities of power plant operators. Any operational failures can lead to severe consequences such as equipment damage, loss of power supply, and environmental pollution. Therefore, implementing technologies and practices that enhance operational safety is crucial to prevent accidents, minimize downtime, and ensure the continuous supply of electricity to meet the demands of communities and industries.

The Role of Dry Gas Seals in Power Generation Facilities

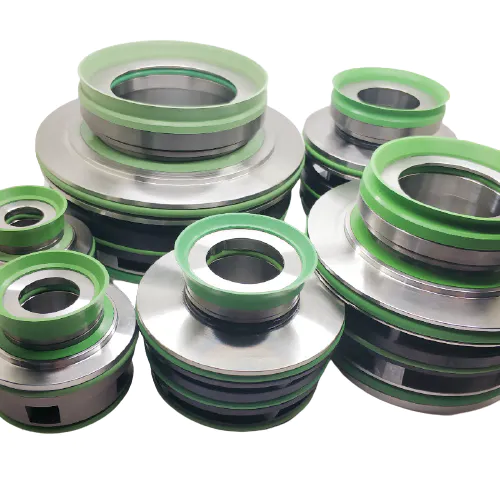

Dry gas seals are advanced sealing systems designed to provide a leakage-free sealing environment in power generation equipment such as compressors, turbines, and pumps. Unlike traditional liquid seals that rely on a liquid barrier, dry gas seals use a self-contained gas barrier to prevent leakage of process gas and lubricant. The use of dry gas seals offers several important advantages over liquid seals, including improved reliability, reduced maintenance requirements, and enhanced safety.

Enhanced Reliability

One of the primary benefits of dry gas seals is their enhanced reliability. Traditional liquid seals are prone to leakage due to wear and tear, contamination, and temperature fluctuations. On the other hand, dry gas seals are less susceptible to these issues. They are designed to operate with minimal contact between the seal faces, reducing wear and extending the seal's life. This enhanced reliability ensures uninterrupted operation and minimizes the risk of equipment failures and unplanned shutdowns.

Reduced Emissions

Dry gas seals play a crucial role in reducing emissions in power generation facilities. The prevention of gas leakage not only improves operational efficiency but also reduces the environmental impact. Leakage of process gas and lubricant can result in the release of harmful substances into the atmosphere, contributing to air pollution. By using dry gas seals, power plants can effectively contain the process gas and minimize emissions, helping to meet environmental regulations and sustainability goals.

Enhanced Operational Safety

The use of dry gas seals significantly enhances operational safety in power generation facilities. These seals provide a high level of containment, preventing the leakage of flammable or hazardous gases that could pose a risk to personnel and equipment. By ensuring a leakage-free sealing environment, dry gas seals minimize the potential for accidents, fires, or explosions caused by combustible gases. This enhances the overall safety of the facility and protects both the plant personnel and the surrounding community.

Reduced Maintenance Requirements

Dry gas seals also offer the advantage of reduced maintenance requirements compared to traditional liquid seals. Liquid seals require regular maintenance, including lubrication, monitoring, and replacement, which can be time-consuming and costly. Dry gas seals, on the other hand, have a longer operational lifespan and require minimal maintenance. The simplicity of their design, absence of liquid components, and reduced wear make them less prone to failure. This reduces the need for frequent seal replacement and maintenance, leading to cost savings and increased operational efficiency.

Conclusion

Operational safety is a critical consideration in power generation facilities, and dry gas seals play a vital role in enhancing safety and reliability. These advanced sealing systems offer numerous benefits, including improved reliability, reduced emissions, enhanced operational safety, and reduced maintenance requirements. By incorporating dry gas seals into their equipment, power generation facilities can achieve greater operational efficiency, minimize downtime, and ensure a safer environment for their personnel and surrounding communities. As the demand for electricity continues to grow, the implementation of technologies that enhance operational safety will be essential to meet the evolving needs of the power industry.