Enhancing Gas Turbine Efficiency with Tandem Dry Gas Seals

Enhancing Gas Turbine Efficiency with Tandem Dry Gas Seals

Introduction:

Modern industries heavily rely on gas turbines for their power generation needs. These turbines are highly efficient and can deliver consistent power. However, as technology advances and energy demands increase, the search for new ways to enhance gas turbine efficiency becomes ever more critical. One promising solution that has gained significant attention is the implementation of tandem dry gas seals. This article explores how tandem dry gas seals can significantly improve gas turbine efficiency and discusses their advantages over conventional sealing systems.

Understanding Gas Turbines and their Operation:

Before delving into the benefits of tandem dry gas seals, it is essential to understand the working principles of gas turbines. Gas turbines, commonly used in power plants, aircraft engines, and industrial plants, operate on the Brayton cycle.

The Brayton cycle consists of the following four sequential processes:

1. Intake: Ambient air is drawn into the compressor.

2. Compression: The compressor raises the air pressure before it enters the combustion chamber.

3. Combustion: Fuel is mixed with compressed air, ignited, and burned in the combustion chamber, producing high-temperature, high-pressure gases that expand.

4. Power generation: The gases expand through the turbine, extracting energy to drive the compressor and generate power.

Gas turbines employ sophisticated machinery to achieve high efficiency. However, sealing systems pose a significant challenge as they need to maintain a reliable, leak-free environment while withstanding high temperatures and pressures.

The Importance of Effective Sealing Systems:

A gas turbine's overall efficiency depends on several factors, and supply and control of air and fuel are crucial. Efficient sealing is paramount to prevent air leakage during compression and fuel leakage during combustion, as both disrupt the energy conversion process and decrease overall efficiency. Traditional labyrinth and brush sealing systems have limitations and can compromise efficiency.

Introducing Tandem Dry Gas Seals:

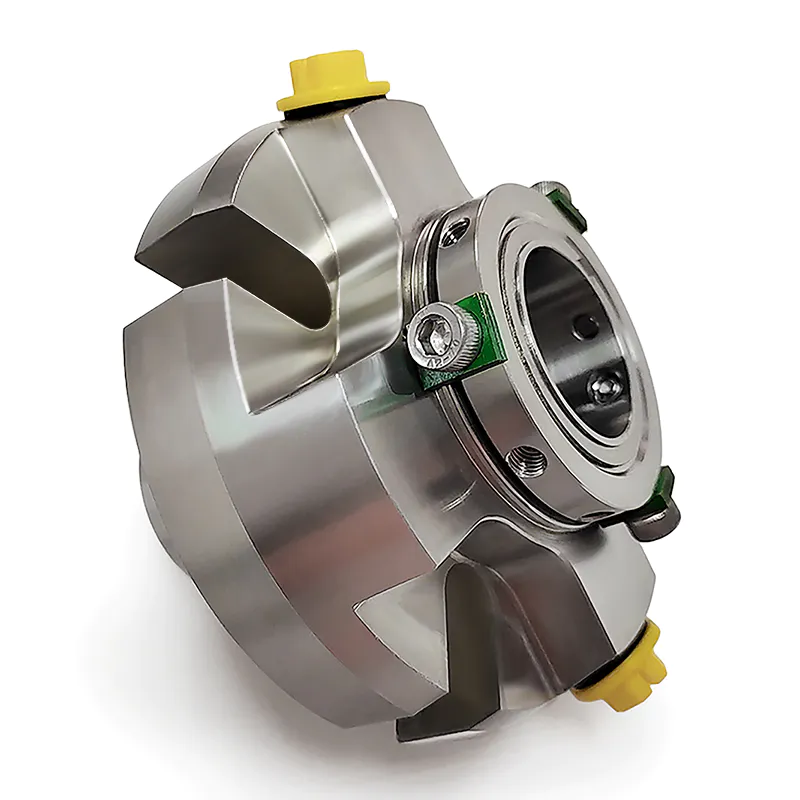

Tandem dry gas seals are an innovative sealing technology that offers several advantages over conventional sealing systems. These advanced seals consist of two or more stages of sealing, working in tandem to provide an enhanced sealing performance. Compared to single-stage seals, tandem seals offer improved reliability, reduced leakage rates, and increased overall gas turbine efficiency.

Advantages of Tandem Dry Gas Seals:

1. Enhanced Sealing Performance:

Tandem dry gas seals achieve a higher sealing capacity by maximizing the pressure differential across multiple stages. This approach ensures efficient sealing and minimizes gas leakage, reducing energy losses.

2. Reduced Emissions:

By minimizing leakage, tandem dry gas seals help reduce harmful emissions. Gas turbines equipped with tandem seals contribute to environmental sustainability by achieving lower levels of greenhouse gas emissions.

3. Improved Reliability:

Tandem seals provide an added layer of reliability due to their redundant design. In the event of a failure in one stage, the remaining stages continue to function, maintaining the overall integrity of the sealing system. This redundancy improves operational safety and prevents cost-intensive downtimes.

4. Higher Resistance to Contaminants:

Tandem seals are less prone to contamination and particulate fouling due to their self-cleaning design. This self-cleaning mechanism prevents debris buildup and increases the system's longevity, reducing maintenance requirements and associated costs.

5. Flexibility in Design:

Tandem dry gas seals are flexible and can be tailored to fit various gas turbine configurations, accommodating specific operational requirements. Their versatile design allows for easy integration, making them suitable for both retrofitting existing systems and incorporating into newly designed turbines.

Conclusion:

As industries strive for greater energy efficiency and environmental sustainability, the implementation of tandem dry gas seals heralds a new era for gas turbine sealing systems. With enhanced sealing performance, reduced emissions, improved reliability, resistance to contaminants, and design flexibility, tandem seals are a promising solution to maximize gas turbine efficiency. Their incorporation into gas turbine systems will contribute to a greener future while ensuring consistent and reliable power generation.