EagleBurgmann Mechanical Seals: Sealing for a Sustainable Future

EagleBurgmann Mechanical Seals: Sealing for a Sustainable Future

Introduction:

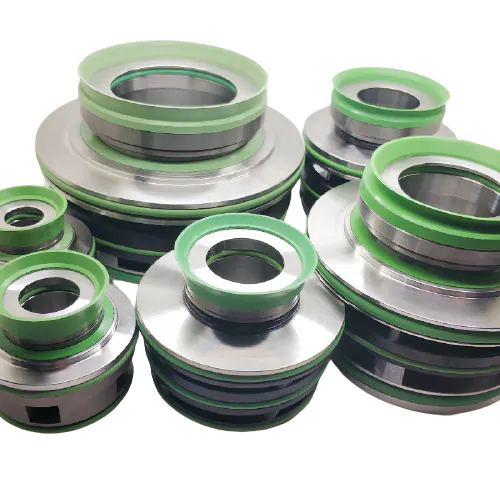

In our ever-evolving world, innovation and sustainability go hand in hand. When it comes to industrial machinery, one crucial element that ensures efficient operation and minimal environmental impact is mechanical seals. EagleBurgmann, a leading global provider of sealing solutions, has been at the forefront of developing cutting-edge mechanical seals that promote sustainability. In this article, we delve into the technology behind EagleBurgmann's mechanical seals and explore how they contribute to a more sustainable future.

1. The Role of Mechanical Seals in Industrial Machinery:

Industrial machinery, such as pumps, compressors, and agitators, rely on mechanical seals to prevent leakage, reduce energy consumption, and prolong the equipment's lifespan. Mechanical seals act as a barrier between two distinct areas of a machine, containing fluids or gases under pressure while preventing external contamination. Traditional sealing solutions often encountered issues such as excessive leakage, frictional losses, and high maintenance costs. EagleBurgmann's mechanical seals address these challenges with innovative designs and advanced materials.

2. Enhancing Efficiency and Reducing Energy Consumption:

One significant advantage of EagleBurgmann's mechanical seals is their ability to improve overall energy efficiency. By minimizing leaks and maintaining optimal operating conditions, the seals prevent energy losses that result from system inefficiencies. This not only reduces the carbon footprint of industrial operations but also leads to substantial cost savings. Additionally, EagleBurgmann's seals are engineered to withstand high-pressure and high-temperature environments, ensuring reliable performance under demanding conditions.

3. Sustainable Materials and Manufacturing:

EagleBurgmann's commitment to sustainability extends beyond performance to the materials used in their seals and the manufacturing processes. The company emphasizes the use of eco-friendly materials that are safe for both operators and the environment. By opting for sustainable materials, such as non-toxic elastomers and low-friction coatings, EagleBurgmann ensures that their seals meet stringent environmental standards. Furthermore, the company has implemented environmentally conscious manufacturing practices that minimize waste generation and reduce energy consumption in production facilities.

4. Extending Equipment Lifespan and Reducing Maintenance:

Mechanical seals play a vital role in extending the lifespan of industrial equipment. By effectively sealing and protecting the equipment from contaminants, EagleBurgmann's seals help prevent premature wear and costly breakdowns. With longer equipment lifecycles, industries can reduce the need for frequent replacements, minimizing both material consumption and waste generation. Furthermore, the advanced design of EagleBurgmann's mechanical seals reduces the need for regular maintenance, resulting in increased operational efficiency and reduced downtime.

5. Addressing Environmental Challenges in Specific Industries:

Different industries face unique environmental challenges that require specialized sealing solutions. EagleBurgmann caters to various sectors, providing tailored mechanical seal solutions that address specific industry requirements. For instance, in the oil and gas industry, where leakage can have severe environmental consequences, EagleBurgmann's seals boast superior sealing capabilities, withstand abrasive and corrosive substances, and operate flawlessly under extreme pressure conditions. Similarly, in the pharmaceutical sector, EagleBurgmann offers customized seals that ensure product purity, preventing contamination and maintaining the highest quality standards.

6. Collaborating for a Sustainable Future:

EagleBurgmann recognizes that creating a sustainable future requires collaboration with industry partners, customers, and regulatory bodies. The company actively engages in research and development initiatives to stay ahead of emerging trends and align its sealing solutions with evolving industry requirements. By fostering partnerships with customers, EagleBurgmann gains valuable insights into their specific needs and can co-create innovative sealing solutions that are both sustainable and performance-driven. Additionally, the company actively participates in industry associations and regulatory dialogues, contributing to the development of global sustainability standards.

Conclusion:

EagleBurgmann's mechanical seals are a testament to the company's commitment to sustainability. By providing efficient sealing solutions that mitigate environmental impact and ensure optimal equipment performance, EagleBurgmann contributes to a more sustainable future across various industries. As the world continues to prioritize eco-friendly practices, EagleBurgmann's mechanical seals become an indispensable tool in safeguarding the environment while promoting operational efficiency. With their continued focus on innovation, collaboration, and sustainability, EagleBurgmann paves the way for a greener industrial landscape.