EagleBurgmann Dry Gas Seals in Power Generation: Efficiency and Safety

EagleBurgmann Dry Gas Seals in Power Generation: Efficiency and Safety

Introduction:

Gas turbine technology has revolutionized the power generation industry, providing efficient and reliable solutions for electricity production. As power demands continue to climb, it is imperative to optimize turbine performance, ensuring both efficiency and safety. In this regard, EagleBurgmann's dry gas seals have emerged as a game-changer in power generation. This article delves into the key aspects of these innovative seals and their contributions to enhancing efficiency and safety in the power generation sector.

I. Understanding Gas Seals in Power Generation

Gas seals play a crucial role in maintaining efficiency and preventing leakages in gas turbines. Traditionally, oil-lubricated seals were the norm, but their drawbacks prompted the development of dry gas seals. These next-generation seals eliminate the need for oil lubrication, mitigating the risks associated with oil leakages and contamination. EagleBurgmann's dry gas seals have gained recognition for their ability to minimize downtime, improve performance, and enhance safety in power generation.

II. The Advantages of Dry Gas Seals

1. Enhanced Efficiency:

Dry gas seals offer superior performance compared to their oil-lubricated counterparts. By eliminating the need for oil, these seals reduce friction and mechanical losses, allowing for increased power output. The improved efficiency translates into cost savings, reduced carbon emissions, and optimized power generation operations.

2. Risk Mitigation:

One of the primary concerns in power generation is the risk of oil leakages. Oil-lubricated seals have been known to cause expensive downtime and environmental hazards due to leakages. EagleBurgmann's dry gas seals eliminate this risk by employing a non-contact design that prevents any contact between the rotating and stationary components. This design ensures reliable operation, minimizing the potential for costly equipment failures and related safety hazards.

III. Seal Design and Operation

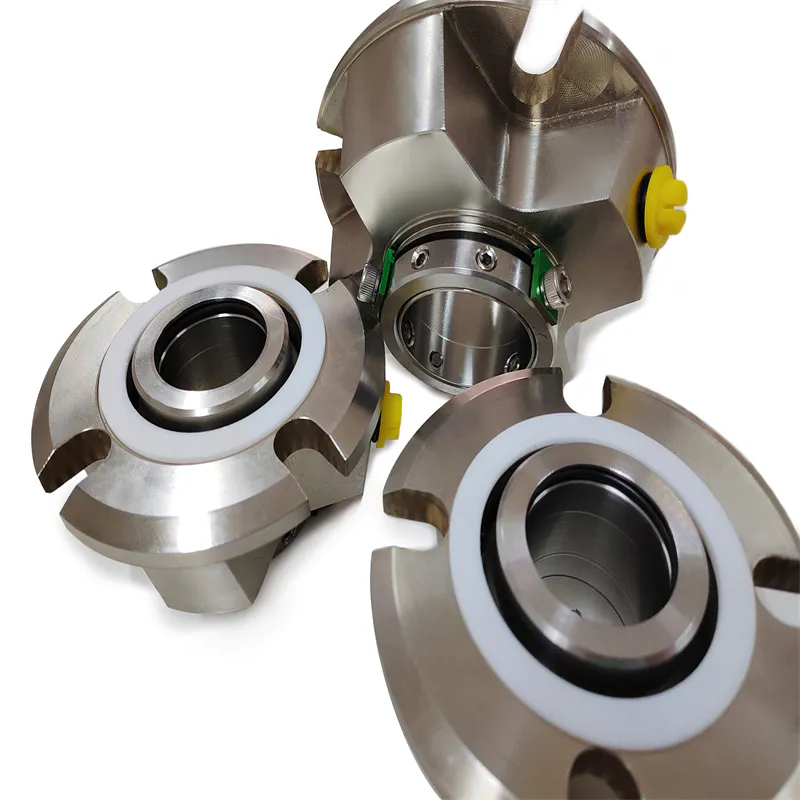

EagleBurgmann's dry gas seals are designed to withstand extreme conditions prevalent in power generation environments. These seals consist of primary and secondary rings, both featuring carefully engineered materials and clever geometries. The primary ring, situated on the shaft, prevents the leakage of process gas, while the secondary ring serves as an additional safety barrier. The hydrodynamic lift-off of the secondary ring ensures reliable sealing during transient operating conditions.

IV. Cutting-Edge Technology for Optimal Performance

1. Advanced Materials:

EagleBurgmann utilizes state-of-the-art materials to ensure longevity and performance of their dry gas seals. The use of high-grade materials, such as Silicon Carbide and Diamond-Like Carbon coatings, enhances wear resistance and reduces the risk of sealing failures. These abrasion-resistant materials enable the seals to operate flawlessly under challenging conditions, thereby improving the overall efficiency and reliability of power generation systems.

2. Innovative Cooling Systems:

Efficient cooling is crucial for gas turbine components, as high temperatures can negatively impact equipment performance. EagleBurgmann's dry gas seals incorporate advanced cooling mechanisms to manage temperature rise effectively. By utilizing external cooling fans or air purge systems, these seals maintain optimal operating temperatures, reducing the risk of seal degradation and subsequent equipment failures.

V. Maintenance and Service Considerations

1. Predictive Maintenance:

EagleBurgmann's dry gas seals are designed for easy maintenance, resulting in minimal downtime. Additionally, the integration of advanced monitoring and diagnostic systems allows for predictive maintenance. By continuously monitoring seal condition and performance, power generation operators can proactively address any potential issues before they escalate, ensuring uninterrupted production and preventing costly repairs.

2. Expert Support:

EagleBurgmann provides comprehensive support services for their dry gas seals, including installation and commissioning assistance, regular maintenance recommendations, and technical troubleshooting. These expert services ensure that power generation professionals have access to the necessary knowledge and resources to optimize the efficiency and safety of their gas turbine systems.

Conclusion:

EagleBurgmann's dry gas seals have significantly contributed to the efficiency and safety of power generation operations worldwide. Through their advanced design, cutting-edge materials, and comprehensive maintenance support, these seals deliver enhanced performance, reduced downtime, and improved safety. As the energy landscape evolves, EagleBurgmann continues to innovate, propelling the power generation industry into a cleaner, more efficient future.