Double Cartridge Mechanical Seals in Submersible Pumps: Sealing Under Pressure

Double Cartridge Mechanical Seals in Submersible Pumps: Sealing Under Pressure

Introduction:

Submersible pumps play a vital role in various industries where liquids need to be transferred from one place to another. These pumps work under extreme operational conditions, including high pressures and continuous submergence. To ensure the efficient and reliable functioning of submersible pumps, a robust sealing mechanism is crucial. This article explores the significance of double cartridge mechanical seals in submersible pumps, their working principle, advantages, common challenges, and maintenance requirements.

I. Understanding Double Cartridge Mechanical Seals:

A. Definition and Purpose:

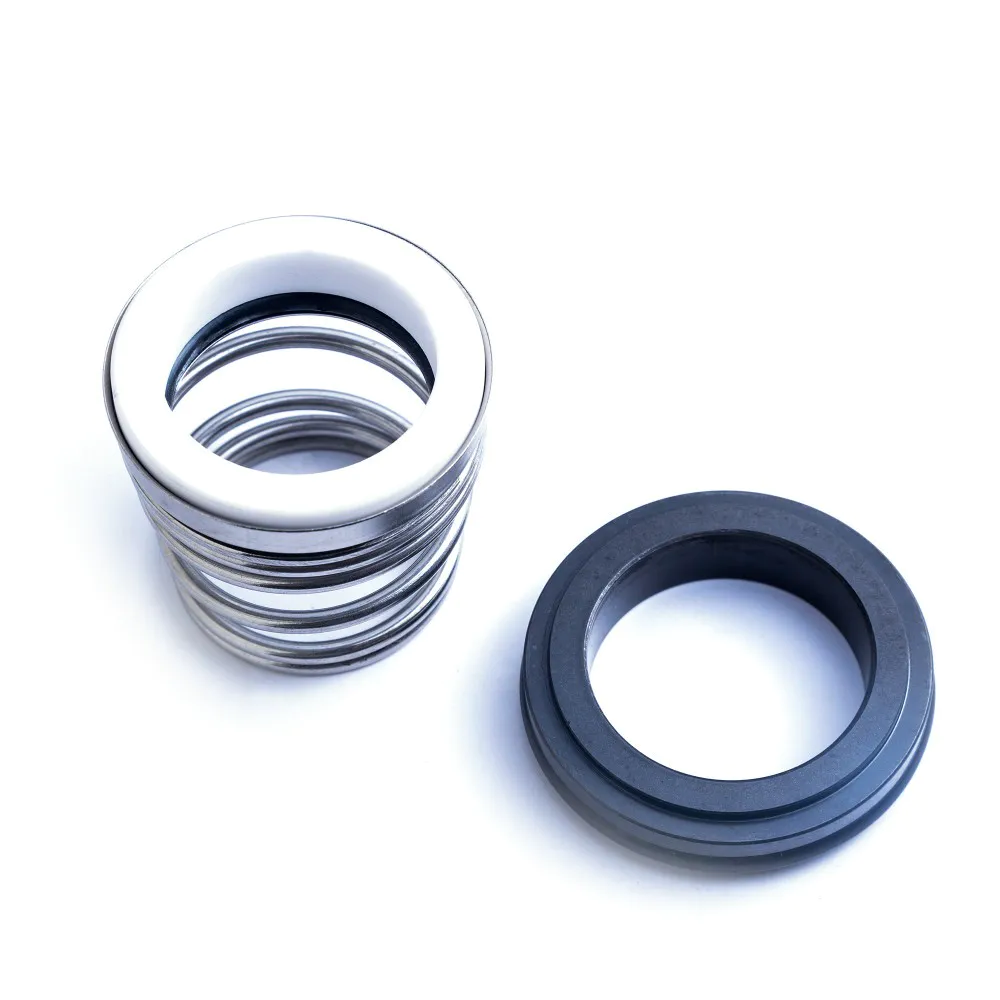

Double cartridge mechanical seals are advanced sealing systems designed specifically for submersible pumps. These seals consist of two identical seal faces mounted face-to-face in a single housing, allowing them to handle higher pressures and provide enhanced sealing capabilities.

B. Working Principle:

1. Primary Seal: The primary seal faces are in direct contact with the pumped fluid, ensuring a leak-free transfer. These faces create a tight seal, preventing any liquid from escaping the pump.

2. Secondary Seal: The secondary seal acts as a backup, providing an additional layer of protection against leakage. It prevents the process liquid from reaching the primary seal faces, safeguarding them from wear and damage.

C. Material Selection:

The selection of materials for double cartridge mechanical seals is crucial to ensure compatibility with the pumped fluids. Common materials include stainless steel, carbon, silicon carbide, and various elastomers, depending on the specific application requirements.

II. Advantages of Double Cartridge Mechanical Seals in Submersible Pumps:

A. Enhanced Reliability:

The double cartridge design improves the reliability of submersible pumps by providing redundancy in the sealing mechanism. Even if one seal face fails, the secondary seal takes over, preventing catastrophic leakage.

B. Higher Pressure Handling:

Submersible pumps often operate at high pressures. Double cartridge mechanical seals are specifically designed to handle these extreme pressure conditions without compromising sealing performance.

C. Reduced Maintenance:

The robust design and enhanced sealing capabilities of double cartridge mechanical seals result in reduced maintenance requirements. This reduces downtime and increases the overall operational efficiency of the submersible pumps.

D. Increased Seal Lifespan:

Compared to traditional single seals, double cartridge mechanical seals have a longer lifespan. The utilization of two identical seals minimizes wear on individual faces, extending the overall life of the sealing system.

III. Common Challenges and Solutions:

A. Seal Failure Due to High Solids:

Submersible pumps often handle fluids with high solid content, leading to abrasive wear on seal faces. To counter this challenge, special seal materials with superior wear resistance, such as silicon carbide, can be used.

B. Chemical Compatibility Issues:

In certain industries, submersible pumps handle aggressive chemicals that may degrade standard seal materials. In such cases, chemical-resistant materials must be carefully selected to ensure compatibility and maintain sealing integrity.

C. Cooling and Lubrication in Dry Run Conditions:

When submersible pumps operate in dry run conditions, cooling and lubrication become critical to prevent seal damage. Auxiliary systems such as water or oil circulation units can be implemented to maintain optimal operating temperatures and prevent premature seal failure.

IV. Maintenance and Repair:

A. Regular Inspection:

Periodic inspection of double cartridge mechanical seals is essential to identify any signs of wear, damage, or misalignment. This allows proactive maintenance before a failure occurs, preventing costly downtime.

B. Seal Face Cleaning and Polishing:

Accumulation of debris or solids on seal faces can compromise the sealing capabilities. Proper cleaning and polishing of seal faces promote longer seal life and enhance the overall efficiency of submersible pumps.

C. Correct Installation and Alignment:

Proper installation and alignment of double cartridge mechanical seals ensure optimal performance. This includes correct positioning, applied torque, and alignment with the pump shaft, minimizing the chances of premature failure.

D. Prompt Replacement:

In case of seal failure, prompt replacement is crucial to avoid extended downtime. Having spare double cartridge mechanical seals readily available can significantly reduce the impact of unexpected failures.

Conclusion:

Double cartridge mechanical seals offer a reliable and efficient sealing solution for submersible pumps operating in demanding environments. With their enhanced sealing capabilities and ability to handle high pressures, these seals provide improved operational reliability, reduced maintenance efforts, and increased lifespan. By understanding their working principle, advantages, and maintenance requirements, industries can optimize the performance and efficiency of their submersible pump systems.