Case Studies: Success Stories with Tandem Dry Gas Seals

Case Studies: Success Stories with Tandem Dry Gas Seals

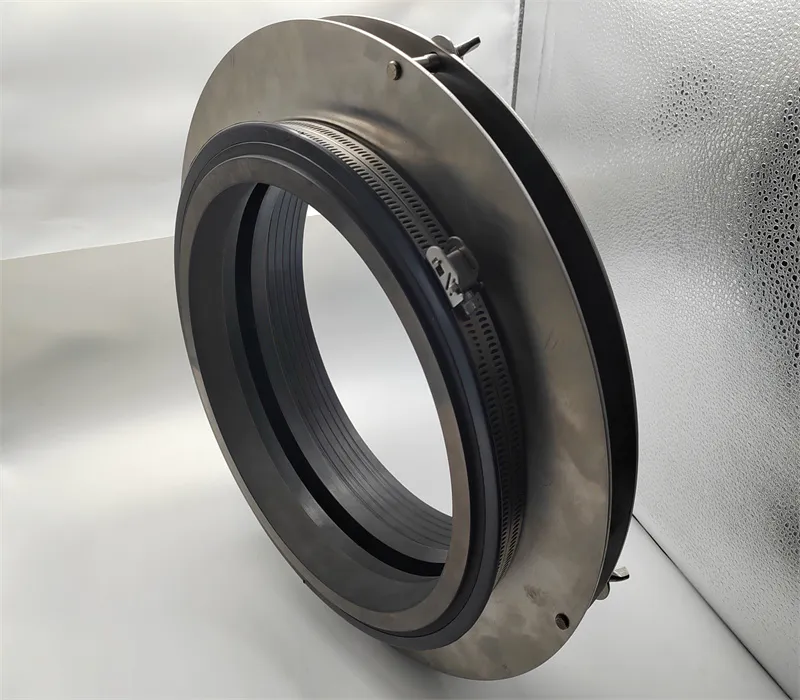

In the world of industrial equipment, achieving success stories is a testament to the efficiency and reliability of a particular product or technology. One such success story lies in the realm of Tandem Dry Gas Seals, which have revolutionized the sealing industry with their exceptional performance and numerous advantages. This article delves into the remarkable accomplishments of Tandem Dry Gas Seals through a series of case studies that highlight their unique capabilities and impact on various industries.

Case Study 1: Oil Refineries - Eliminating Leakage, Enhancing Safety

Oil refineries operate under extreme conditions, with high temperatures, volatile substances, and demanding pressure levels. Traditional sealing solutions often fell short in these challenging environments, leading to leakage and safety concerns. However, when Tandem Dry Gas Seals were implemented, significant improvements were observed. These seals effectively eliminated leakage issues and enhanced overall safety standards. By preventing the escape of flammable and hazardous gases, Tandem Dry Gas Seals have become an indispensable component in the oil refinery sector, ensuring both worker safety and operational efficiency.

Case Study 2: Power Generation Plants - Increasing Reliability, Reducing Downtime

Power generation plants, be it thermal or nuclear, require uninterrupted operations to meet the ever-increasing global energy demand. Any downtime directly impacts energy supply and financial stability. Tandem Dry Gas Seals have played a crucial role in increasing the reliability of key equipment. By providing an effective barrier against gas leakage, these seals have minimized the risk of unplanned shutdowns, thereby reducing downtime and maximizing productivity. This success story signifies the significant contribution of Tandem Dry Gas Seals in the power generation industry.

Case Study 3: Chemical Processing Facilities - Enhancing Performance, Decreasing Environmental Impact

The chemical processing industry operates in an environment where even the smallest deviations can have severe consequences. Tandem Dry Gas Seals have propelled this sector towards enhanced performance and reduced environmental impact. By preventing the release of harmful gases, these seals contribute to a cleaner and safer working environment. Moreover, improved sealing efficiencies of Tandem Dry Gas Seals have resulted in enhanced process stability, minimizing wastage and optimizing resource utilization. This case study highlights the sustainable benefits that these seals bring to chemical processing facilities.

Case Study 4: Marine Applications - Ensuring Seaworthy Conditions, Cutting Maintenance Costs

Marine applications, such as offshore drilling rigs and shipping vessels, require seals that can withstand harsh seawater environments while ensuring the integrity of critical equipment. Tandem Dry Gas Seals have proven their worth in these demanding scenarios. By providing robust resistance against corrosion and preventing seawater ingress, these seals ensure seaworthy conditions and extend the lifespan of essential machinery. Additionally, the reduction in maintenance requirements due to the reliability of Tandem Dry Gas Seals translates into significant cost savings for the maritime industry.

Case Study 5: Pharmaceutical Industry - Safeguarding Product Quality, Reducing Contamination Risks

In the pharmaceutical industry, maintaining product quality and adhering to strict regulations are of utmost importance. Tandem Dry Gas Seals have emerged as a highly valuable asset, safeguarding pharmaceutical products against contamination risks. By sealing equipment effectively, these seals prevent the ingress of unwanted particles, moisture, and impurities that could compromise product integrity. The success of Tandem Dry Gas Seals in the pharmaceutical sector is evident through improved product consistency, reduced wastage, and increased compliance with stringent industry standards.

Conclusion

The case studies presented here demonstrate the remarkable success stories associated with Tandem Dry Gas Seals. These seals have significantly impacted industries ranging from oil refineries to pharmaceuticals, ensuring improved safety standards, increased reliability, enhanced environmental performance, lowered maintenance costs, and safeguarding product quality. With every successful implementation, Tandem Dry Gas Seals solidify their reputation as a game-changing technology, revolutionizing the sealing industry one case study at a time.