Case Studies: Success Stories with Dry Gas Seals

Case Studies: Success Stories with Dry Gas Seals

Introduction

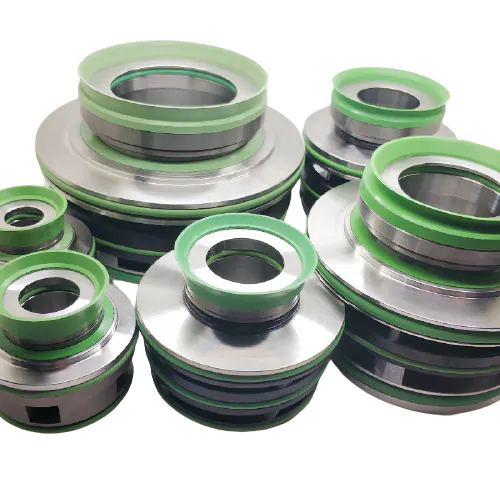

Dry gas seals have revolutionized the way industries deal with demanding sealing applications. With their outstanding performance and reliability, they have become an integral part of various industrial processes. This article will delve into the success stories of companies that have implemented dry gas seals, showcasing their exceptional outcomes. These case studies highlight the effectiveness and benefits that dry gas seals bring to diverse industries.

Enhancing Efficiency and Reducing Downtime in the Oil and Gas Industry

The oil and gas industry is notorious for its stringent requirements for equipment reliability and uninterrupted operations. In this case study, a large offshore oil rig implemented dry gas seals in its crucial compressor systems. The introduction of these seals not only eliminated the risk of leakage but also significantly reduced downtime associated with maintenance and repairs. By improving efficiency and reliability, the company witnessed a remarkable increase in production output, leading to a substantial boost in overall profitability.

Improving Environmental Sustainability in Chemical Processing Plants

Chemical processing plants often operate under conditions where emissions control and environmental sustainability are paramount. In this case study, a leading chemical plant integrated dry gas seals into their process compressors. These seals proved instrumental in curbing emissions and preventing the release of harmful gases into the environment. With reduced leakage and enhanced containment capabilities, the plant achieved compliance with strict environmental regulations while also reducing its carbon footprint. The success in environmental sustainability further bolstered the plant's reputation and attracted new business partners committed to eco-friendly operations.

Optimizing Performance in Power Generation Facilities

Power generation facilities face the challenge of maintaining optimal performance and minimizing power loss. In this case study, a large power plant incorporated dry gas seals in their gas turbines. These seals enhanced sealing effectiveness, which significantly reduced internal leakage and power losses. As a result, the facility experienced improved efficiency, ultimately leading to enhanced power output and cost savings. The success story of this power generation facility with dry gas seals demonstrates the potential for other plants to achieve similar gains in performance and profitability.

Pioneering Advancements in Aerospace Technology

The aerospace industry demands cutting-edge technologies to reinforce safety and reliability. In this case study, an aerospace company introduced dry gas seals in their jet engines to overcome the limitations of traditional oil-based seals. By adopting dry gas seals, the company dramatically reduced the risk of engine failure and increased engine efficiency. These advancements allowed for longer flight durations, reduced fuel consumption, and improved overall safety for aircraft and passengers. The story showcases the significant impact that dry gas seals have made in pushing the boundaries of aerospace technology.

Expanding Applications and Encouraging Innovation

As the reputation of dry gas seals continues to grow, innovative companies are exploring new applications. This case study examines a manufacturing company that successfully implemented dry gas seals in its specialized machinery, improving the sealing integrity and reducing maintenance requirements. This breakthrough inspired the company to experiment further and develop novel equipment with advanced sealing capabilities, driving innovation within the industry. The success of this company exemplifies how dry gas seals have become a catalyst for technological advancements across various sectors.

Conclusion

These case studies provide concrete evidence of the transformative power of dry gas seals across industries. From enhancing efficiency and reducing downtime in oil and gas operations to improving sustainability in chemical plants, optimizing performance in power generation facilities, pioneering advancements in aerospace technology, and inspiring innovation in manufacturing sectors, dry gas seals have proven their worth. It is evident that the adoption of dry gas seals can yield unparalleled benefits, from increased profitability and productivity to enhanced environmental sustainability and safety. As more success stories emerge, it is clear that the future holds even greater possibilities for the widespread utilization of dry gas seals.