Cartridge Seals vs. Component Seals: Choosing the Right Solution for Your Application

1. Introduction - Understanding the Importance of Sealing Solutions

2. Cartridge Seals Explained – Advantages and Applications

3. Component Seals - A Breakdown of their Features and Applications

4. Key Factors to Consider When Choosing between Cartridge Seals and Component Seals

5. Conclusion – Making the Right Decision for Your Specific Application

Introduction - Understanding the Importance of Sealing Solutions

When it comes to industrial applications such as pumps, compressors, and centrifuges, one crucial element that determines their efficiency and performance is the sealing solution used. The choice between cartridge seals and component seals plays a vital role in ensuring effective prevention of leaks, maintaining process efficiency, and maximizing equipment lifespan. In this article, we will dig deeper into the features, applications, and factors to consider when choosing between cartridge seals and component seals.

Cartridge Seals Explained – Advantages and Applications

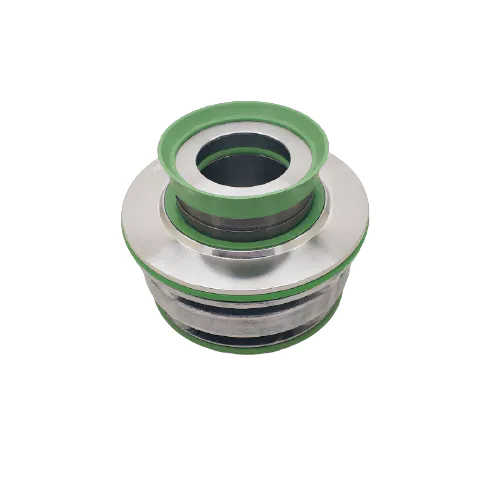

Cartridge seals are pre-assembled, self-contained sealing units that consist of a rotating part, a stationary part, and a gland plate. These seals are factory-tested, ensuring precise alignment and superior performance. One of the significant advantages of cartridge seals is their ease of installation. With their pre-assembled nature, they eliminate the need for measurements, adjustments, and individual part installation, saving valuable time during equipment maintenance or repair.

Furthermore, cartridge seals offer enhanced reliability as they reduce the risk of human error during installation. They provide a standardized sealing solution that can be easily replaced, ensuring consistent performance across multiple applications. These seals are commonly used in pumps, mixers, agitators, and other rotating equipment in various industries such as oil and gas, chemical processing, and water treatment.

Component Seals - A Breakdown of their Features and Applications

Component seals, unlike cartridge seals, are made up of individual parts that need to be assembled at the installation site. They consist of a rotating part, a stationary part, and auxiliary components like springs and pins. Component seals offer a high level of customization, allowing engineers to tailor the sealing solution to specific equipment requirements. They are available in a wide range of materials, face combinations, and sizes, making them suitable for diverse industrial applications.

Component seals provide flexibility in addressing challenging sealing situations. They can be adapted for high temperatures, aggressive chemicals, abrasive media, and unique operating conditions. However, the assembly process can be complex, requiring skilled personnel, careful measurements, and appropriate tooling. Therefore, component seals are commonly preferred when dealing with customized equipment, non-standard applications, or specific sealing requirements.

Key Factors to Consider When Choosing between Cartridge Seals and Component Seals

1. Ease of Installation and Maintenance: If quick and hassle-free installation and maintenance are a priority, cartridge seals offer distinct advantages. Since they are pre-assembled, they significantly reduce downtime and the chances of errors during installation. Component seals, on the other hand, require meticulous assembly, making them suitable for situations where customization is crucial.

2. Cost-effectiveness: Cartridge seals may have a higher upfront cost due to their pre-assembled nature. However, their ease of installation and reduced downtime can offset this, making them more cost-effective in the long run. Component seals, while potentially cheaper initially, may lead to higher associated costs due to longer installation times and maintenance requirements.

3. Standardization vs. Customization: Cartridge seals provide standardized sealing solutions that can be easily replaced, offering consistent performance across multiple applications. Component seals, on the other hand, allow for customization, making them ideal for non-standard or unique equipment requirements.

4. Operating Environment and Conditions: The requirements of the operating environment, such as temperature, pressure, and media, play a crucial role in determining the suitable sealing solution. Cartridge seals generally offer reliable performance in a wide range of conditions, while component seals provide flexibility to withstand extreme or challenging operating conditions.

5. Personnel Skill Level: The complexity of the sealing solution and assembly process is an essential factor. Cartridge seals are designed for ease of use and can be installed by less skilled personnel. Component seals require a higher level of expertise, ensuring proper assembly and alignment for optimal performance.

Conclusion – Making the Right Decision for Your Specific Application

Choosing the right sealing solution between cartridge seals and component seals should be based on a careful evaluation of each application's unique requirements. While cartridge seals provide ease of installation, reliability, and standardization, component seals offer customization, flexibility, and adaptability. By considering factors such as installation/maintenance ease, cost-effectiveness, standardization vs. customization needs, operating conditions, and personnel skill level, engineers and maintenance professionals can make an informed decision to optimize the performance of their equipment and minimize the risk of leaks. Remember, the right sealing solution is crucial for smooth operation, increased efficiency, and prolonged equipment lifespan.