Balancing Cost and Performance with Grundfos Mechanical Seals in Industrial Equipment

Balancing Cost and Performance with Grundfos Mechanical Seals in Industrial Equipment

Introduction

Industrial equipment plays a crucial role in various sectors, including manufacturing, energy production, and wastewater treatment. The efficiency and reliability of these machines heavily depend on the performance and longevity of their components. One such critical component is the mechanical seal, which ensures the proper sealing of rotating shafts in pumps, compressors, and other industrial equipment. It is important to strike a balance between cost and performance when selecting mechanical seals for industrial applications. Grundfos, a renowned global leader in pump manufacturing, offers a range of innovative mechanical seals that excel in both cost-effectiveness and performance. This article explores how Grundfos mechanical seals address the challenges faced in industrial equipment, and how they effectively balance cost and performance.

Understanding the Role of Mechanical Seals

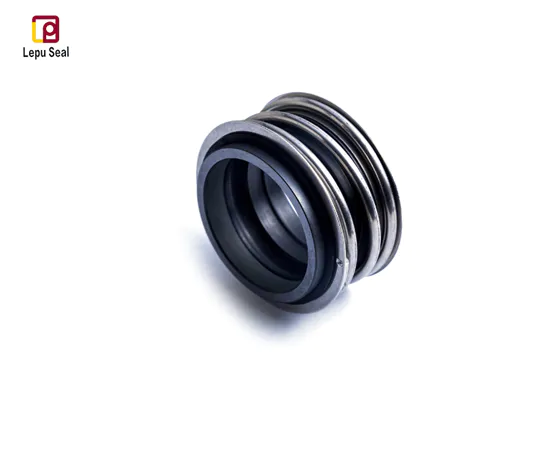

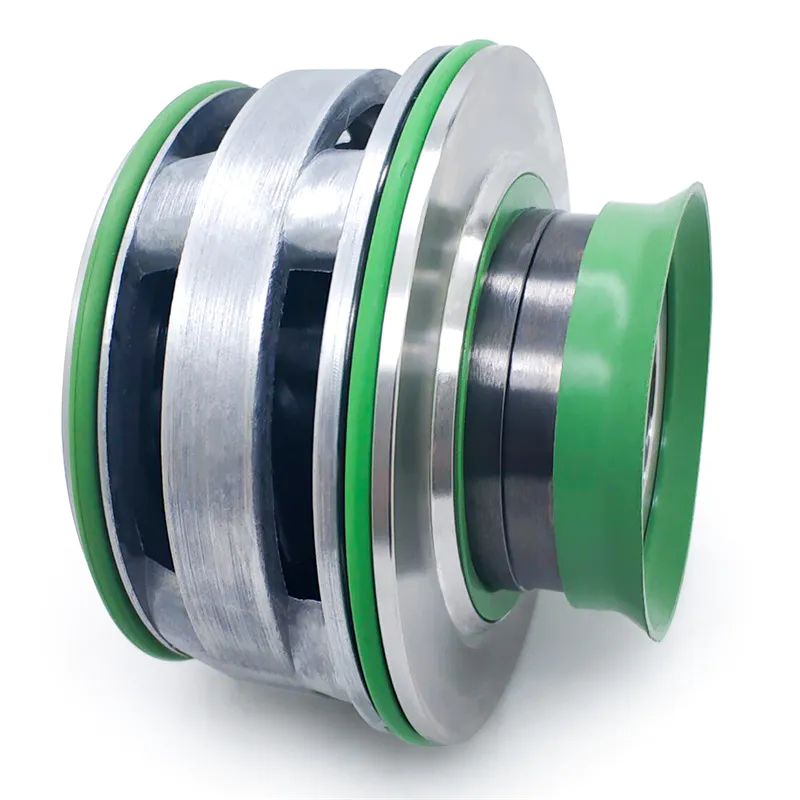

1. Ensuring Reliable Performance: Mechanical seals are primarily responsible for preventing leakage of fluids, such as water, oil, or chemicals, from the pump or equipment. They create a barrier between the rotating shaft and the stationary pump housing, ensuring reliable performance and minimizing the risk of contamination or environmental damage.

The Challenges in Industrial Applications

2. Harsh Operating Conditions: Industrial equipment operates in diverse environments, ranging from extreme temperatures and pressures to the presence of corrosive or abrasive media. Mechanical seals must withstand these challenging conditions without compromising their sealing ability and durability.

3. Cost Constraints: Industrial operations are often cost-sensitive, and companies constantly seek ways to optimize expenses. While it is important to select cost-effective mechanical seals, compromising on quality can result in frequent breakdowns, costly repairs, and downtime, negatively impacting productivity and overall profitability.

Grundfos Mechanical Seals – The Perfect Balance

4. Advanced Design and Material Selection: Grundfos mechanical seals are designed with advanced technologies and innovative materials to meet the stringent demands of modern industrial applications. Their seals possess excellent chemical resistance, capable of withstanding aggressive acids, bases, and solvents, ensuring long-term durability and reliability.

5. Performance Excellence: Grundfos seals undergo rigorous testing to ensure exceptional performance under various operating conditions. They exhibit low-friction characteristics, minimizing energy consumption and enhancing overall efficiency. This not only reduces operational costs but also contributes to a sustainable and environmentally-friendly approach.

6. Easy Installation and Maintenance: Grundfos understands the importance of minimizing downtime in industrial settings. Their mechanical seals are designed for easy installation and maintenance, allowing technicians to quickly replace seals, thus reducing equipment downtime and optimizing productivity.

7. Customized Solutions: Grundfos recognizes that each industrial application is unique, often requiring tailored solutions. By collaborating closely with customers, Grundfos offers customized mechanical seals that fit specific equipment requirements, enabling the perfect balance between cost and performance.

Cost Benefits of Grundfos Mechanical Seals

8. Reduced Total Cost of Ownership: Grundfos mechanical seals provide excellent longevity, minimizing the frequency of replacements and repairs. This ensures a significant reduction in the total cost of ownership, contributing to long-term cost-effectiveness without compromising performance.

9. Increased Equipment Reliability: By choosing Grundfos mechanical seals, industrial equipment operators can enhance the reliability and uptime of their machines. This minimizes the risk of unexpected breakdowns and prolongs equipment life, avoiding costly production interruptions.

Conclusion

In the realm of industrial equipment, the selection of mechanical seals is crucial to achieving the delicate balance between cost and performance. Grundfos mechanical seals have proven their efficacy in addressing the challenges faced in industrial applications. With their advanced design, superior performance, easy installation, and customization options, Grundfos mechanical seals provide a cost-effective solution without compromising on reliability or efficiency. By choosing Grundfos, industrial equipment operators can rest assured that their machines are equipped with the finest mechanical seals, ensuring a balance between cost and performance for a profitable and sustainable operation.