Applications of Single Spring Mechanical Seals in High-Temperature Environments

Introduction

Single spring mechanical seals are crucial components used in various applications, especially in high-temperature environments. These seals are designed to provide reliable sealing solutions, preventing leakage and ensuring the efficient operation of machinery and equipment. By effectively withstanding extreme temperatures, they play a vital role in industries such as petrochemicals, oil and gas, and chemical processing, among others. In this article, we will explore the versatile applications of single spring mechanical seals in high-temperature environments, highlighting their benefits and key features.

The Role of Single Spring Mechanical Seals in High-Temperature Environments

Single spring mechanical seals are specifically engineered to withstand the challenges posed by high temperatures. They play a pivotal role in preventing leaks and maintaining the integrity of equipment operating under extreme conditions. In high-temperature environments, the seals face significant challenges, including thermal expansion, pressure differentials, and chemical aggressiveness. Therefore, the use of these seals is vital to ensure the reliability and efficiency of processes.

The Construction and Working Mechanism of Single Spring Mechanical Seals

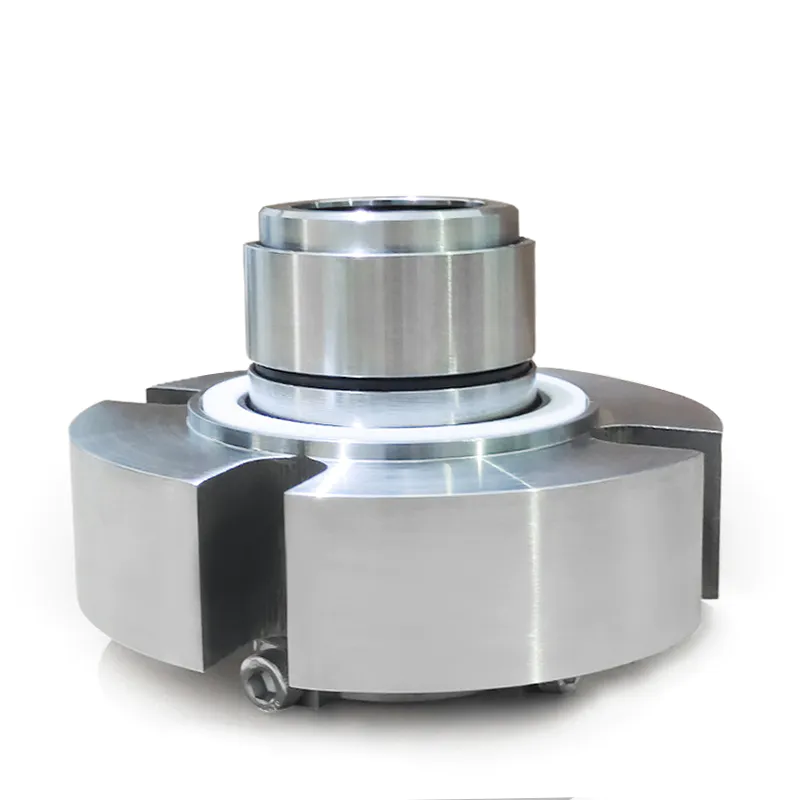

Single spring mechanical seals are designed with utmost precision to withstand high temperatures. They consist of several components, including a stationary seal face, rotating seal face, springs, and metal parts. The stationary seal face is fixed in position, while the rotating seal face rotates with the equipment shaft. The springs provide the required axial force and maintain the face-to-face contact between the stationary and rotating seal faces. This contact ensures effective sealing, even under high temperatures.

When the equipment is operational, the seal faces experience frictional heat due to the rubbing action. Meanwhile, the springs exert a force to prevent any leakage. The combination of the mechanical design and materials used in these seals enables them to withstand the extreme temperatures prevalent in high-temperature environments.

The Benefits of Single Spring Mechanical Seals in High-Temperature Environments

1. Reliable Sealing: Single spring mechanical seals offer excellent sealing performance, even in challenging high-temperature applications. They prevent leakage, ensuring the safety and efficiency of equipment.

2. Cost-Effective Solution: These seals are a cost-effective sealing option for high-temperature environments. They have a long service life, reducing the need for frequent replacements and maintenance.

3. Wide Temperature Range: Single spring mechanical seals are designed to withstand a wide range of temperature fluctuations. They can effectively operate in extreme high-temperature conditions without compromising their sealing performance.

4. Versatility: These seals are suitable for various applications in high-temperature environments, including pumps, mixers, agitators, compressors, and reactors. Their versatility makes them a valuable sealing solution across different industries.

5. Resistance to Chemical Aggressiveness: Single spring mechanical seals are engineered to withstand the corrosive effects of chemicals commonly encountered in high-temperature environments. This resistance ensures the longevity and reliability of the seals.

1. Petrochemical Industry: In the petrochemical industry, single spring mechanical seals find extensive use in pumps, compressors, and agitators. Their ability to withstand high temperatures and resist chemical aggressiveness ensures the safe and efficient processing of petroleum-based products.

Within this industry, these seals are primarily employed in refinery processes, such as crude oil distillation, catalytic cracking, and hydrocracking. The seals ensure the integrity of equipment, preventing leaks that could lead to hazardous incidents or environmental pollution.

2. Oil and Gas Industry: The oil and gas industry involves exploration, production, refining, and transportation of hydrocarbon resources. Single spring mechanical seals play a crucial role in various equipment within this industry. They are extensively used in pumps, compressors, and turbines, which operate in extreme conditions, including high temperatures and pressure differentials.

These seals ensure the safety and efficiency of operations in offshore platforms, refineries, and pipelines. By preventing leakages, they minimize the risk of accidents and ensure the smooth functioning of equipment, avoiding costly downtime.

3. Chemical Processing: In chemical processing plants, single spring mechanical seals are essential for maintaining equipment integrity and preventing leaks while handling corrosive and hazardous chemicals. They are commonly utilized in pumps, mixers, reactors, and agitators.

The chemical processing industry encompasses various sectors, including pharmaceuticals, fertilizers, dyes, and specialty chemicals. In each of these sectors, these seals provide the necessary sealing solutions, allowing for safe and efficient processing of chemicals.

4. Power Generation: Single spring mechanical seals find significant applications in the power generation industry, where they are utilized in turbines, pumps, and compressors. The power generation process often involves high-temperature environments due to the steam or gas used to generate electricity.

In nuclear power plants, these seals play a crucial role in preventing the release of radioactive material, ensuring a high level of safety. In thermal power plants, they help to maintain the integrity of turbines, steam generators, and other equipment, contributing to the efficient generation of electricity.

5. Food and Beverage Industry: Within the food and beverage industry, single spring mechanical seals are utilized in various equipment, including pumps, mixers, and homogenizers. These seals ensure the hygienic processing of food and beverages by preventing contamination and maintaining the integrity of the equipment.

Whether in breweries, dairies, or soft drink production, these seals offer the necessary sealing solutions that meet the stringent requirements of the food and beverage industry. They are designed for easy cleaning and compliance with industry regulations.

Conclusion

Single spring mechanical seals are indispensable components in high-temperature environments, providing reliable sealing solutions for a wide range of industries. Their ability to withstand extreme temperatures, pressure differentials, and aggressive chemicals ensures the safe and efficient operation of equipment. From the petrochemical industry to power generation and food and beverage processing, these seals play a critical role in preventing leaks and maintaining the integrity of machinery. With their cost-effectiveness, versatility, and longevity, single spring mechanical seals continue to be the preferred choice for high-temperature sealing applications.