Advancements in Material Science: Improving Resilience of Single Cartridge Mechanical Seals

Industrial equipment and machinery require efficient sealing solutions to prevent leakage and ensure smooth operation. Single cartridge mechanical seals have emerged as a popular choice for enhancing the performance and reliability of various rotary equipment. These seals play a vital role in preventing leaks between the rotating and stationary parts of machinery, such as pumps and agitators. Advancements in material science have significantly contributed to improving the resilience of single cartridge mechanical seals, enhancing their durability and sealing capabilities.

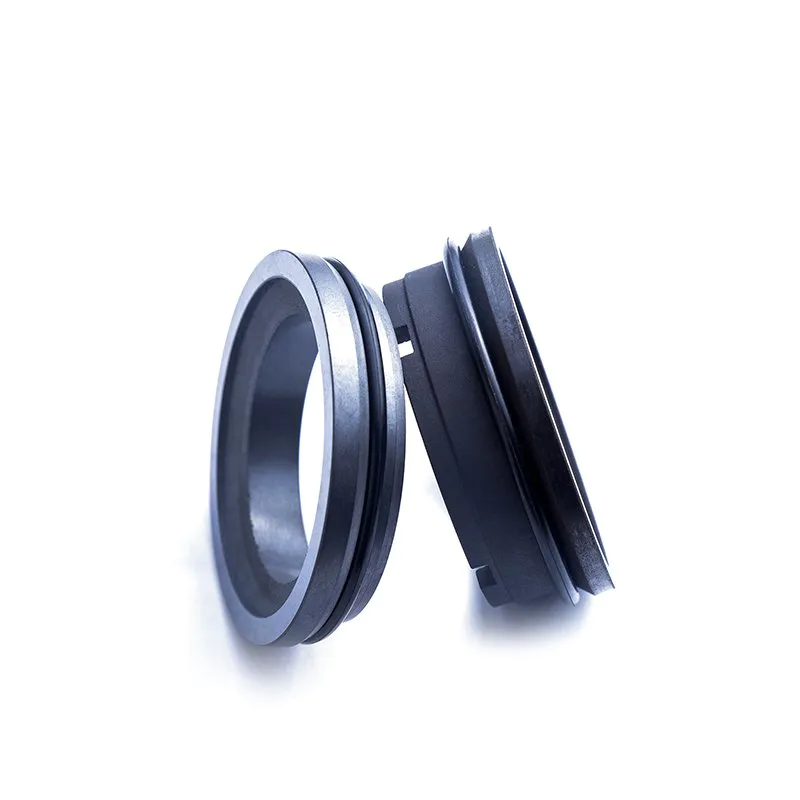

Understanding Single Cartridge Mechanical Seals

Single cartridge mechanical seals are designed to provide a reliable and cost-effective solution for sealing rotating equipment. They consist of two primary components: a rotating seal ring and a stationary seal ring. These rings are held together by a cartridge and compressed against the rotating shaft to effectively prevent fluid leakage. The resilience of these seals is critical to withstand demanding operating conditions, including high temperatures, abrasive fluids, and intense pressures.

The Role of Material Science in Enhancing Resilience

Material science plays a pivotal role in improving the resilience of single cartridge mechanical seals. Researchers continuously explore new materials and develop innovative manufacturing techniques to create seals that offer superior performance and longevity. By choosing the right materials, seal manufacturers can address common challenges such as wear, corrosion, and sealing efficiency, resulting in seals that can withstand harsh operating conditions and extend equipment life.

1. Advanced Polymeric Materials

One of the key advancements in material science is the development of advanced polymeric materials for single cartridge mechanical seals. Traditional materials like carbon and ceramic have been widely used, but advancements in polymer technology offer several advantages. Polymer-based materials exhibit excellent resistance to corrosion and wear, making them ideal for applications where abrasive fluids or chemicals are encountered.

Polytetrafluoroethylene (PTFE) is a commonly used polymeric material in mechanical seals due to its exceptional chemical resistance and low friction properties. PTFE-based materials, such as filled PTFE and reinforced PTFE, have enhanced resilience, reducing wear and improving overall seal performance. In addition to PTFE, other advanced polymer composites, including PEEK (Polyetheretherketone) and PFA (Perfluoroalkoxy), have gained popularity for their excellent mechanical properties and resistance to chemical attack.

2. Innovative Coating Technologies

Coating technologies have revolutionized the resilience of single cartridge mechanical seals. By applying thin layers of special coatings to seal faces and other critical sealing surfaces, manufacturers can greatly enhance the seal's resistance to wear, chemicals, and environmental conditions. These coatings effectively reduce friction and improve the sealing capability of the mechanical seal.

Diamond-like carbon (DLC) coatings are widely employed to improve the resilience of mechanical seals. These coatings offer exceptional hardness, low friction, and excellent resistance to wear. DLC coatings are particularly advantageous in applications involving abrasive fluids or high-speed rotating equipment, as they significantly extend the lifespan of mechanical seals by minimizing wear on sealing surfaces.

3. Nanostructured Materials

The emergence of nanostructured materials has paved the way for significant advancements in the resilience of single cartridge mechanical seals. Nanostructured materials possess unique properties at the nanoscale, making them highly desirable for improving the performance and longevity of mechanical seals. These materials offer enhanced strength, hardness, and resistance to wear and corrosion.

Nano-diamond materials are being extensively researched and utilized in mechanical seals due to their exceptional properties. These materials exhibit high hardness and low friction, making them ideal for applications involving aggressive fluids and high-speed rotating machinery. Their incorporation into single cartridge mechanical seals increases resilience and ensures prolonged service life.

4. Resilient Spring Designs

The design of springs within single cartridge mechanical seals plays a crucial role in their resilience. Springs provide the necessary force to maintain the contact between the seal faces and compensate for any wear or thermal fluctuations that may affect the sealing ability. Advanced spring designs have been developed to enhance the resilience of mechanical seals and ensure consistent sealing performance.

Wave spring designs have gained significant traction in improving the resilience of single cartridge mechanical seals. These springs offer a compact design, reducing the mechanical seal's overall footprint while providing superior load-bearing capabilities. The wave spring's ability to maintain a constant load over a wide range of operating conditions enhances the resilience and sealing performance of mechanical seals.

5. Computational Modeling and Simulation

Computational modeling and simulation have revolutionized the design and development of single cartridge mechanical seals. By utilizing advanced software and algorithms, engineers can accurately predict the performance and resilience of seals under different operating conditions. This enables manufacturers to optimize seal designs, select appropriate materials, and enhance overall seal performance.

Finite Element Analysis (FEA) is widely used in the computational modeling of mechanical seals. FEA simulates the behavior of seals under various loads, temperatures, and fluid conditions, providing valuable insights into their resilience and performance. This information allows engineers to identify potential design flaws, optimize seal geometry, and improve material selection, resulting in highly resilient mechanical seals.

Summary

Advancements in material science have brought significant improvements to the resilience of single cartridge mechanical seals. The incorporation of advanced polymeric materials, innovative coating technologies, nanostructured materials, resilient spring designs, and computational modeling has revolutionized the performance and durability of mechanical seals. These developments contribute to maintaining reliable sealing performance, minimizing downtime, and extending the lifespan of industrial equipment. As material science continues to evolve, the future holds even greater possibilities for enhancing the resilience of single cartridge mechanical seals and driving further advancements in sealing technology.