Advancements in Material Science: Improving Resilience of Metal Bellows Seals

Introduction:

Material science has always played a vital role in advancing technology across various industries. It involves the study and development of materials with enhanced properties that can be utilized in countless applications. In recent years, significant advancements have been made in material science, particularly in improving the resilience of metal bellows seals. These seals are widely used in diverse fields such as aerospace, automotive, oil and gas, and many more. In this article, we will explore the latest developments in material science that have contributed to enhancing the durability and reliability of metal bellows seals.

Understanding Metal Bellows Seals: An Overview

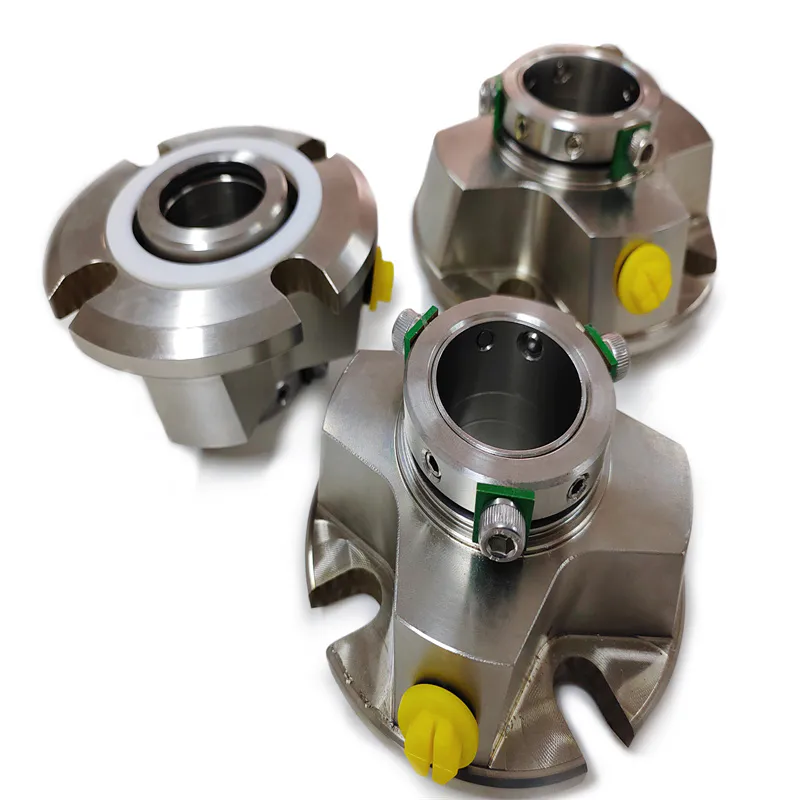

Metal bellows seals are crucial components used for sealing applications. They provide a hermetic seal against gases and liquids, allowing for the containment of pressure or vacuum within systems. These seals consist of a flexible metal bellows with multiple convolutions that can expand and contract in response to changes in pressure, temperature, or axial movement. The flexibility of the bellows enables it to compensate for misalignment, vibration, thermal expansion, and other dynamic factors, ensuring a reliable and leak-free seal.

The traditional material used for manufacturing metal bellows seals is stainless steel due to its excellent mechanical properties, high corrosion resistance, and compatibility with a wide range of operating temperatures. However, certain challenges arise when using stainless steel, such as its limited resilience in extreme conditions and its susceptibility to fatigue failure caused by cyclic loading.

Enhancing Resilience through Composite Materials

To overcome the limitations of stainless steel, researchers have been exploring the use of advanced composite materials in the manufacturing of metal bellows seals. These composite materials combine the strength and stiffness of metallic components with the enhanced properties of non-metallic materials, such as polymers or ceramics.

One promising composite material for metal bellows seals is fiber-reinforced polymer matrix composites. These composites consist of high-strength fibers, such as carbon fibers or glass fibers, embedded in a polymer matrix. The fibers provide the necessary strength and stiffness, while the polymer matrix acts as a protective barrier against corrosion. By carefully selecting the type and orientation of fibers, engineers can tailor the mechanical properties of the composite to meet specific requirements, including resilience to cyclic loading and resistance to chemical degradation.

The use of fiber-reinforced composite materials offers several advantages over traditional stainless steel bellows seals. Firstly, they exhibit a higher fatigue resistance, allowing for prolonged service life even under demanding operating conditions. Secondly, they are inherently lightweight, reducing the overall weight of systems and improving energy efficiency. Lastly, the ability to customize the composite properties enables engineers to optimize the performance of the bellows seal for specific applications, leading to enhanced reliability and reduced maintenance costs.

Nanomaterials: Paving the Way for Superior Seals

Another area of material science that has revolutionized the resilience of metal bellows seals is the development of nanomaterials. Nanomaterials are engineered materials with unique characteristics at the nanoscale, offering exceptional mechanical, electrical, and thermal properties.

One such nanomaterial being explored for metal bellows seals is graphene. Graphene is a single layer of carbon atoms arranged in a honeycomb lattice structure. It possesses extraordinary strength, stiffness, and electrical conductivity, making it an ideal candidate for enhancing the resilience of seals. By incorporating graphene into the bellows' structure, its mechanical properties can be significantly improved, resulting in greater resistance to fatigue failure and increased durability.

Furthermore, researchers are also investigating the introduction of functional nanoparticles, such as nanoparticles of ceramics or self-lubricating materials, into the bellows' surface. These nanoparticles can provide additional benefits, such as enhanced wear resistance and reduced friction, improving the overall performance and longevity of the seals.

Surface Treatments for Enhanced Performance

In addition to exploring advanced materials, surface treatments have also played a crucial role in improving the resilience of metal bellows seals. These treatments involve modifying the surface characteristics of the seal through techniques like coatings, platings, or surface engineering processes.

One widely adopted surface treatment method is the application of diamond-like carbon (DLC) coatings. DLC coatings exhibit excellent hardness, low friction, and high wear resistance, thereby protecting the seal from wear and ensuring smooth operation even under harsh operating conditions. The DLC coatings can be applied to the bellows' outer surface, providing a protective layer against abrasive particles, contaminants, and reducing the risk of corrosion.

Another surface treatment technique gaining attention is laser surface texturing. Laser surface texturing involves creating intricate patterns of micro-dimples or micro-grooves on the seal's surface using laser irradiation. These patterns can improve the lubrication, reduce friction, and enhance the resistance to wear and fatigue. Laser surface texturing can be tailored to specific applications, providing optimized characteristics for different operating conditions, thereby further improving the resilience of metal bellows seals.

Summary

In conclusion, material science has made significant strides in improving the resilience of metal bellows seals. Through the exploration of advanced composite materials, nanomaterials, and surface treatments, engineers have been able to enhance the durability, fatigue resistance, and overall performance of these crucial components. The use of fiber-reinforced composites offers a lightweight and customizable alternative to traditional stainless steel, while graphene and functional nanoparticles open up new possibilities for superior seals. Furthermore, surface treatments like DLC coatings and laser surface texturing provide added protection and improved performance. As material science continues to advance, we can expect even more exciting developments in the field of metal bellows seals, enabling safer and more reliable systems across various industries.