Addressing Seal Leakage Issues in Grundfos Pump Seals: Root Causes and Solutions

Addressing Seal Leakage Issues in Grundfos Pump Seals: Root Causes and Solutions

Introduction

Grundfos pumps are renowned for their reliability and efficiency in various industrial applications. However, one common issue that operators often face is seal leakage. This problem can lead to significant setbacks, including equipment damage, decreased productivity, and increased maintenance costs. In this article, we will explore the root causes behind seal leakage in Grundfos pump seals and delve into effective solutions to address this problem.

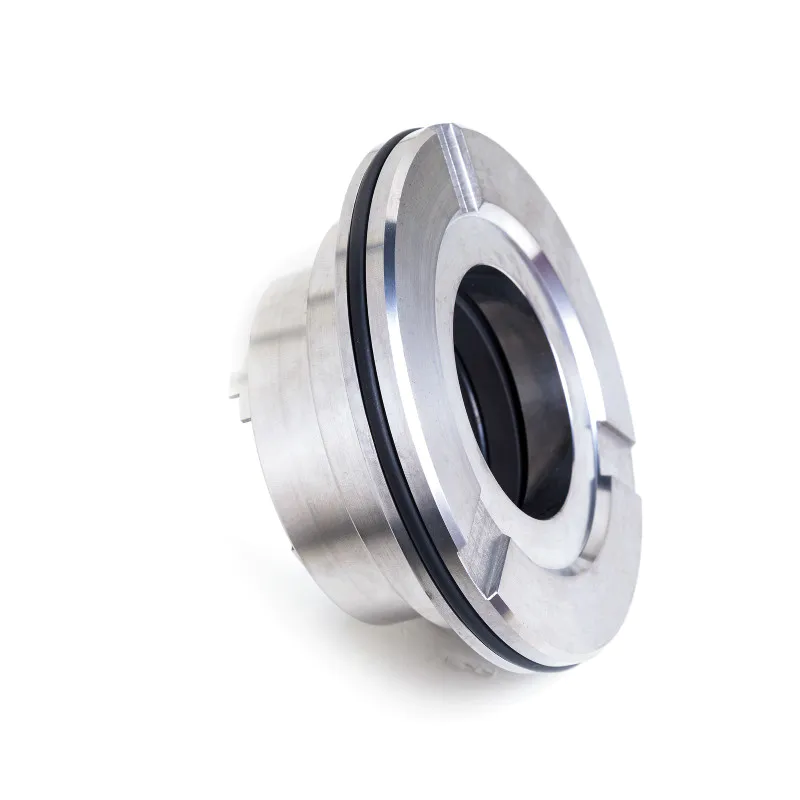

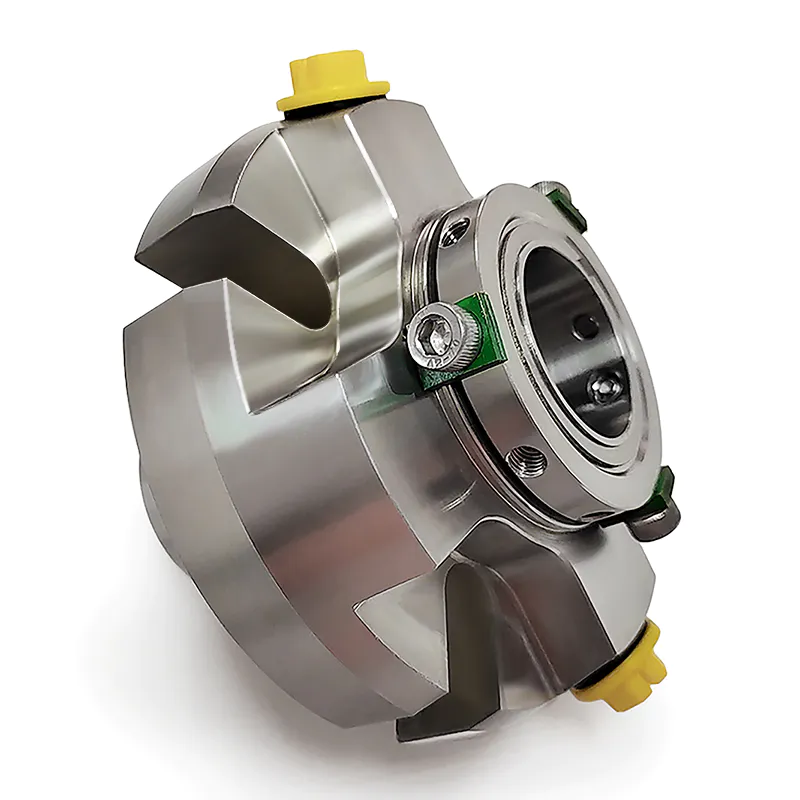

Understanding Pump Seals

Before delving into the causes of seal leakage, it is crucial to understand the role pump seals play in Grundfos pumps. Pump seals are vital components that prevent leakage by creating a barrier between the pump's rotating shaft and the stationary housing. They ensure that the fluid remains contained within the pump and prevent external contaminants from entering. Seal leakage can occur when this barrier is compromised, leading to fluid loss and potential pump failure.

Inadequate Installation Practices

Improper installation is one of the leading causes of seal leakage in Grundfos pumps. When seals are not installed correctly, they may suffer from misalignment, excessive heat, or improper sealing gland load. All these factors contribute to increased wear and tear and eventual leakage. To mitigate this issue, it is essential to adhere strictly to the manufacturer's installation guidelines and ensure that trained personnel handle the installation process.

Seal Material Selection

Choosing the appropriate seal material is crucial to ensure proper sealing and prevent leakage. Different pump applications require different types of seal materials, as each material offers varying resistance to chemicals, heat, and pressure. Using an incorrect seal material that is not compatible with the pumped fluid can lead to seal deterioration and leakage. Proper analysis of the fluid's properties and consulting with manufacturers can aid in selecting the most suitable seal material.

Mechanical Seal Wear

Mechanical seal wear is another significant cause of leakage in Grundfos pumps. Pumps operating under harsh conditions, such as high temperatures, abrasive liquids, or heavy loads, are more prone to seal wear. Over time, seals can become worn, resulting in decreased sealing effectiveness and leakage. Regular monitoring and maintenance of the seal condition are crucial to identify signs of wear and replace seals before they lead to leakage.

Contamination and O-Ring Damage

Contamination of the sealing environment can wreak havoc on the seal's performance. Particles, rust, debris, or even moisture can compromise the sealing surface and promote leakage. Additionally, damage to the O-rings, which provide a crucial sealing function, can also lead to leakage. Implementing effective maintenance practices that focus on cleanliness and regular inspection can help minimize the risk of contamination and O-ring damage.

Insufficient Lubrication

Adequate lubrication is essential to extend the lifespan of pump seals and prevent leakage. Lack of lubrication or using the wrong lubricant can result in increased friction and heat generation, leading to seal degradation and leakage. Regularly monitoring and maintaining proper lubrication levels, as recommended by the manufacturer, can significantly reduce the risk of seal failure.

Conclusion

Addressing seal leakage issues in Grundfos pump seals is vital to ensure the efficient and reliable operation of industrial equipment. By identifying the root causes behind seal leakage, such as improper installation practices, seal material selection, mechanical seal wear, contamination, and insufficient lubrication, operators can take proactive measures to mitigate the risk of leakage. Implementing regular maintenance practices, adhering to manufacturer guidelines, and consulting with experts can go a long way in preventing seal leakage, increasing productivity, and reducing costly downtime.