Understand the selection principle of single-end bellows mechanical seal in one minute

by:Lepu Seal

2022-02-22

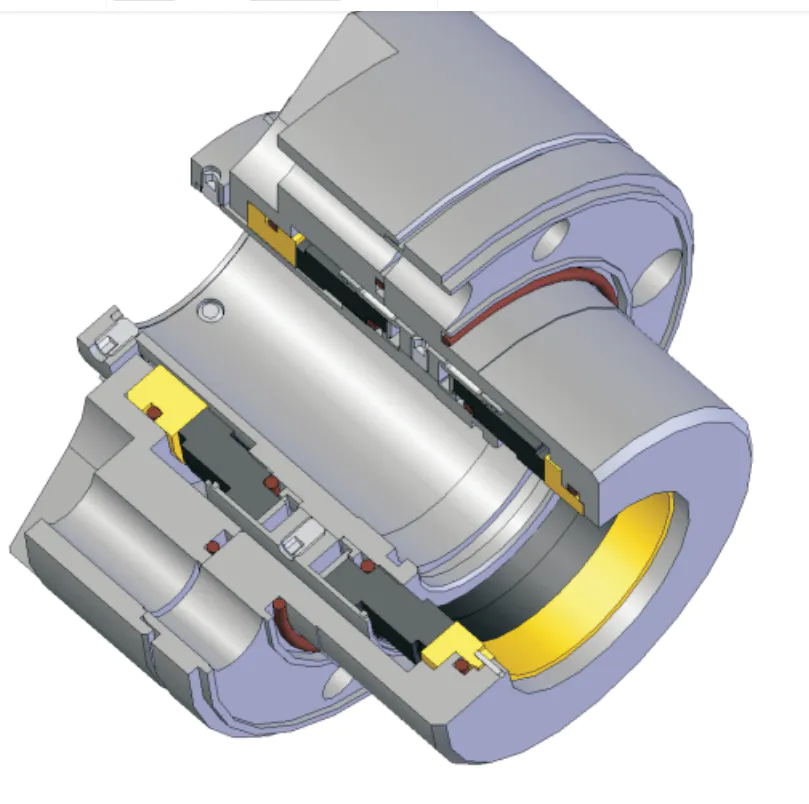

The single-end bellows mechanical seal includes a stationary ring, a rotating ring, a rubber bellows, and a spring assembly. The stationary ring, the rotating ring, the rubber bellows, and the spring assembly are all arranged on the end cover and the pump. Between the shafts, the stationary ring is arranged at the opening of one end cover of the pump shaft, and a stationary ring gasket extending in the circumferential direction is provided at the connection between the outer peripheral surface of the stationary ring and the inner wall of the end cover, The rubber bellows is a T-shaped rubber bellows, there is a groove at the large diameter end of the rubber bellows, the rotating ring is embedded in the groove, and the rotating ring and the rubber bellows form a groove. an accommodating cavity, the accommodating cavity is provided with the spring assembly sleeved on the pump shaft, the two ends of the spring assembly abut on the rotating ring and the rubber bellows respectively, so The rotating ring closely fits and rotates relatively with the stationary ring under the action of the spring assembly. The selection method is based on different working conditions and medium properties, including high temperature and low temperature mechanical seals, high pressure and corrosion resistance mechanical seals, particle medium mechanical seals, and mechanical seals suitable for light hydrocarbon media that are easy to vaporize. Mechanical seals with different structural types and materials are selected for different purposes. The main parameters of the selection are: sealing cavity pressure (MPA), fluid temperature (℃), working speed (M/S), fluid characteristics and effective space for sealing installation. The basic principles of mechanical seal selection are:

1. According to the pressure of the sealing cavity, determine whether the sealing structure is balanced or unbalanced, single-end or double-end, etc.u200bu200b

2. According to the working speed, determine whether to use rotary or static, hydrodynamic or non-contact.u200bu200b

3. According to the temperature and fluid properties, determine the friction pair and auxiliary sealing materials, and correctly select the mechanical seal circulation protection system such as lubrication, flushing, heat preservation, cooling, etc.u200bu200b

4. According to the effective space of the installation seal, it is determined to use multiple springs or single springs or wave springs, built-in or external.

Custom message