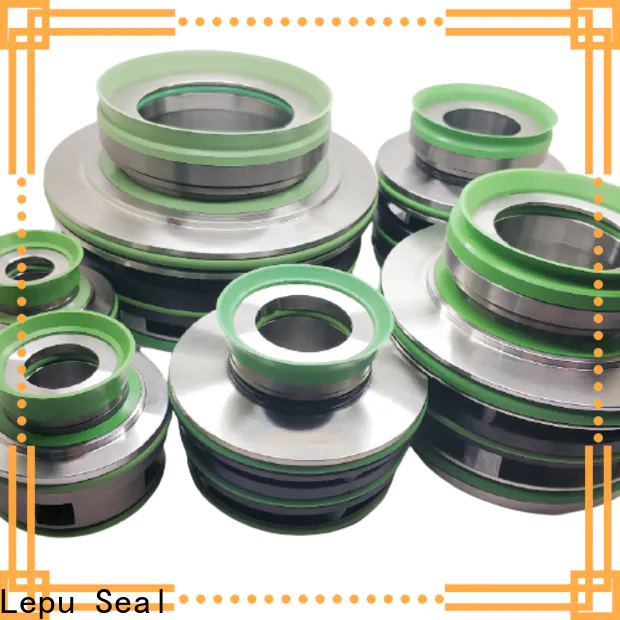

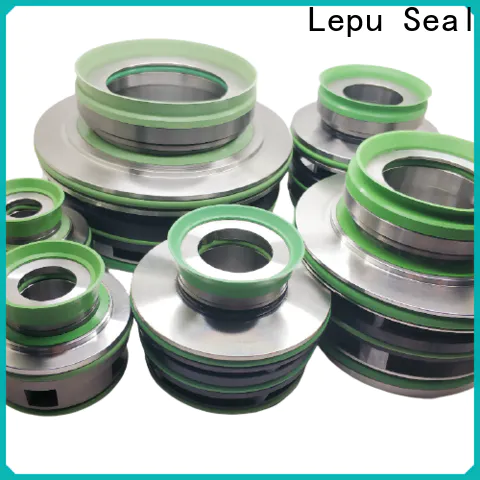

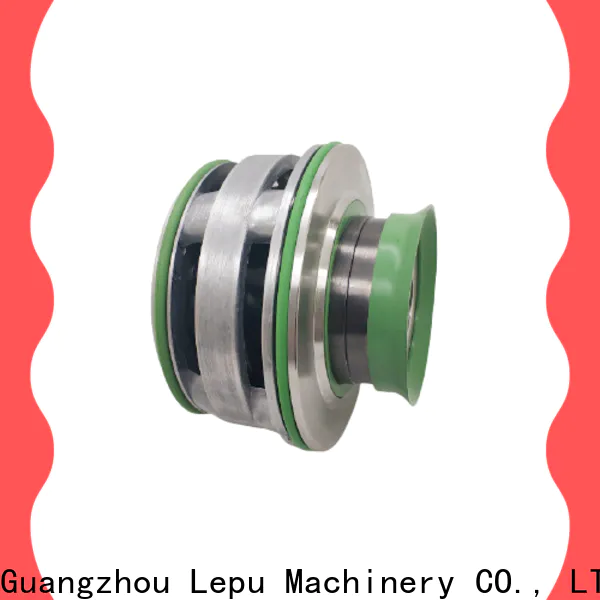

Join hands with famous companies and partners for win-win cooperation.On May 27, Guangzhou Lepu Machinery Co., Ltd. and Guangzhou Xinheng Pump Manufacturing Co., Ltd jointly visited the Yongxin Coal-fired Power Plant in Vietnam to discuss cooperation on related projects. This visit was mainly focused on measuring, repairing pumps and mechanical seals, handling related after-sales issues, and follow-up cooperation.The first phase BOT project of Vinh Tan Coal-fired Power Plant in Vietnam will build 2×620MW Chinese-made supercritical units.The plant is located in Vinh Tan commune, Tuy Phong County, Binh Thuan Province. The plant faces the sea to the south and the site is flat.Vietnam National Highway 1A passes through the north of the plant, and the access road and ash field road are connected to Highway 1A. The power plant uses anthracite from northern Vietnam, and the coal terminal is located to the south of the plant. The circulating cooling water system of the power plant uses seawater for cooling, and its operating fresh water is taken from the Long Song Reservoir. At the same time, a seawater desalination device is set up, and the fresh water required for the operation of the power plant can be prepared by the seawater desalination device when necessary. In addition, the power plant simultaneously builds a denitrification (SCR) device and seawater desulfurization facilities.Guangzhou Lepu Machinery Co., Ltd. was established in 1998. The factory is located in Huangpu District, Guangzhou. It focuses on the production of dry gas seals and mechanical seals and has become a well-known brand in the field of seals in China.Lepu Machinery has a standard modern automated factory, dozens of world-leading CNC machining centers and various advanced processing equipment, as well as professional dry gas seal test systems and containerized mechanical seal test platforms. The engineers in the factory have very rich experience in the design, production and maintenance of dry gas seals and mechanical seals. For 26 years, it has provided high-quality sealing products and services to many domestic and foreign customers, covering many fields such as petroleum, chemical, food, energy, machinery, etc.During this visit, the mechanical seals involved are mainly desulfurization pump seals, boiler feed pump seals and circulating water pump seals.The desulfurization pump mechanical seals, which are used in desulfurization pumps in thermal power plants and play an important role in the desulfurization systems of thermal power plants. To ensure the sealing performance of the pump, prevent the medium in the pump (such as desulfurization liquid) from leaking, and prevent external impurities from entering the pump and affecting the operation. In the application of desulfurization pumps, the mechanical seal of the desulfurization pump has the characteristics of corrosion resistance, wear resistance, reliable sealing performance, design to adapt to different working conditions, and easy maintenance and repair. Such as SE2, HR325.HR325Cartridge Mechanical Seal For Desulfurization PumpHR325Cartridge Mechanical Seal For Desulfurization PumpHR325Cartridge Mechanical Seal For Desulfurization PumpCommon desulfurization pump mechanical seal materials include silicon carbide, cemented carbide, ceramics, etc. The selection needs to be reasonably matched based on specific process parameters and environmental conditions. In addition, regular maintenance is also very important to extend the life of the mechanical seal and ensure the stable operation of the equipment.H75Cartridge Mechanical Seal For Desulfurization PumpH75Cartridge Mechanical Seal For Desulfurization PumpH75Cartridge Mechanical Seal For Desulfurization PumpCirculating water pump seals are usually used in cooling water circulation systems, such as air conditioning systems, cooling towers, cooling cycles in industrial production, etc. It can effectively prevent cooling water or other media from leaking into the external environment to avoid loss and pollution. And under low to medium pressure and temperature conditions, the seal can maintain stable sealing performance.Cartex SNCartridge Mechanical Seal For Circulating Water PumpCartex SNCartridge Mechanical Seal For Circulating Water PumpCartex SNCartridge Mechanical Seal For Circulating Water PumpFinally, we sincerely hope that Lepu and Vietnam Vinh Tan Coal-fired Power Plant can continue the current cooperation concept and jointly embark on a new journey of "strong alliance, win-win situation".

Read More>>

All Products

-

Top Dry Gas Seal Wholesale

-

PUMP & PUMP PARTS Company

-

Buy Dry Gas Seal

- Buy Mechanical Seal Exporter

-

Buy OTHER PRODUCTS Company

-

Customized Dry Gas seal

- Certificated Mechanical Seal

-

SEAL PARTS Wholesale

-

SEAL PARTS For sell

-

Top cartridge seal Supplier

-

Best PRODUCTS

- OTHER BRAND PUMP SEAL Exporter

-

Hot Eagle Burgmann Mechanical Seal Factory

-

Quality Spare Parts For Mechanical Seal Factory

-

Buy John Crane Mechanical Seal Factory

-

Certificated O-ring Mechanical Seals Supplier

- Hot OTHER BRAND PUMP SEAL Warranty

-

Alfa Laval Mechanical Seal Bulk

-

Best AESSEAL MECHANICAL SEAL For sell

-

Hot Eagle Burgmann Mechanical Seal Supplier

-

Hot Grundfos Mechanical Seal Supplier

-

Certificated Flygt Pump Mechanical Seal

-

Customized Grundfos mechanical seal

-

Certificated Rubber & PTFE seal For sell

-

Single spring mechanical seal Bulk

-

Top Seal rings Exporter

-

Best Cartridge mechanical seal Bulk

-

Customized APV mechanical seal

-

AES mechanical seal Bulk

-

Best double mechanical seal

-

Quality auto cooling pump seal

-

Alfa laval mechanical seal Factory

-

Customized pillar mechanical seal Company

-

Mechanical seal for nissin pump Exporter

-

Hot Fristam mechanical seal Manufacturing

-

Certificated John crane mechanical seal Bulk

-

Top Grundfos mechanical seal Manufacturer

-

Flygt mechanical seal Wholesale

-

O ring mechanical seals Manufacturer

-

Elastomer bellow shaft seals Manufacturer

-

Buy Burgmann mechanical seal Wholesale

-

Top Blackmer pump seal Manufacturer

- Buy Bellows seal

-

Quality APV mechanical seal

-

Alfa laval mechanical seal Manufacturer

-

Best AES mechanical seal For sell

-

Grundfos mechanical seal For sell

Hot products