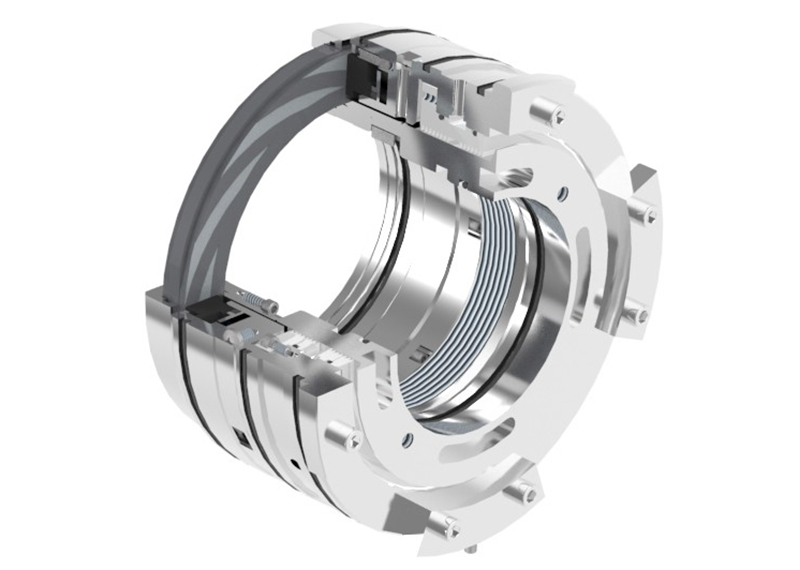

LPDGS-801, A compressor process seals which is designed to seal the rotating assembly in the stationary compressor case to prevent the process gas in the compressor from getting to the atmosphere and to prevent the atmosphere from getting into the process gas.

Centrifugal compressors have seals on the rotating shafts that prevent the high-pressure natural gas from escaping the compressor casing. These seals can be high-pressure oil ("wet”) seals or mechanical gas (“dry”) seals, which act as barriers against escaping gas.

LPDGS-801 dry gas mechanical seal is a special design for centrifugal comrepssors, under normal circumstances, the primary seal bears the full pressure of the medium, and the secondary seal runs under low pressure or normal pressure. When the primary seal fails completely, the secondary seal functions as the main seal, and it can run safely for at least 8 hours.

The secondary seal is injected with buffer gas under pressure, and is isolated by comb seals to prevent the primary leaking medium from contaminating the secondary dry gas seal. The process medium leaked from the primary seal is taken to the torch combustion / collection tank for centralized discharge, safe and environmentally friendly ; The buffer gas under pressure can reduce the vaporization of the medium on the primary seal face, improve the lubrication effect of the mechanical seal, and extend the seal service life.

LPDGS-801 is a special design for centrifugal compressors, in the past years, this dry gas seal running with excellent record, and widely use for toxic and hazardous, flammable and explosive dangerous fluid media. Such as ethylene, propylene, liquefied gas, ammonia, MTBE, butadiene, aromatics, benzene media

Advantages Of Dry Gas seals

● Improved reliability: Dry gas seals have fewer parts than traditional seals, reducing the potential for failure. They also eliminate the risk of seal leakage, which can cause damage to the environment, equipment, and personnel.

● Reduced maintenance costs: Dry gas seals require less maintenance than liquid lubricated seals because they do not require a liquid supply, filtration, or cooling system. This results in lower operating costs and increased efficiency.

● Increased safety: The elimination of the liquid lubricant reduces the risk of fires and explosions. Additionally, dry gas seals are typically designed to detect leaks and prevent catastrophic failures.

● Better performance: Dry gas seals are capable of operating at higher speeds and pressures than traditional seals, resulting in improved equipment performance and increased efficiency.

● Environmentally friendly: Dry gas seals eliminate the need for a liquid lubricant, reducing the potential for environmental contamination. They are also more energy-efficient than traditional seals, reducing greenhouse gas emissions and contributing to a more sustainable future.

Sealing Face: Carbon, SIC,

Sealing Face: Carbon, SIC,

Pressure: 0 ~ 10MPa

Temperature: -104 ~ 260 ℃

Speed: ≤3600r / min

SUITABLE FOR CENTRIFUGAL COMPRESSORS.

Suitable for ethylene, propylene, liquefied gas, ammonia, MTBE, butadiene, aromatics, benzene media, etc.

Guangzhou Lepu machinery CO., LTD becomes one of the leading mechanical seal supplier in south of china, we focus in designing and manufacturing mechanical seal for many kinds of famous brand pumps, our mechanical seal cover many kinds of industry like food, petrol chemical, paper making, sea ship, and so on.

Copyright © 2018 Guangzhou Lepu Machinery CO., LTD. | All Rights Reserved Design by www.lepuseal.com

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.