Understanding the Impact of Tungsten Carbide Seal Rings on Pump Performance

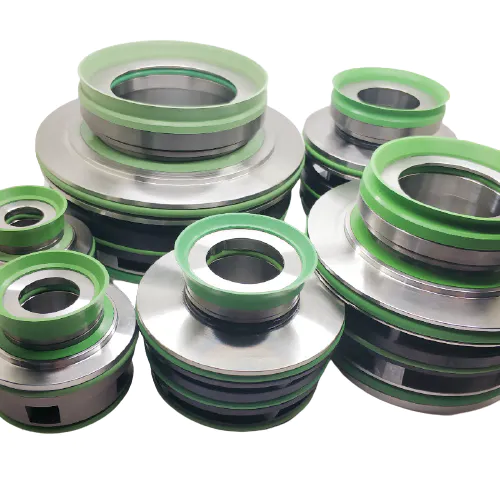

Tungsten Carbide Seal Rings: Enhancing Pump Performance

Introduction

When it comes to fluid handling, pumps play a crucial role in various industries. Whether it is for transferring fluids, maintaining pressure, or controlling flow rates, pump performance is of paramount importance. One of the key components that significantly influence pump efficiency and reliability is the seal rings. Among the various materials used for seal rings, tungsten carbide has gained immense popularity due to its exceptional properties and performance. This article delves into the impact of tungsten carbide seal rings on pump performance, shedding light on the advantages they offer and their application in different pump systems.

The Significance of Seal Rings in Pump Systems

Before we delve into the specific advantages of tungsten carbide seal rings, it is important to understand the significance of these crucial components in pump systems. Seal rings play a vital role in preventing leakage between the rotating shaft and the stationary housing. They act as a barrier, minimizing fluid loss and ensuring the pump operates efficiently. In addition to maintaining fluid integrity, seal rings also help to prolong the lifespan of the pump by reducing wear and tear on the shaft and housing surfaces.

The Exceptional Properties of Tungsten Carbide

Tungsten carbide is a remarkable material known for its exceptional strength, hardness, and resistance to wear. It is a composite material made of tungsten and carbon, and fabricated through a powder metallurgy process. The resulting material exhibits remarkable properties, making it an ideal choice for seal rings in demanding pump applications.

Unparalleled Hardness and Wear Resistance

One of the primary advantages of tungsten carbide seal rings is their unparalleled hardness. Tungsten carbide ranks very high on the Mohs scale, second only to diamond. This remarkable hardness provides superior resistance to wear, enabling the seal rings to withstand the abrasive forces and high pressures commonly encountered in pumps handling aggressive fluids or slurries.

Furthermore, tungsten carbide's excellent wear resistance ensures that the seal rings maintain their shape and dimensional stability over extended periods of operation. This property is particularly critical in applications where abrasive or corrosive media may cause premature wear, compromising pump performance and necessitating frequent maintenance.

Chemical Inertness and Corrosion Resistance

Tungsten carbide seal rings also exhibit excellent chemical inertness and corrosion resistance. They are highly resistant to various chemicals, acids, and alkalis, ensuring the integrity and performance of the pump even when handling corrosive fluids. This resistance to chemical attack prevents the seal rings from deteriorating or undergoing reactions that could lead to leaks or compromised pump performance.

Superior Thermal Stability

Another advantage of tungsten carbide is its remarkable thermal stability. It can withstand extreme temperatures without losing its hardness or mechanical properties. This thermal stability is crucial in pump systems that handle high-temperature fluids or operate in environments subject to significant temperature variations. Tungsten carbide seal rings can maintain their integrity and performance under these challenging conditions, ensuring reliable and efficient pump operation.

Enhanced Sealing Efficiency

Tungsten carbide seal rings offer enhanced sealing efficiency due to their exceptional hardness, wear resistance, and dimensional stability. The combination of these properties allows the seal rings to maintain optimal contact with the shaft, creating a tight seal and preventing fluid leakage. This improved sealing efficiency translates into reduced energy losses, improved pump performance, and lower operating costs.

Moreover, the precise machining capabilities of tungsten carbide enable the production of seal rings with tight dimensional tolerances and smooth surface finishes. This precision ensures optimal alignment and contact between the seal rings and the rotating shaft, further enhancing the sealing efficiency and minimizing fluid bypass.

Applications of Tungsten Carbide Seal Rings

Tungsten carbide seal rings find applications in various pump systems across diverse industries. Their exceptional properties make them suitable for demanding applications and challenging operating conditions. Below are some key applications where tungsten carbide seal rings excel:

1. Oil and Gas Industry

In the oil and gas industry, pumps are employed for a wide range of applications, from drilling and production to refining and transportation. Pumps used in this sector often handle corrosive fluids, abrasive slurries, and high pressures. Tungsten carbide seal rings ensure the reliable and efficient operation of these pumps by providing excellent wear resistance, chemical resistance, and sealing efficiency.

2. Chemical Processing

Chemical processing plants deal with a variety of aggressive chemicals, often at high temperatures and pressures. Pumps used in these applications require robust seal rings that can withstand the harsh chemical environment without compromising pump performance. Tungsten carbide seal rings offer the necessary properties to meet these demanding requirements, ensuring safe and efficient fluid handling.

3. Mining and Mineral Processing

Mining and mineral processing involve the handling of abrasive slurries and corrosive chemicals. Pumps used in these industries require seal rings that can withstand constant exposure to abrasive particles, while also resisting chemical attack. The exceptional hardness, wear resistance, and chemical inertness of tungsten carbide make it an ideal choice for seal rings in mining pumps, minimizing downtime and maintenance costs.

4. Power Generation

Power plants rely on pumps for numerous applications, including boiler feedwater, condensate extraction, and cooling systems. In these critical operations, pump reliability and efficiency are key factors. Tungsten carbide seal rings provide the necessary sealing efficiency and wear resistance to ensure smooth operation, reducing the risk of unplanned downtime and optimizing plant performance.

5. Water and Wastewater Treatment

Pumps used in water and wastewater treatment facilities encounter a variety of fluids, chemicals, and debris. The seal rings in these pumps need to withstand abrasion, corrosion, and fouling to maintain optimal performance. Tungsten carbide seal rings offer the required durability, wear resistance, and chemical inertness to keep water treatment processes running smoothly and efficiently.

Conclusion

Tungsten carbide seal rings have a significant impact on pump performance across various industries. Their exceptional properties, including hardness, wear resistance, chemical inertness, and thermal stability, contribute to enhanced sealing efficiency and prolonged pump life. By minimizing fluid leakage, reducing wear on pump components, and ensuring reliable operation, tungsten carbide seal rings help optimize pump performance, reduce maintenance costs, and improve overall productivity in critical fluid handling applications. So, whether it is oil and gas, chemical processing, mining, power generation, or water treatment, choosing tungsten carbide seal rings is a wise investment for maintaining efficient and reliable pump systems.