Tungsten Carbide vs. Traditional Seal Rings: Advantages for Pump Systems

Introduction:

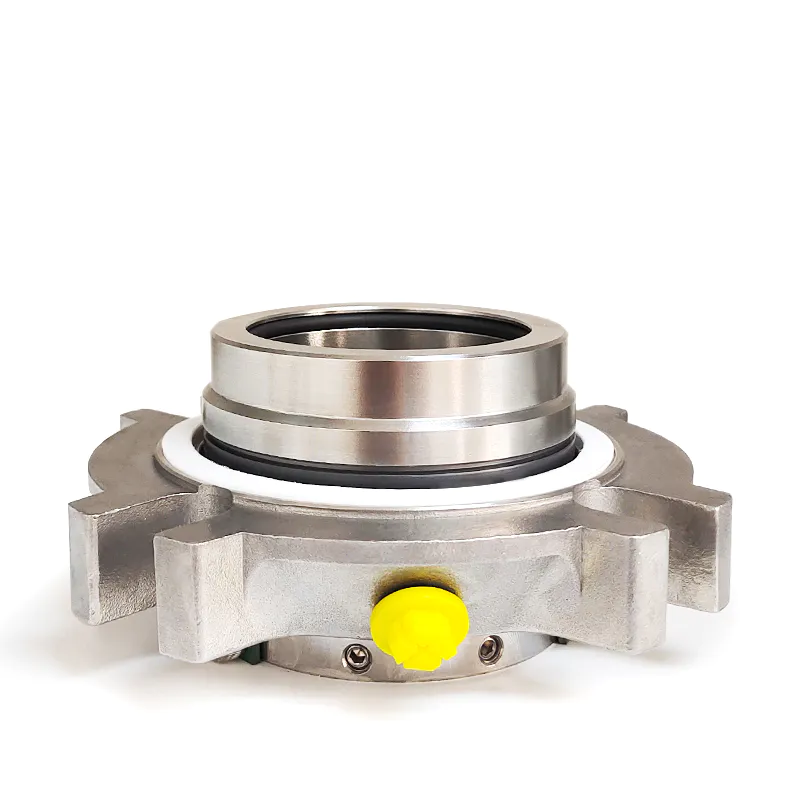

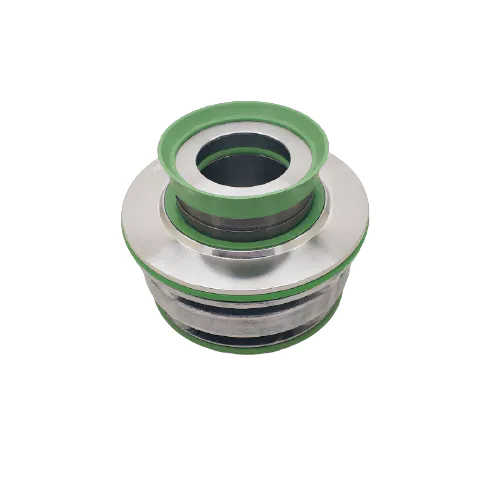

Pump systems are vital components in various industries, including oil and gas, manufacturing, and wastewater treatment. Effective seal rings are crucial for maintaining the integrity and efficiency of these pumping systems. Traditionally, seal rings made from materials like rubber, ceramics, and stainless steel have been used. However, a relatively recent innovation in pump system technology is the use of tungsten carbide seal rings. Tungsten carbide offers several advantages over traditional seal ring materials, making it a popular choice for industries looking to optimize their pump systems. In this article, we will delve into the advantages of tungsten carbide seal rings and how they enhance the performance and longevity of pump systems.

Benefits of Tungsten Carbide Seal Rings:

Tungsten Carbide Seal Rings offer a multitude of benefits that justify their growing popularity among engineers and industries. Let's explore some of these advantages in detail:

Enhanced Wear Resistance and Durability:

One of the key advantages of tungsten carbide seal rings is their exceptional wear resistance. Tungsten carbide is an incredibly hard material, ranking only beneath diamonds in terms of hardness. This remarkable characteristic ensures that tungsten carbide seal rings can withstand high pressures, abrasive materials, and harsh operating conditions without succumbing to wear and tear. Unlike traditional seal ring materials, such as rubber or ceramics, tungsten carbide is highly resistant to scratches and other forms of mechanical erosion. Consequently, pump systems equipped with tungsten carbide seal rings exhibit significantly longer lifespans and reduced downtime.

Superior Chemical Resistance:

Chemical compatibility is essential when selecting seal ring materials, as exposure to corrosive fluids or aggressive chemicals can lead to premature failure of the pump system. Tungsten carbide possesses excellent chemical resistance, allowing it to withstand a wide range of corrosive fluids and abrasive substances. It is particularly effective in environments where the pumped fluids contain acids, alkalis, or abrasive particles. By utilizing tungsten carbide seal rings, industries can mitigate the risk of chemical corrosion, prolonging the lifespan of their pump systems and reducing maintenance costs.

High Thermal Stability:

Temperature fluctuations pose a challenge to the longevity and performance of seal rings. Traditional materials often struggle to maintain their integrity when subjected to high operating temperatures. However, tungsten carbide exhibits exceptional thermal stability, even in extreme conditions. Its ability to withstand high temperatures makes it suitable for pump systems operating in demanding environments, such as chemical processing plants or geothermal power plants. Tungsten carbide seal rings maintain their structural integrity under high thermal loads, ensuring continuous, reliable operation of pump systems.

Excellent Friction and Wear Performance:

Reducing friction and wear between seal rings and rotating shafts is crucial for pump efficiency and performance. Tungsten carbide's low coefficient of friction minimizes energy losses and heat generation during operation. This property translates to improved pump efficiency and reduced power consumption. Additionally, the self-lubricating nature of tungsten carbide contributes to its exceptional wear performance. Unlike other materials that require external lubrication, tungsten carbide seal rings can withstand dry running conditions without compromising their integrity. This feature makes tungsten carbide a particularly attractive choice for pump systems that might encounter periods of low lubrication.

Wide Operating Range:

Pump systems are often used in diverse applications, each with unique operating conditions. Tungsten carbide seal rings offer flexibility and versatility due to their ability to function across a wide range of temperatures, pressures, and speeds. From high-speed centrifugal pumps to slow-speed reciprocating pumps, tungsten carbide can accommodate various pumping system requirements. This adaptability makes tungsten carbide seal rings an excellent choice for industries with diverse operational needs.

Summary:

In conclusion, tungsten carbide seal rings provide numerous advantages over traditional seal ring materials. Their exceptional wear resistance, superior chemical resistance, high thermal stability, excellent friction and wear performance, and wide operating range make them highly desirable for industries reliant on efficient pump systems. By investing in tungsten carbide seal rings, companies can enhance the performance, durability, and longevity of their pump systems, ultimately leading to increased productivity and cost savings. As industries continue to seek innovative solutions to optimize their operations, tungsten carbide seal rings emerge as a reliable and efficient choice for pump systems.