Tungsten Carbide Seal Rings: Overcoming Challenges in High-Pressure Pumping

Introduction

Sealing technology plays a vital role in various industries, especially in high-pressure pumping applications. These applications often face challenges due to intense pressure and abrasive environments. As a result, finding a reliable and robust sealing solution becomes imperative. Tungsten carbide seal rings have emerged as an effective choice for overcoming these challenges. With their exceptional properties and durability, these seal rings have proven to be highly efficient in high-pressure pumping systems. This article explores the various challenges involved in high-pressure pumping and delves into how tungsten carbide seal rings provide an ideal solution.

Understanding High-Pressure Pumping

High-pressure pumping involves the use of powerful pumps to transport fluids or gases at elevated pressures. This process is employed in various industries, including oil and gas, manufacturing, mining, and chemical processing. High-pressure systems are designed to handle extreme operating conditions, ensuring the fluid or gas is effectively transported to the intended destination. However, these systems face several challenges that can impact their performance and longevity.

Challenges Faced in High-Pressure Pumping

1. Extreme Pressure

In high-pressure pumping applications, the systems must withstand extremely high levels of pressure. These pressures can reach several thousand pounds per square inch (PSI) and put immense strain on the sealing components. Conventional sealing materials may fail or deform under such extreme conditions, leading to leakage and system downtime. Tungsten carbide seal rings are specifically engineered to withstand and contain high pressures, making them an excellent choice in these environments.

2. Abrasive Media

Many high-pressure pumping applications involve the transportation of abrasive fluids or gases. These abrasive media can cause significant damage to the sealing components, reducing their effectiveness and lifespan. Traditional sealing materials such as rubber or stainless steel may quickly wear out or corrode, leading to premature failure. Tungsten carbide seal rings exhibit exceptional hardness, wear resistance, and corrosion resistance, making them highly suitable for handling abrasive media efficiently.

3. Temperature Variations

High-pressure pumping systems often operate under conditions where temperature variations are considerable. Fluctuations in temperature can impact the dimensional stability of sealing components, resulting in leakage or system malfunctions. Tungsten carbide seal rings offer excellent thermal stability, enabling them to maintain their shape and sealing integrity even in extreme temperature environments. This property ensures that the pumping systems can operate reliably and efficiently, irrespective of temperature variations.

4. Chemical Compatibility

In industries such as chemical processing, high-pressure pumping systems frequently come into contact with aggressive chemicals. The compatibility of the sealing materials with these chemicals becomes crucial to prevent leakage or material degradation. Tungsten carbide seal rings possess excellent chemical resistance, allowing them to withstand exposure to various corrosive substances. This chemical compatibility ensures the longevity and reliability of the sealing components, minimizing the risk of system failures.

5. Dynamic Pressure Loads

High-pressure pumping systems often experience dynamic pressure loads due to the nature of their operations. These dynamic loads can include pressure spikes, vibrations, or water hammer effects, placing additional stress on the sealing components. Tungsten carbide seal rings are designed to handle such dynamic pressure loads effectively. Their robust construction and high tensile strength allow them to withstand the impact and maintain a secure seal, ensuring the uninterrupted operation of the pumping system.

The Role of Tungsten Carbide Seal Rings

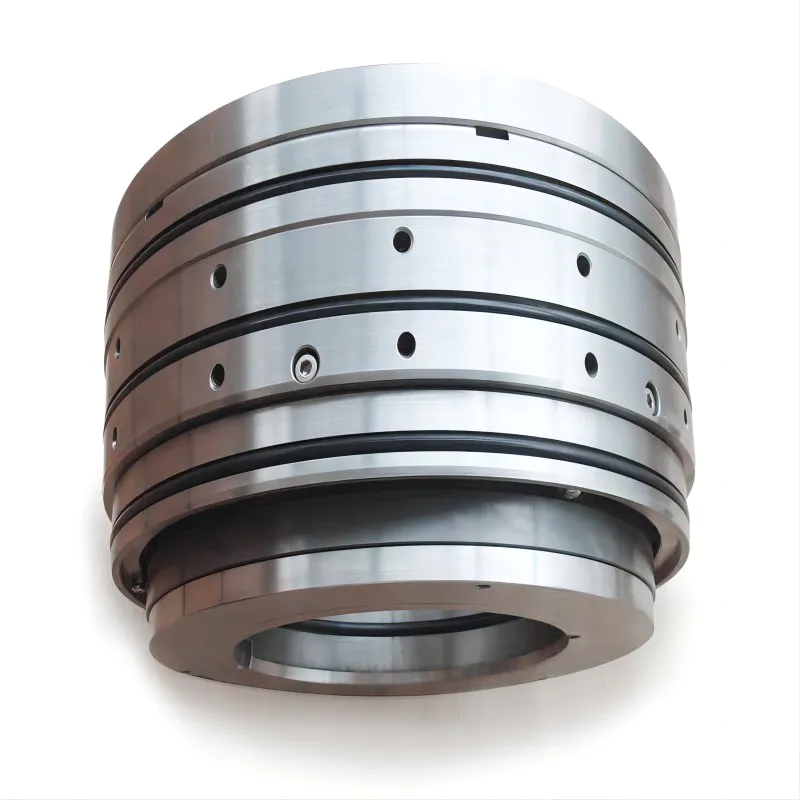

Tungsten carbide seal rings have emerged as a reliable and efficient solution for the challenges encountered in high-pressure pumping applications. These seal rings are typically designed with a combination of tungsten carbide, a compound known for its exceptional hardness, and a binder metal like cobalt. The resulting material exhibits superior wear resistance, high strength, and excellent dimensional stability.

One key advantage of using tungsten carbide seal rings is their ability to withstand extreme pressure. The hardness of tungsten carbide allows it to resist deformation even under immense pressure, providing a reliable sealing mechanism. This property ensures that the pumping systems can maintain their efficiency and avoid costly downtime resulting from seal failures.

Furthermore, tungsten carbide seal rings offer exceptional resistance to abrasive media encountered in high-pressure pumping applications. Their hardness prevents wear and damage caused by abrasive particles, extending the lifespan of the sealing components and reducing maintenance requirements. Additionally, the corrosion resistance of tungsten carbide enables it to withstand exposure to corrosive fluids or gases, making it a highly durable option for challenging environments.

Another significant advantage of tungsten carbide seal rings is their ability to handle temperature variations. Their excellent thermal stability allows them to maintain their sealing integrity, even in extreme temperature conditions. This property ensures that the sealing system remains effective, regardless of the operating temperature, thus preventing leakage and system malfunctions.

Moreover, the chemical compatibility of tungsten carbide seal rings makes them suitable for high-pressure pumping applications involving aggressive chemicals. These seal rings can withstand exposure to various corrosive substances and maintain their performance over an extended period. This resistance to chemical attack enhances the reliability and longevity of the sealing system, minimizing the risk of costly failures.

In addition to their inherent properties, tungsten carbide seal rings are specifically engineered to handle dynamic pressure loads. Whether it is pressure spikes, vibrations, or water hammer effects, these seal rings can effectively withstand the impact and maintain a secure seal. This capability ensures the stability and uninterrupted operation of the high-pressure pumping system, even under varying dynamic conditions.

Conclusion

High-pressure pumping applications necessitate robust sealing solutions to overcome the challenges posed by extreme pressure, abrasive media, temperature variations, chemical compatibility, and dynamic pressure loads. Tungsten carbide seal rings offer a reliable and efficient solution, meeting these requirements with their exceptional properties and durability. Their ability to withstand extreme pressure, resist wear and corrosion, maintain sealing integrity at varying temperatures, and handle dynamic loads makes them an ideal choice for high-pressure pumping systems. By incorporating tungsten carbide seal rings, industries can enhance the reliability, efficiency, and longevity of their high-pressure pumping operations.