The Role of Pillar Mechanical Seals in Pump Systems

Understanding the Importance of Mechanical Seals in Pump Systems

Introduction:

Mechanical seals play a crucial role in pump systems, ensuring the efficient and reliable operation of various industrial processes. One type of mechanical seal, known as pillar mechanical seals, offers unique advantages in terms of sealing performance and longevity. In this article, we will delve into the significance of pillar mechanical seals in pump systems, exploring their functionalities, benefits, and applications.

The Working Principle of Pillar Mechanical Seals

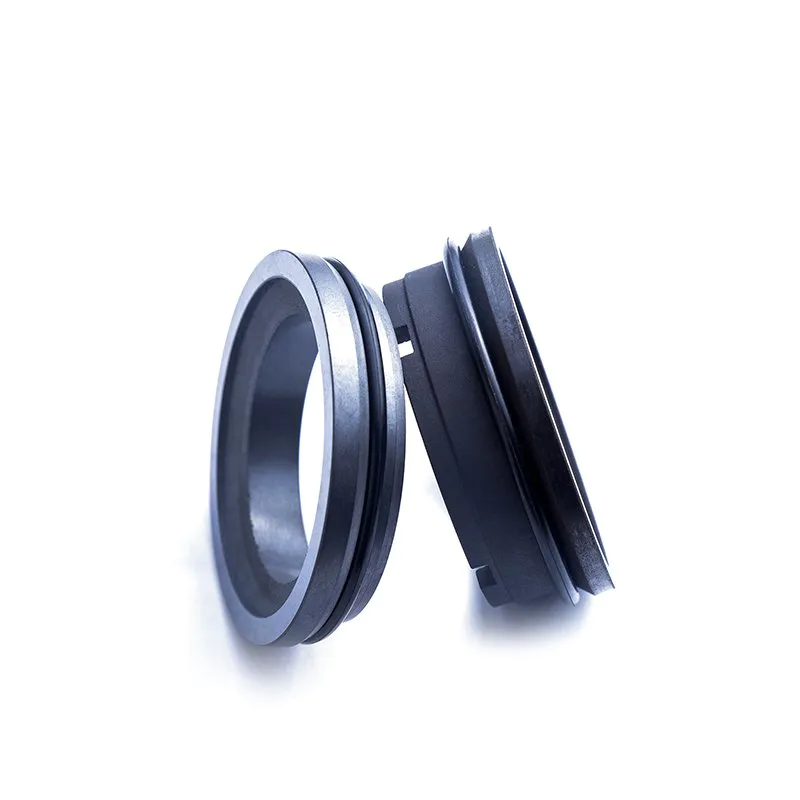

Pillar mechanical seals are designed to provide an effective sealing barrier between the rotating shaft and the stationary housing in a pump system. Their main function is to prevent the leakage of fluids or gases from the pump, ensuring optimal performance and preventing environmental contamination.

These seals consist of several essential components, including a stationary seat, a rotating face, and a set of springs or bellows. The stationary seat is machined into the pump housing, while the rotating face is attached to the pump shaft. The springs or bellows help maintain the necessary contact pressure between the two seal faces, creating a tight seal.

Advantages of Pillar Mechanical Seals

Pillar mechanical seals offer significant advantages over traditional sealing methods, making them a popular choice in many pump systems. Some of the key benefits include:

1. Enhanced Sealing Performance: Pillar mechanical seals are specifically engineered to provide excellent sealing performance under various operating conditions. The tight seal they create minimizes leakage, thus maximizing pump efficiency.

2. Increased Reliability: These seals are designed to withstand prolonged and demanding operation. Their robust construction and materials ensure long-term reliability, reducing downtime and maintenance costs.

3. Reduced Environmental Impact: By preventing fluid and gas leaks, pillar mechanical seals contribute to environmental sustainability by minimizing the release of toxic or hazardous substances into the surroundings.

4. Versatility: Pillar mechanical seals can be applied in various pump systems across multiple industries, including chemical processing, oil and gas, water treatment, and more. Their versatility makes them a valuable sealing solution for a wide range of applications.

Installation and Maintenance Best Practices

Proper installation and ongoing maintenance are crucial for ensuring the optimal performance and durability of pillar mechanical seals. Here are some recommended best practices:

1. Thorough Inspection: Before installing a new seal or conducting maintenance, it is essential to inspect all the components for any signs of damage or wear. Any worn-out parts should be replaced to avoid potential failures.

2. Correct Seal Selection: Choosing the appropriate pillar mechanical seal for a specific pump system is crucial. Factors such as operating temperature, pressure, and media compatibility should be carefully considered to select a suitable seal that meets the system's requirements.

3. Precise Installation: The installation process should be performed by qualified technicians to ensure proper alignment, correct spring compression, and appropriate torque values. Incorrect installation can lead to seal failure and potential damage to the pump.

4. Regular Maintenance: Regular inspection and maintenance are essential to identify any early signs of leakage or performance degradation. Seals should be monitored for wear, and lubrication should be regularly checked and replenished.

Conclusion

In conclusion, pillar mechanical seals play a critical role in pump systems, providing effective sealing performance, reliability, and environmental protection. Their unique design and advantages make them a preferred choice for numerous industrial applications. Proper installation and maintenance are key factors in optimizing their performance and extending their lifespan. By understanding the importance of pillar mechanical seals, industries can ensure the efficient and safe operation of their pump systems.