The Role of Dry Gas Seals in Enhancing Environmental Compliance and Safety

The Role of Dry Gas Seals in Enhancing Environmental Compliance and Safety

Introduction

Dry gas seals have gained significant importance in various industries due to their ability to enhance environmental compliance and safety measures. These seals offer a reliable and efficient way to prevent gas leakage, reduce emissions, and mitigate safety risks. This article delves into the crucial role dry gas seals play in promoting environmental sustainability and ensuring a safe working environment. By exploring their applications, benefits, and maintenance, readers will gain insights into how these seals contribute to enhancing compliance and safety.

What Are Dry Gas Seals?

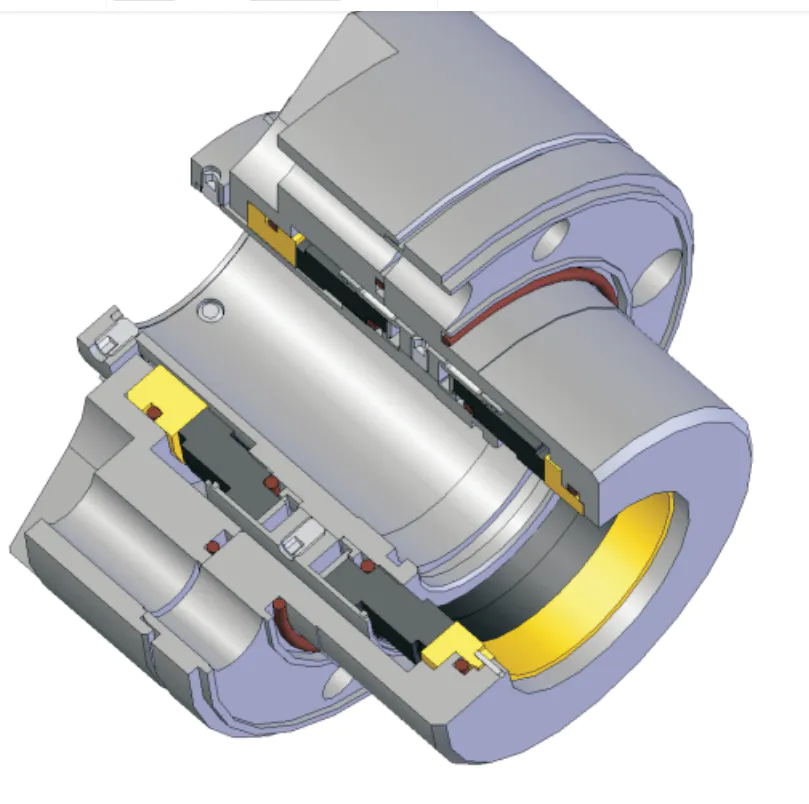

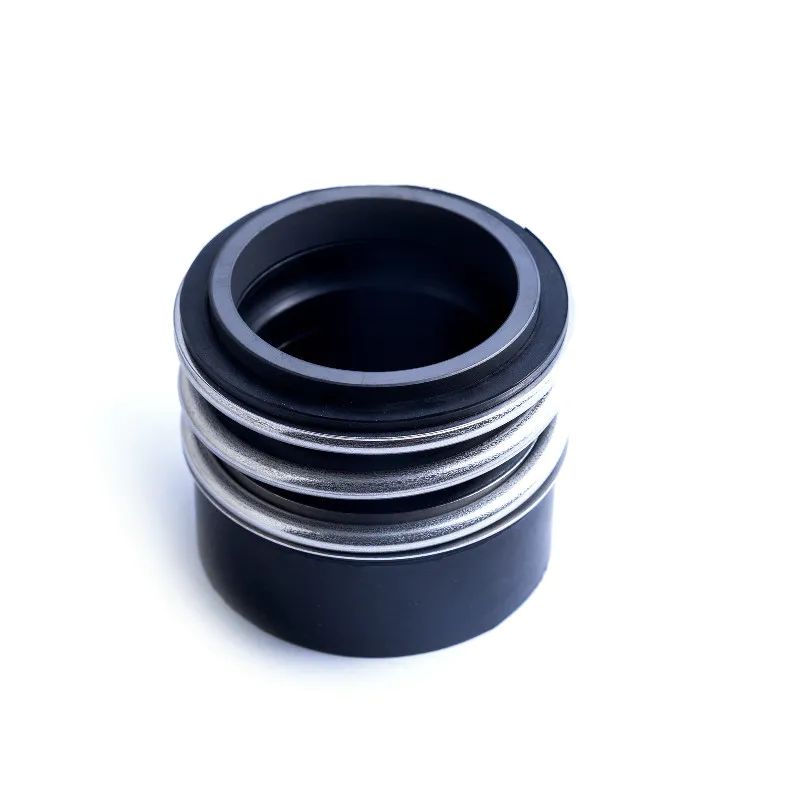

Dry gas seals are specially designed components that prevent leakage of process gases in rotating machinery, such as compressors, pumps, and turbines. Unlike traditional oil-based seals, dry gas seals utilize a seal gas, usually nitrogen, that creates a barrier between the process gas and the environment. This innovative technology eliminates the need for buffer fluids while improving safety, efficiency, and compliance with environmental regulations.

Applications in Various Industries

Dry gas seals find applications in a wide range of industries, including oil and gas, petrochemicals, power generation, and even food and beverage. In the oil and gas sector, these seals are extensively used in compressors for natural gas processing, liquefied natural gas (LNG) facilities, and offshore platforms. Petrochemical plants depend on dry gas seals to ensure the integrity of their rotating equipment, such as ethylene and propylene compressors. Additionally, power generation facilities utilize these seals in steam turbines and gas turbines to minimize environmental impact and comply with stringent emissions regulations.

Benefits of Dry Gas Seals

1. Enhanced Safety: Safety is a paramount concern in any industry. Dry gas seals provide a higher level of safety by preventing the leakage of hazardous gases. This reduces the risk of accidents, fires, and explosions, ensuring the well-being of employees and protecting valuable equipment.

2. Environmental Compliance: In today's era of increasing environmental regulations, companies strive to reduce their carbon footprint and minimize emissions. Dry gas seals greatly contribute to environmental compliance by preventing gas leakage and minimizing fugitive emissions. This not only helps meet regulatory requirements but also shows a commitment to sustainability and responsible operations.

3. Improved Efficiency: Traditional oil-based seals require complex and costly maintenance, leading to downtime. Dry gas seals, on the other hand, offer superior reliability and require less maintenance, resulting in increased equipment uptime and improved productivity. This increased efficiency translates into cost savings for companies in terms of reduced maintenance and improved operational performance.

4. Decreased Product Loss: Leakage of valuable process gases can result in significant economic losses for industries. Dry gas seals effectively eliminate product loss by providing an effective barrier between the process gas and the external environment. This ensures that valuable gases are contained within the system, preventing financial losses and maintaining the overall profitability of operations.

5. Longevity and Reliability: Dry gas seals are designed for longevity and reliability. With proper installation and maintenance, these seals can last for several years, providing a stable and consistent sealing solution. Their ability to withstand extreme conditions, such as high pressures and temperatures, makes them an ideal choice for demanding industrial applications.

Maintenance of Dry Gas Seals

To ensure the longevity and efficiency of dry gas seals, proper maintenance is vital. Regular inspection and preventive maintenance practices should be implemented to identify and address any potential issues. Some key maintenance activities include:

1. Seal Gas System Checks: Regularly inspecting the seal gas system, including pressure regulators, filters, and coolers, helps maintain proper seal gas supply and quality. Clean filters and coolers ensure optimal performance, preventing any unwanted downtime or failures.

2. Monitoring Gas Leakage: Periodically monitoring gas leakage rates allows for early identification of seal deterioration or potential failures. Establishing baseline leakage levels and regularly comparing them helps detect any abnormalities and facilitates timely maintenance or replacement.

3. Cleaning and Venting: Ensuring the dry gas seals are kept clean is essential for optimal performance. Dust, debris, and contaminants should be removed periodically to avoid obstruction and ensure efficient operation. Proper venting procedures should also be followed to prevent gas accumulation in seal cavities, which can lead to damage or malfunction.

4. Bearing and Alignment Checks: Simultaneously checking the condition of bearings and alignment of rotating equipment during dry gas seal maintenance will help identify any issues that may affect overall seal performance. Correcting misalignments and addressing bearing abnormalities will help prolong seal life and prevent costly breakdowns.

Conclusion

Dry gas seals play a vital role in enhancing environmental compliance and safety across various industries. By preventing gas leakage, reducing emissions, and improving operational efficiency, these seals contribute significantly to sustainable and responsible practices. Their ability to ensure a safe working environment, prevent product loss, and minimize downtime showcases their value in enhancing compliance and safety measures. With consistent maintenance practices, dry gas seals can continue to offer reliable sealing solutions, ensuring a greener and safer future for industries worldwide.