The Future of Sealing Technology: Innovations in Double Cartridge Mechanical Seals

Innovations in Double Cartridge Mechanical Seals: Revolutionizing Sealing Technology

Introduction:

Mechanical seals play a pivotal role in preventing fluid leakage in a variety of industrial applications, offering superior sealing performance compared to traditional gland packing. As technology continues to evolve, the double cartridge mechanical seal has emerged as a groundbreaking solution for industries seeking enhanced reliability and efficiency. This article explores the future of sealing technology, focusing on the innovative advancements in double cartridge mechanical seals.

I. Understanding the Basics of Double Cartridge Mechanical Seals:

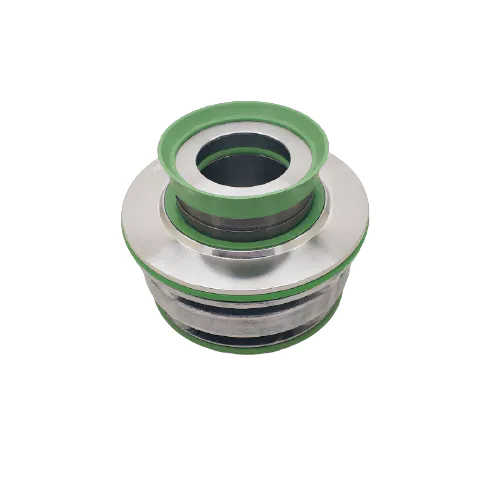

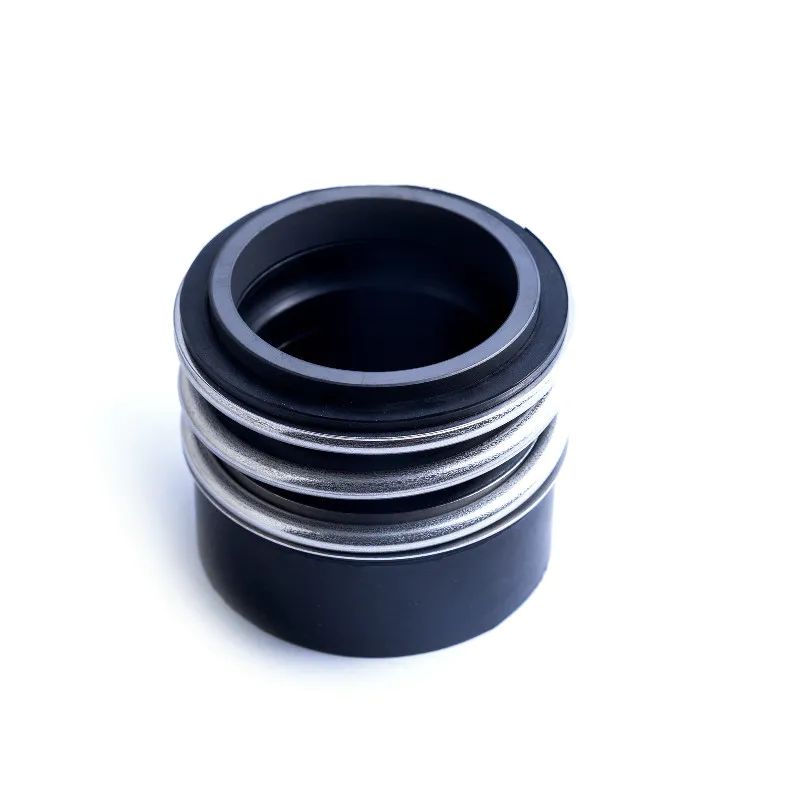

Double cartridge mechanical seals comprise two identical seal faces, mounted back-to-back in separate seal chambers. These seals are designed to create a high-integrity barrier, preventing any potential leakage. The integration of two independent seals ensures maximum safety and efficiency, making them ideal for critical applications where failure can have severe consequences.

II. Enhanced Sealing Performance:

1. Improved Seal Face Design:

With continuous research and development, double cartridge mechanical seals have embraced novel seal face designs that offer superior sealing performance. These designs include diamond-coated seal faces, which provide enhanced wear resistance, reduced friction, and improved heat dissipation. Additionally, innovative groove patterns and surface textures help to optimize fluid flow and minimize the risk of clogging or contamination.

2. Advanced Elastomer Materials:

The advent of advanced elastomer materials has significantly contributed to the improved performance of double cartridge mechanical seals. These materials offer exceptional chemical resistance, high-temperature tolerance, and extended durability, ensuring a longer service life for the seals. The enhanced resilience of elastomers also enables the seals to maintain their sealing integrity under extreme operating conditions.

III. Application Versatility:

1. Process Industry Applications:

Double cartridge mechanical seals find extensive application in the process industry, particularly in the oil and gas, chemical, and pharmaceutical sectors. These seals are engineered to withstand harsh operating conditions, including high pressures, temperature extremes, and corrosive fluids. The inherent versatility of double cartridge mechanical seals makes them an ideal choice for a wide range of process applications.

2. Pumping Systems:

Pumping systems play a crucial role in various industries, and the reliability of these systems heavily relies on the performance of mechanical seals. Double cartridge mechanical seals are increasingly being integrated into pumping systems due to their ability to handle high-pressure and high-speed applications. Their robust design ensures uninterrupted operation, significantly reducing downtime and associated maintenance costs.

IV. Seal Monitoring and Condition-based Maintenance:

1. Integrated Sensor Technology:

In line with the growing demand for the Internet of Things (IoT) solutions, double cartridge mechanical seals are now equipped with integrated sensor technology. These sensors collect real-time data on seal performance, such as temperature, pressure, and vibration. The gathered information assists in identifying potential seal failures, allowing for proactive maintenance and reducing the risk of unexpected downtime.

2. Remote Monitoring Systems:

Advancements in connectivity have given rise to remote monitoring systems for double cartridge mechanical seals. Plant operators can now access real-time seal data remotely, facilitating predictive maintenance strategies. By leveraging artificial intelligence and machine learning algorithms, these systems can accurately predict seal failures, enabling planned maintenance activities and optimizing overall system reliability.

V. Environmental Sustainability:

1. Leakage Reduction and Emission Control:

One significant advantage of double cartridge mechanical seals is their ability to minimize fluid leakage. By maintaining a tight seal, these advanced devices prevent toxic or hazardous fluids from polluting the environment. Additionally, the reduction in leakage contributes to improved energy efficiency by lowering pump loads and decreasing energy consumption.

2. Use of Eco-friendly Materials:

The future of sealing technology lies in promoting environmental sustainability. Double cartridge mechanical seals are increasingly manufactured using eco-friendly materials, such as recyclable plastics and bio-based elastomers. These materials not only offer excellent sealing properties but also minimize the carbon footprint associated with traditional seal manufacturing.

Conclusion:

The future of sealing technology undoubtedly lies in the evolution of double cartridge mechanical seals. With their improved sealing performance, application versatility, advanced monitoring capabilities, and commitment to environmental sustainability, these seals are poised to revolutionize industrial sealing systems. As industries continue to demand higher reliability, efficiency, and reduced environmental impact, double cartridge mechanical seals will play a critical role in meeting these evolving needs.