Single Cartridge Mechanical Seals: A Comprehensive Guide

Single Cartridge Mechanical Seals: A Comprehensive Guide

Introduction:

Mechanical seals are widely used in various industries to prevent leakage and control fluid flow in pumps and other rotating equipment. Among the different types of mechanical seals available, single cartridge mechanical seals are a popular choice due to their simplicity, reliability, and ease of installation. In this comprehensive guide, we will explore the features, advantages, applications, and maintenance tips for single cartridge mechanical seals.

I. Understanding Single Cartridge Mechanical Seals

A. Definition and Working Principle:

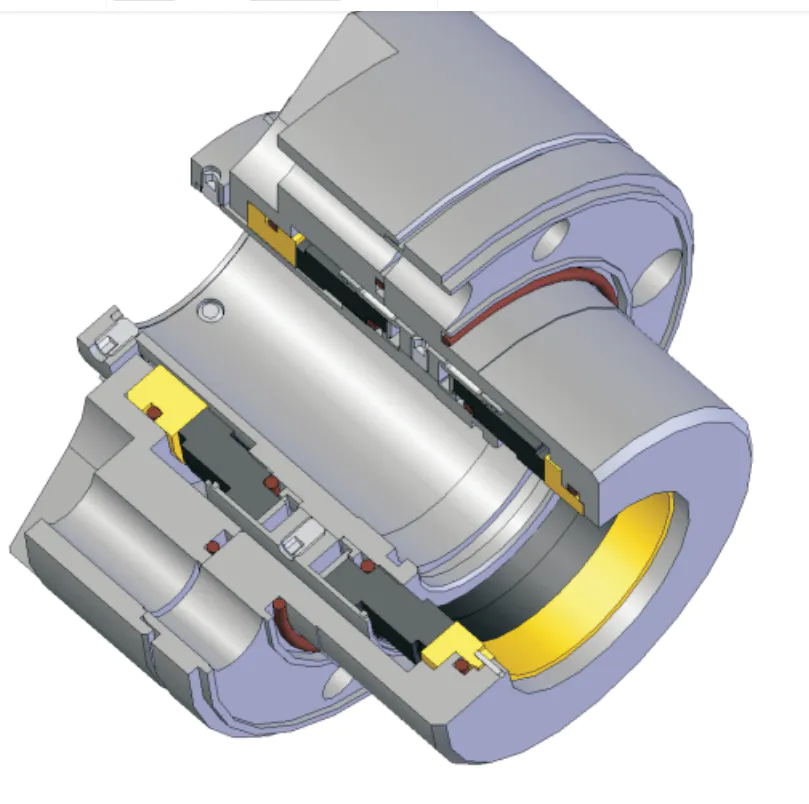

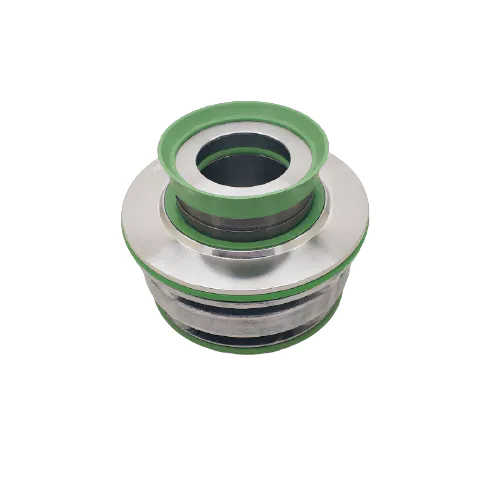

A single cartridge mechanical seal is a self-contained seal unit that consists of a rotating seal face, a stationary seal face, and a gland plate. These components are housed in a single cartridge, making installation and maintenance hassle-free. The seal faces are in constant contact, creating a barrier to prevent fluid leakage.

B. Types of Single Cartridge Mechanical Seals:

There are several types of single cartridge mechanical seals, including pusher type, non-pusher type, and balanced type. Pusher type seals utilize springs to maintain the contact pressure between the seal faces. Non-pusher type seals rely on the fluid pressure to achieve face contact. Balanced type seals are designed to counteract high pressures and provide enhanced durability.

II. Advantages of Single Cartridge Mechanical Seals

A. Easy Installation:

The self-contained nature of single cartridge mechanical seals simplifies the installation process. Since all components are pre-assembled and aligned, installation time is significantly reduced.

B. Reduced Downtime:

In case of seal failure, replacing a single cartridge mechanical seal is quick and straightforward. This minimizes equipment downtime, leading to increased productivity.

C. Enhanced Reliability:

Single cartridge mechanical seals are known for their dependable performance. The standardized design and quality manufacturing ensure consistent sealing in demanding applications.

D. Improved Safety:

By preventing fluid leakage, single cartridge mechanical seals help maintain a safe and clean working environment. This reduces the risk of accidents, contamination, and damage to equipment.

III. Applications of Single Cartridge Mechanical Seals

A. Oil and Gas Industry:

In the oil and gas sector, single cartridge mechanical seals are widely used in pumps for crude oil, refined products, and natural gas processing. They ensure reliable and efficient operations while minimizing environmental impact.

B. Chemical Industry:

Chemical processing plants rely on single cartridge mechanical seals to handle corrosive, toxic, and volatile substances. The seals provide leak-free performance, ensuring worker safety and preventing product contamination.

C. Water Treatment:

In water treatment facilities, single cartridge mechanical seals are essential components of pumps used for filtration, desalination, and wastewater treatment. They maintain the required fluid flow while preventing water loss and contamination.

D. Pharmaceutical Industry:

Pharmaceutical manufacturing requires strict adherence to hygiene and safety standards. Single cartridge mechanical seals are used in pumps that handle drug components, ensuring sterile and uncontaminated processes.

E. Food and Beverage Industry:

From dairy processing to brewing, single cartridge mechanical seals play a crucial role in maintaining product integrity. They prevent cross-contamination, provide hygienic sealing, and comply with stringent industry regulations.

IV. Maintenance Tips for Single Cartridge Mechanical Seals

A. Regular Inspection:

Periodically inspect the seal faces for wear, damage, or signs of leakage. Catching issues early can prevent costly repairs or unplanned downtime.

B. Proper Lubrication:

Ensure the seal faces are properly lubricated to minimize friction and heat generation. Follow manufacturer recommendations for lubricant selection and application.

C. Clean Environment:

Maintain a clean and debris-free environment around the mechanical seals. Dust, dirt, or foreign particles can compromise the seal's performance and shorten its lifespan.

D. Correct Alignment:

During installation or maintenance, pay attention to the correct alignment of components. Misalignment can lead to uneven wear, reduced sealing capability, and premature failure.

E. Professional Assistance:

If unsure about maintenance or repairs, seek professional assistance from trained technicians or the seal manufacturer. Improper handling can cause further damage or compromise seal performance.

Conclusion:

Single cartridge mechanical seals provide a reliable and efficient sealing solution for a wide range of industrial applications. With their easy installation, minimal downtime, and exceptional performance, these seals ensure fluid containment and prevent leakage. By following proper maintenance practices, users can maximize the lifespan and effectiveness of single cartridge mechanical seals, resulting in cost savings and improved operational performance.