Preventative Maintenance Practices for Prolonging the Life of Flygt Mechanical Seals

Preventative Maintenance Practices for Prolonging the Life of Flygt Mechanical Seals

Introduction:

Mechanical seals are critical components in Flygt pumps, ensuring a tight seal between the rotating shaft and the pump housing. To ensure the longevity and efficient operation of Flygt pumps, it is essential to implement preventative maintenance practices for Flygt mechanical seals. This article examines five crucial strategies to prolong the life of these seals and reduce downtime and maintenance costs.

1. Understanding the Role of Flygt Mechanical Seals:

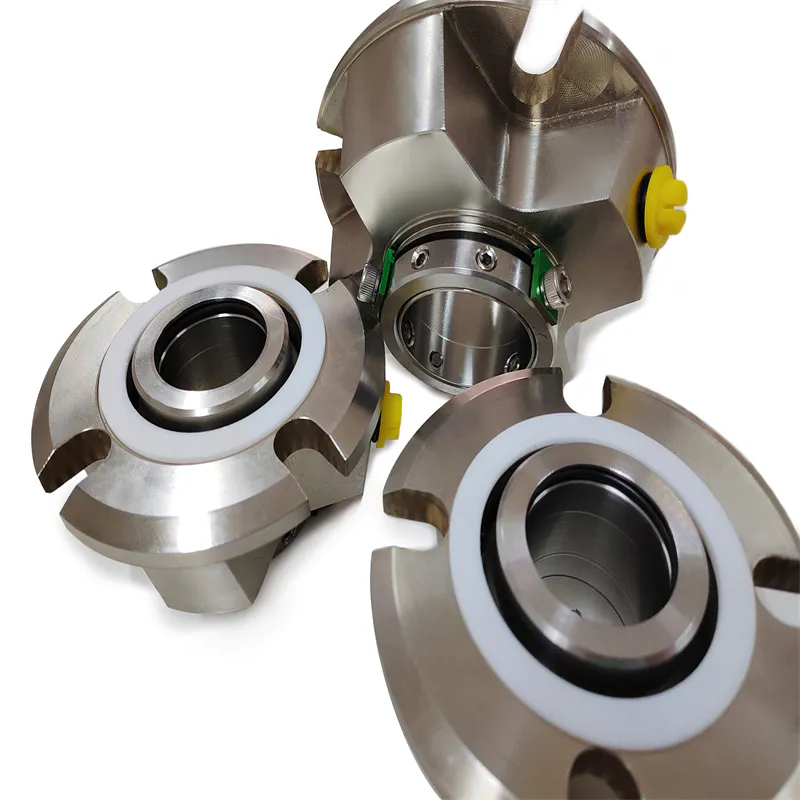

Flygt mechanical seals play a vital role in preventing leakage and maintaining pump efficiency. They consist of two primary components – a stationary seal ring fixed to the pump housing and a rotating seal ring attached to the shaft. When the pump is operational, the seal rings maintain contact, forming a tight seal that prevents fluid leakage. Regular inspections and maintenance of these seals are essential to avoid costly pump failures.

2. Implementing a Routine Inspection Schedule:

Regular inspection of Flygt mechanical seals is crucial for their optimal performance. A routine inspection schedule should be established to monitor the seals' condition and detect any early signs of wear or damage. Visual inspections should include checking for leaks, inspecting the sealing faces for damage or wear, and examining the integrity of the elastomers and springs. It is recommended to conduct inspections at least every three to six months, or as suggested by the manufacturer.

3. Proper Lubrication and Cooling:

Lubrication and cooling are vital for ensuring the smooth operation and prolonged life of Flygt mechanical seals. Applying the correct lubricant, as recommended by the manufacturer, is essential. This helps reduce friction, wear, and heat generation between the seal faces. Additionally, proper cooling mechanisms should be in place to prevent overheating of the seals. Cooling can be achieved through proper design, efficient fluid circulation, or the installation of cooling jackets, depending on the pump application.

4. Maintain Clean and Optimal Operating Conditions:

Maintaining clean and optimal operating conditions is crucial for prolonging the life of Flygt mechanical seals. A buildup of debris, dirt, or abrasive particles can accelerate seal wear and affect sealing performance. Regular cleaning of the pump's surroundings, as well as its suction and discharge lines, can help prevent such contamination. Moreover, it is essential to ensure the system is operated within the recommended range of temperature, pressure, and fluid compatibility to avoid undue stress on the seals.

5. Effective Training and Operator Awareness:

Educating operators and maintenance personnel about the correct handling, installation, and maintenance practices for Flygt mechanical seals is crucial for their longevity. Operators should be trained on proper pump startup and shutdown procedures, as incorrect procedures can lead to premature seal failure. Additionally, operators should be made aware of the importance of monitoring seal performance, recognizing warning signs, and reporting any abnormalities promptly. Well-informed staff can contribute significantly to the overall effectiveness of preventative maintenance practices.

Conclusion:

Implementing preventative maintenance practices for Flygt mechanical seals is essential for maximizing their operational lifespan and minimizing costly pump failures. Regular inspections, proper lubrication and cooling, maintaining clean operating conditions, and effective operator training are all vital factors in prolonging the life of these seals. By following these practices, pump operators can ensure the optimum performance of their Flygt pumps, resulting in reduced downtime, improved efficiency, and significant cost savings.