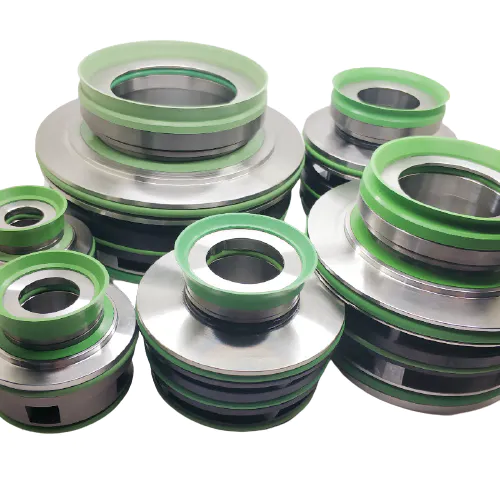

Optimizing System Performance with Customized Grundfos Pump Mechanical Seals

Industrial systems heavily rely on pumps to convey fluids and maintain smooth operations. These pumps perform numerous critical tasks, such as delivering water, chemicals, or other liquids within various applications. However, even the most robust pump systems can experience issues that disrupt their anticipated performance and efficiency. Leaks, wear, and tear, and other system malfunctions are all common culprits. To tackle these challenges and ensure optimal system performance, customized Grundfos pump mechanical seals offer an excellent solution. By implementing tailored seals, industrial facilities can enhance reliability, reduce downtime, and minimize maintenance costs. This article will delve into the advantages of customized seals and provide insights into their various applications.

Ensuring a Leak-Free Environment for Enhanced Productivity

Throughout industrial processes, leaks can cause a multitude of problems. Not only do they lead to fluid loss and wasted resources, but they can also pose safety risks and environmental hazards. Grundfos pump mechanical seals are designed to create a leak-free environment by effectively sealing the shaft, preventing any fluid from escaping the system.

Sealing systems play a pivotal role in numerous industries. For instance, in the oil and gas sector, mechanical seals are used extensively in pumps to maintain optimal production levels. These customized seals provide a reliable solution to prevent leakage and ensure the safe processing of fluids, whether during extraction, refining, or transportation.

Moreover, in chemical plants, where the handling of corrosive and hazardous substances is prevalent, the implementation of customized mechanical seals is vital. These seals are engineered to withstand the harsh chemical environments, effectively containing the fluids and preventing any escape that could lead to accidents or damage to the facility.

By utilizing customized Grundfos pump mechanical seals, industrial systems can operate with confidence, knowing that their pumps are effectively sealed and the risks associated with leaks are mitigated.

Enhanced Durability and Performance with Customized Designs

One of the key advantages of customized Grundfos pump mechanical seals is their ability to be tailored to specific system requirements. Traditional off-the-shelf seals may not always offer an optimum fit, leading to premature wear and decreased performance. In contrast, customized seals ensure a perfect match to the specific pump model. This tailored approach enhances durability and performance, resulting in prolonged pump lifespan and reduced maintenance costs.

Customized seals are designed to withstand challenging operating conditions and varying fluid properties. For instance, certain applications may necessitate seals capable of handling high temperatures or pressure differentials. By working closely with manufacturers, industrial facilities can identify their unique needs and obtain seals that are designed to operate optimally within those parameters.

Moreover, specialized designs can help minimize the risk of vibration and shaft deflection, resulting in improved pump performance. By reducing stress on the shaft and bearings, customized seals contribute to smoother and more efficient operations. This enhanced performance translates into energy savings and increased overall productivity.

Reduced Downtime and Maintenance Costs

When a pump system fails or requires frequent maintenance, it directly impacts productivity and profitability. Downtime can be a substantial financial burden, particularly in industries where operations run around the clock. Customized Grundfos pump mechanical seals help mitigate these issues by ensuring reliable and uninterrupted pump performance.

By opting for customized seals, facilities can experience longer periods between maintenance intervals, minimizing the need for frequent seal replacements. The tailored design, coupled with high-quality materials, allows seals to withstand demanding conditions and extend their service life. This translates into reduced downtime, as maintenance resources can be allocated to other critical areas rather than continually addressing seal failures.

Additionally, the reduced maintenance frequency directly impacts overall costs. Customized seals, with their enhanced durability, can significantly decrease the expenditure associated with seal replacements and repairs. This cost-effectiveness makes customized seals a valuable long-term investment, both in terms of improved system performance and reduced operational expenses.

Applications and Industries

The benefits of customized Grundfos pump mechanical seals extend across various industries and applications. These seals are indispensable in sectors that rely heavily on pumps, such as oil and gas, chemical processing, water treatment, and manufacturing.

In the oil and gas industry, customized mechanical seals play a crucial role in submersible pumps utilized for offshore drilling operations. The seals operate in high-pressure and corrosive environments, ensuring the safety and reliability of extraction processes. In refineries, mechanical seals are vital in preventing leaks and ensuring the efficient processing of petroleum products.

Chemical processing plants present a diverse range of challenges due to the nature of the substances handled. Customized seals are designed to withstand corrosive fluids and high temperatures, safeguarding personnel and equipment integrity. Whether in pumps used for chemical transfer, dosing, or processing, customized seals provide the necessary support for uninterrupted operations.

Water treatment facilities heavily rely on reliable pump systems to handle the treatment and distribution of water. Customized pump seals help maintain the efficiency of these systems by preventing leaks and optimizing pump performance. From wastewater treatment plants to desalination facilities, tailored seals ensure dependable operations and regulatory compliance.

In manufacturing, customized seals find application in pumps used for various purposes, such as coolant circulation, material transfer, or hydraulic systems. The ability to match the seal design to specific manufacturing requirements enhances system performance, ultimately optimizing productivity and reducing maintenance needs.

In Summary

Customized Grundfos pump mechanical seals provide an effective solution to optimize system performance in industrial applications. By creating a leak-free environment, these seals enhance productivity, safety, and environmental compliance. Their tailored design ensures a reliable fit, resulting in increased durability and performance while minimizing maintenance costs. Industries ranging from oil and gas to chemical processing, water treatment, and manufacturing can benefit from these customized seals to achieve seamless operations and improved profitability. With the ability to withstand challenging conditions and varied fluid properties, customized seals offer a powerful tool for enhancing system performance and efficiency.