Optimizing Sealing Performance: Lubrication Considerations for Metal Bellows Seals

Introduction:

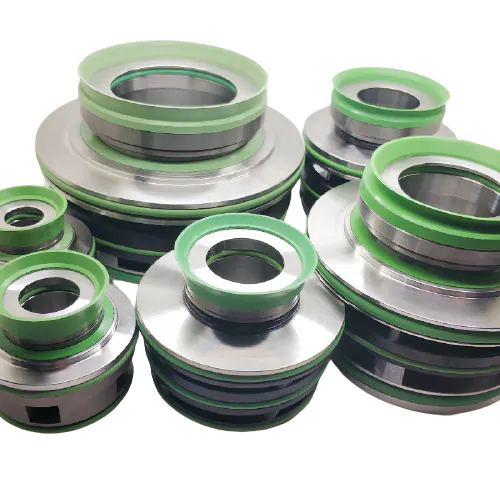

Metal bellows seals are widely used in various industries, including oil and gas, chemical processing, and power generation, to provide effective sealing solutions for pumps and compressors. These seals play a critical role in preventing leakage and maintaining equipment performance. However, to ensure optimal sealing performance, proper lubrication is essential. In this article, we will explore the significance of lubrication considerations for metal bellows seals and discuss various factors that impact their effectiveness.

Importance of Lubrication in Metal Bellows Seals

Lubrication is a vital aspect of metal bellows seals as it influences their performance, reliability, and longevity. The primary role of lubrication is to reduce friction and wear between the sealing surfaces, ensuring smooth operation and minimal power consumption. Additionally, lubrication helps dissipate heat generated during seal operation and provides a protective barrier against corrosion and contamination. Without adequate lubrication, metal bellows seals may experience premature failures, resulting in costly downtimes and potential safety hazards.

Proper lubrication is vital to extend the lifespan of metal bellows seals and optimize their sealing performance. Neglecting lubrication requirements can lead to accelerated wear, increased leakage, and reduced efficiency. Therefore, it is crucial to consider various factors that affect lubrication effectiveness and implement appropriate lubrication strategies.

Factors Influencing Lubrication Effectiveness

1. Operating Conditions: The operating conditions, such as temperature, pressure, and speed, significantly impact the lubrication requirements of metal bellows seals. Higher temperatures increase the likelihood of lubricant degradation, necessitating the selection of suitable lubricants capable of withstanding elevated temperatures. Similarly, high pressures and speeds demand lubricants with exceptional film strength and viscosity characteristics to ensure effective lubrication throughout the operating range.

2. Sealing Surface Materials: The choice of sealing surface materials also affects lubrication effectiveness. Different materials exhibit varying levels of compatibility with lubricants. For instance, certain materials may require specific lubricants to maintain optimal performance, while others may be highly sensitive to lubricant contaminants. It is essential to consider the sealing surface materials and select lubricants that are compatible with these materials to avoid potential compatibility issues and ensure reliable sealing.

3. Lubricant Selection: The selection of the appropriate lubricant is crucial for optimizing sealing performance. Factors such as viscosity, temperature resistance, lubricant additives, and compatibility with sealing materials should be considered. Choosing a lubricant with the correct viscosity ensures sufficient lubrication film thickness, reducing friction and wear. Lubricants with additives like anti-wear agents, corrosion inhibitors, and antioxidants enhance the performance and longevity of metal bellows seals. Additionally, compatibility with sealing materials prevents chemical reactions that may deteriorate the seal's integrity.

4. Lubrication Method: The method of lubricant application also impacts its effectiveness. Different metal bellows seals may require specific lubrication methods, such as oil bath lubrication, oil mist lubrication, or grease lubrication. Each method has its advantages and limitations, depending on the application requirements. Proper lubrication methods ensure uniform distribution of the lubricant and prevent over-lubrication or under-lubrication, which can both lead to performance issues.

5. Maintenance and Monitoring: Regular maintenance and monitoring practices are essential for optimizing lubrication effectiveness in metal bellows seals. This includes scheduled lubricant replacement, inspection of lubricant quality and quantity, and monitoring of seal performance indicators such as leakage rates and temperature. Prompt identification and rectification of any lubrication-related issues contribute to improved sealing performance and reliability.

Summary

Optimizing sealing performance in metal bellows seals relies heavily on lubrication considerations. Proper lubrication ensures minimal friction, reduced wear, and enhanced equipment efficiency. To achieve this, factors such as operating conditions, sealing surface materials, lubricant selection, lubrication methods, and maintenance practices should be carefully evaluated and implemented. Neglecting lubrication requirements can result in premature seal failure, increased downtime, and compromised safety.

By prioritizing lubrication considerations and implementing robust lubrication strategies, industries can optimize the performance, reliability, and lifespan of metal bellows seals, ultimately leading to improved operational efficiency and reduced maintenance costs. Remember, a well-lubricated metal bellows seal is a reliable seal.