Metal Bellows Seals: The Cutting-Edge of High-Performance Sealing

Metal Bellows Seals: The Cutting-Edge of High-Performance Sealing

Introduction:

In the realm of industrial sealing technology, metal bellows seals have emerged as the epitome of high-performance solutions. With their unparalleled ability to handle extreme temperatures, pressures, and corrosive environments, metal bellows seals have revolutionized various industries such as oil and gas, chemical processing, and aerospace. This article delves into the intricate details of metal bellows seals, exploring their design, mechanisms, applications, benefits, and advancements.

I. Understanding Metal Bellows Seals

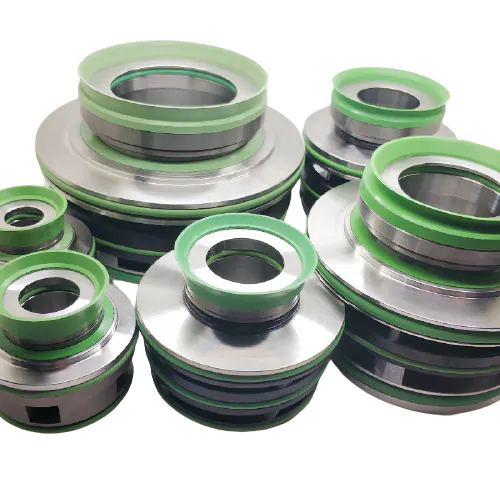

Metal bellows seals, also known as mechanical seals, are sophisticated devices that prevent leakage and ensure the integrity of fluid systems while withstanding challenging operating conditions. These seals utilize a combination of metal bellows, a stationary seal face, and a rotating seal face to create a highly effective barrier against leaks and contamination.

II. The Inner Workings

1. Metal Bellows: The Heart of the Seal

At the core of metal bellows seals lies a bellows element, typically made of stainless steel. This essential component serves as a flexible, spring-like structure that accommodates axial, angular, and lateral movements. Metal bellows are engineered in a convoluted shape, resembling a series of interconnected convolutions or corrugations, which provide flexibility without sacrificing strength.

2. Stationary and Rotating Seal Faces

To effectively seal a fluid system, metal bellows seals employ two primary seal faces – the stationary seal face and the rotating seal face. The stationary seal face is pressed against the housing, while the rotating seal face is attached to the rotating shaft. Together, these seal faces create a dynamic interface that prevents fluid leakage when subjected to high pressures and rotational forces.

III. Applications of Metal Bellows Seals

1. Oil and Gas Industry

Metal bellows seals have found extensive use in the oil and gas sector, where they perform admirably in downstream refining operations, pipeline connections, and subsea applications. Their ability to withstand extreme temperatures and pressures, resist corrosive fluids, and maintain reliable sealing make them an ideal choice for critical equipment such as pumps, compressors, and valves.

2. Chemical Processing

In the chemical processing industry, corrosive substances and hazardous chemicals demand robust sealing solutions. Metal bellows seals, with their excellent resistance to corrosive environments, provide reliable protection in reactor vessels, mixers, agitators, and pumps. Their ability to handle high-speed applications without compromising on safety makes them indispensable in this field.

3. Aerospace Engineering

The aerospace industry relies heavily on metal bellows seals to maintain the integrity of aircraft engines, hydraulic systems, and fuel transfer systems. With their exceptional ability to withstand extreme temperatures, pressure differentials, and exposure to aviation fuels, metal bellows seals ensure the safety and efficiency of critical aerospace applications.

4. Power Generation

The demanding conditions present in power generation facilities necessitate sealing solutions that can withstand high temperatures and pressures. Metal bellows seals are extensively used in turbines, steam generators, gas compressors, and nuclear power applications. They exhibit excellent stability, resilience, and leak-free performance, contributing to the efficiency and reliability of power generation operations.

5. Automotive Industry

Metal bellows seals are also making their mark in the automotive sector due to their ability to seal automotive air conditioning systems effectively. The compact design, low leakage rates, and long lifecycles of these seals make them a preferred choice in ensuring optimal performance and efficiency in the automotive industry.

IV. Advancements in Metal Bellows Seal Technology

1. Advanced Materials

Manufacturers are constantly exploring new materials with enhanced properties to improve the performance of metal bellows seals. These include super alloys, ceramic composites, and specialized coatings that deliver enhanced corrosion resistance, reduced wear, and extended service life.

2. Enhanced Design Features

Ongoing research and development efforts have resulted in innovative design improvements for metal bellows seals. These include optimized geometry, reduced internal stresses, and advanced cooling mechanisms to ensure reliable performance even in the most demanding applications.

3. Smart Sealing Solutions

With the advent of the Internet of Things (IoT), metal bellows seals are being integrated with sensor technologies to enable real-time monitoring of seal conditions. This helps in predictive maintenance, reduces downtime, and enhances overall system efficiency.

4. Environmental Sustainability

Embracing the global focus on sustainability, manufacturers are now developing metal bellows seals that minimize energy losses, reduce emissions, and require less maintenance. Such eco-friendly designs contribute to energy conservation and lower carbon footprints in various industrial sectors.

Conclusion:

Metal bellows seals have truly revolutionized the realm of high-performance sealing. With their remarkable ability to withstand extreme conditions while ensuring reliable sealing, these seals continue to nurture progress in industries ranging from oil and gas to aerospace and automotive. As research and technological advancements continue, metal bellows seals will continue to push the boundaries of what is possible, providing sealing solutions for the most challenging applications.