Maximizing Efficiency: Upgrading to Advanced Tungsten Carbide Seal Rings

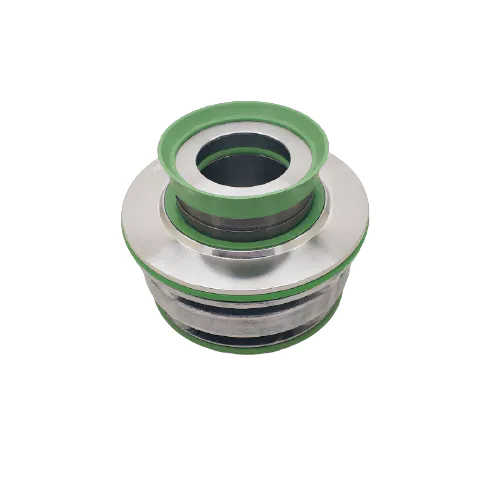

When it comes to industrial equipment, efficiency is key. Companies across various sectors are constantly seeking ways to maximize efficiency and optimize performance. One often-overlooked component that plays a crucial role in this regard is the seal rings used in machinery. Upgrading to advanced tungsten carbide seal rings can significantly improve equipment performance, reduce maintenance costs, and increase overall efficiency. In this article, we will explore the benefits and applications of these advanced seal rings, as well as their impact on industrial processes.

The Importance of Seal Rings in Industrial Machinery

Seal rings are essential components in machinery, particularly in equipment that handles liquids or gases. They provide a tight seal, preventing leakage and maintaining the integrity of the system. In industries such as oil and gas, chemical processing, power generation, and manufacturing, avoiding costly leaks and downtime is crucial. Traditional seal ring materials, such as carbon or ceramics, have limitations that can hinder performance and reliability.

The Promise of Advanced Tungsten Carbide Seal Rings

Tungsten carbide is a versatile and durable material that is revolutionizing the seal ring industry. Made from a combination of tungsten and carbon, it exhibits exceptional hardness, wear resistance, and thermal stability. These properties make it an ideal material for demanding industrial applications. When used as a coating on seal rings, tungsten carbide provides several key advantages over traditional materials, including:

1. Enhanced Wear Resistance and Longevity: Tungsten carbide seal rings have significantly higher wear resistance compared to traditional materials. This means they can withstand high-speed rotations and abrasive environments without deteriorating. The superior durability of tungsten carbide seals translates into longer service intervals and reduced maintenance costs.

2. Improved Sealing Performance: The exceptional hardness of tungsten carbide ensures a tight and reliable seal, even under extreme pressure and temperature conditions. This results in reduced leakage rates, improved system efficiency, and enhanced safety.

3. Corrosion and Chemical Resistance: Tungsten carbide is highly resistant to corrosion and chemical attack. This makes it an excellent choice for applications involving corrosive fluids, acids, and alkalis. The corrosion resistance of tungsten carbide seal rings extends their service life and offers added protection to the machinery they are installed in.

4. Thermal Stability: Tungsten carbide can withstand extreme temperatures without losing its structural integrity or performance properties. This makes it suitable for applications where heat dissipation or high-temperature resistance is critical. Whether it's high-speed rotating machinery or operations involving thermal cycling, tungsten carbide seal rings can maintain their effectiveness, ensuring continued efficiency and reliability.

5. Compatibility: Tungsten carbide seal rings are compatible with a wide range of fluids, including oils, chemicals, and gases. This versatility allows them to be used in diverse industrial processes, making them a go-to choice for many equipment manufacturers and operators.

Applications of Advanced Tungsten Carbide Seal Rings

The benefits of advanced tungsten carbide seal rings extend to a wide range of industrial applications. Here are a few examples:

1. Pumps and Compressors: In pumping systems, seal rings play a crucial role in preventing leakage and maintaining system efficiency. Tungsten carbide seal rings are widely used in centrifugal pumps, diaphragm pumps, reciprocating pumps, and compressors. Their high wear resistance and reliability make them an excellent choice for these demanding applications.

2. Valves and Actuators: Valves regulate the flow of fluids within a system, and actuator systems control their operation. Tungsten carbide seal rings ensure tight and effective sealing in both valves and actuators, resulting in improved system performance and reduced maintenance requirements.

3. Turbomachinery: Turbomachinery, such as turbines and turbo compressors, operates at high speeds and under extreme conditions. Upgrading to tungsten carbide seal rings significantly enhances the efficiency and reliability of these machines, reducing the risk of downtime and costly repairs.

4. Mixers and Agitators: Mixing and agitation processes often involve corrosive or abrasive substances. Tungsten carbide seal rings provide excellent sealing performance in mixers and agitators, ensuring safe and efficient operations.

5. Hydraulic Systems: Hydraulic systems rely on seals to maintain pressure and prevent leakage. Tungsten carbide seal rings deliver superior sealing performance in hydraulic applications, allowing for efficient power transmission and improved system reliability.

Summary

Upgrading to advanced tungsten carbide seal rings offers numerous benefits for industrial equipment. Improved wear resistance, enhanced sealing performance, corrosion resistance, thermal stability, and compatibility with various fluids are just a few advantages these seal rings bring to the table. From pumps and compressors to valves, turbomachinery, mixers, agitators, and hydraulic systems, the applications for tungsten carbide seal rings are vast. By utilizing this advanced technology, companies can maximize efficiency, reduce maintenance costs, and improve overall productivity. So, consider upgrading to advanced tungsten carbide seal rings for your machinery and unlock the full potential of your industrial processes.