Enhancing Pump Reliability with High-Performance Grundfos Mechanical Seals

Enhancing Pump Reliability with High-Performance Grundfos Mechanical Seals

Introduction

Pumps are essential components of various industries, including oil and gas, water treatment, manufacturing, and more. They are responsible for the transportation of liquids and gases in a controlled manner. However, pump failures can lead to costly downtime, maintenance, and repairs. Therefore, it is crucial to ensure their reliability and efficiency for optimal operation. One significant factor that contributes to pump reliability is the quality of the mechanical seals used. In this article, we will explore how high-performance Grundfos mechanical seals are enhancing pump reliability.

1. Understanding Mechanical Seals in Pumps

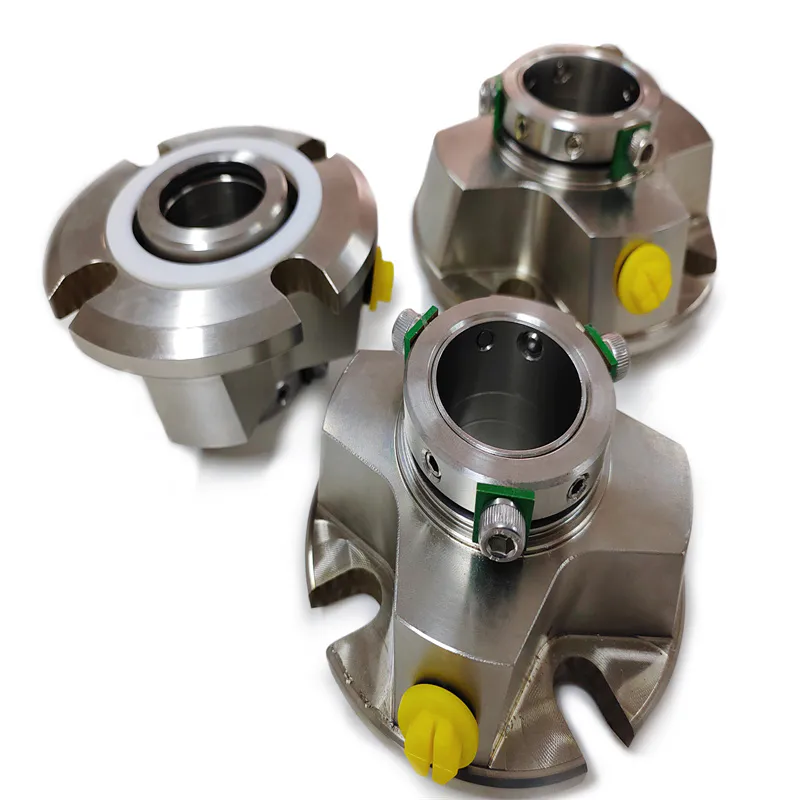

Mechanical seals are crucial sealing elements used in pumps to prevent leakage of fluids. They are designed to withstand high pressures and temperatures while maintaining a tight seal. A mechanical seal typically consists of two primary components: a stationary part attached to the pump housing and a rotating part attached to the pump shaft. When these two parts come into contact, they create a seal that prevents fluid from leaking out.

2. The Importance of Reliable Mechanical Seals

2.1 Preventing Leakage

The primary function of mechanical seals is to prevent fluid leakage from pumps. This is crucial in industries where even minor leaks can lead to environmental pollution, safety hazards, and financial losses. High-performance mechanical seals ensure a tight seal, minimizing the risk of leakage and its associated consequences.

2.2 Increasing Pump Efficiency

Reliable mechanical seals not only prevent leakage but also contribute to the overall efficiency of a pump. When a seal is worn out or poorly designed, it can create friction, leading to increased energy consumption and reduced pump performance. High-performance seals, like those offered by Grundfos, are designed to minimize friction and maximize pump efficiency, resulting in energy savings and improved operation.

3. Grundfos Mechanical Seals: Enhancing Reliability through Innovation

3.1 Advanced Materials

Grundfos, a leading global provider of pump solutions, has been at the forefront of mechanical seal innovation. Their high-performance seals are manufactured using advanced materials that offer excellent durability and reliability. These materials are carefully selected to handle harsh operating conditions, corrosive fluids, and extreme temperatures.

3.2 Robust Design

In addition to advanced materials, Grundfos mechanical seals feature a robust design that can handle demanding applications. The seals are engineered to withstand high pressures, vibrations, and axial movements while maintaining a consistent seal. This ensures long-lasting performance and reduces the likelihood of unexpected failures.

4. Benefits of Grundfos Mechanical Seals

4.1 Extended Service Life

One of the primary benefits of using high-performance Grundfos mechanical seals is an extended service life of pumps. These seals are built to withstand demanding conditions, reducing the frequency of seal replacements and overall downtime. By investing in reliable seals, industries can save on maintenance costs and increase operational efficiency.

4.2 Enhanced Seal Performance

Grundfos mechanical seals are designed to provide optimal performance in critical applications. They offer superior sealing capabilities, ensuring minimal leakage and improved pump efficiency. The advanced design and materials used in these seals contribute to higher reliability, allowing pumps to operate smoothly without interruptions.

4.3 Improved Environmental Protection

Leaks from pumps can have severe environmental consequences. Grundfos mechanical seals play a vital role in preventing fluid leakage and protecting the environment. By utilizing high-performance seals, industries can maintain compliance with environmental regulations, minimize the risk of pollution, and demonstrate their commitment to sustainability.

5. Case Study: Pump Reliability in the Oil and Gas Industry

The oil and gas industry heavily relies on pumps for various applications, such as crude oil transportation, refining processes, and offshore drilling. Pump failures in this sector can result in significant financial losses and environmental damage. To ensure the reliability of pumps, many oil and gas companies have turned to Grundfos mechanical seals.

One notable case study involves an offshore oil rig that experienced frequent pump failures due to seal leakage. These failures not only disrupted production but also raised concerns about the potential for oil spills in the ocean. After implementing Grundfos high-performance mechanical seals, the oil company noticed a significant decrease in pump failures and improved overall reliability. The seals' ability to withstand corrosive seawater and high-pressure conditions proved essential in maintaining smooth operations.

Conclusion

In conclusion, reliable mechanical seals play a crucial role in enhancing pump reliability. High-performance Grundfos mechanical seals offer advanced features and materials designed to withstand harsh conditions, prevent leakage, and increase pump efficiency. By investing in these seals, industries can ensure extended service life, improved environmental compliance, and reduced maintenance costs. Grundfos continues to innovate and provide cutting-edge solutions for various pump applications, further solidifying their position as a trusted partner in the industry.