Chemical Process Pump Sealing Solutions: Enhancing Reliability and Safety

Chemical Process Pump Sealing Solutions: Enhancing Reliability and Safety

Introduction

Chemical process pumps play a vital role in various industries, such as oil refining, chemical manufacturing, and wastewater treatment. These pumps are used to transfer corrosive fluids, hazardous chemicals, and abrasive slurries. To ensure the smooth and efficient operation of these pumps, it is crucial to have reliable sealing solutions in place. This article delves into the importance of chemical process pump sealing solutions and explores the various options available to enhance reliability and safety.

Understanding the Challenges

Chemical process pumps handle aggressive substances, high pressures, and extreme temperatures. As a result, the sealing systems used in these pumps must be designed to withstand these challenging conditions. The challenges faced by sealing solutions in chemical process pumps include:

1.1 Corrosion Resistance

Corrosion is a significant concern when dealing with aggressive chemicals. Sealing solutions must be able to resist corrosion and degradation over an extended period. Materials such as stainless steel, fluorocarbons, and ceramic composites are commonly used for their superior corrosion resistance properties.

1.2 Leakage Prevention

Preventing leakage is crucial not only for the efficient operation of the pump but also to maintain the safety of personnel and the environment. Sealing solutions need to provide a tight seal to prevent any leaks, even under high pressures and temperature variations.

1.3 Wear and Tear

Chemical process pumps often encounter abrasive substances that can cause wear and tear on the sealing components. Therefore, the sealing solutions should possess excellent resistance to abrasion and erosion, ensuring longevity and reducing maintenance costs.

1.4 High Temperatures

Certain chemical processes involve high-temperature fluids, which put additional strain on the sealing systems. Sealing solutions must be able to withstand these extreme temperatures without compromising integrity.

1.5 Regulatory Compliance

Safety regulations and standards set by regulatory bodies, such as the Occupational Safety and Health Administration (OSHA), impose stringent requirements for chemical process pump sealing solutions. Compliance with these standards is crucial to avoid penalties, accidents, and environmental hazards.

Types of Sealing Solutions

To meet the challenges faced by chemical process pumps, several sealing solutions are available in the market. Each solution has its unique advantages depending on the specific application and process requirements. Some common sealing solutions include:

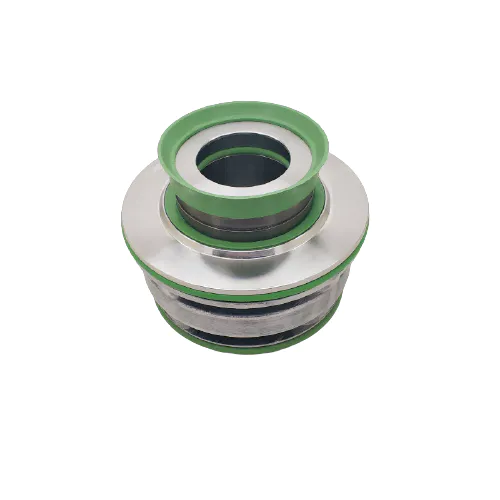

2.1 Mechanical Seals

Mechanical seals are widely used in chemical process pumps due to their reliability and ability to withstand high pressures. These seals consist of two primary components: a rotating element and a stationary element. The rotating element is connected to the pump shaft, while the stationary element is mounted in the pump's casing. This configuration ensures a tight seal and prevents leakage.

2.2 Gland Packing

Gland packing, also known as stuffing box packing, has been a traditional sealing solution for chemical process pumps. It involves filling the space between the pump shaft and the casing with flexible materials, such as braided fibers or graphite. Gland packing provides a relatively simple and cost-effective sealing solution, but it requires periodic maintenance and adjustment to control leakage.

2.3 Magnetic Drive Pumps

Magnetic drive pumps offer a unique sealing solution by eliminating the need for dynamic seals. These pumps use a magnetic coupling to transmit power from the motor to the impeller, eliminating leakage risks associated with mechanical seals. Magnetic drive pumps are ideal for handling high-purity fluids or toxic substances that require absolute leak-free operation.

2.4 Double Mechanical Seals

Double mechanical seals offer an additional layer of protection by incorporating two sets of mechanical seals with a barrier fluid in between. This configuration provides enhanced sealing performance, especially in critical applications that demand zero leakage.

2.5 Cartridge Seals

Cartridge seals are preassembled units that simplify the installation process and eliminate the need for precise adjustment. These seals come as a complete package, including all necessary components such as seal faces, springs, and gland plate. Cartridge seals offer excellent sealing performance and reduce the risk of installation errors.

Advantages of Reliable Sealing Solutions

Investing in reliable sealing solutions for chemical process pumps yields several advantages, including:

3.1 Enhanced Safety

By preventing leaks and minimizing the risk of hazardous substance exposure, reliable sealing solutions contribute to a safer working environment for operators and surrounding communities. This promotes workplace safety compliance and prevents potential accidents.

3.2 Improved Efficiency

A tight seal provided by reliable sealing solutions reduces energy losses, improving the overall efficiency of chemical process pumps. Efficient pump operation helps save energy costs and reduces the carbon footprint of industrial processes.

3.3 Extended Equipment Lifespan

Sealing solutions that are resistant to corrosion, wear, and tear ensure longer equipment lifespan. Regular breakdowns and maintenance-related downtime can be minimized, leading to increased productivity and reduced operational costs.

3.4 Regulatory Compliance

Reliable sealing solutions help industries meet regulatory compliance standards, minimizing the risk of penalties and legal consequences. By adhering to stringent safety and environmental regulations, companies can safeguard their reputation and maintain the trust of stakeholders.

3.5 Cost Savings

Investing upfront in reliable sealing solutions may seem costly, but it leads to significant long-term cost savings. Reduced maintenance requirements, extended equipment lifespan, and improved energy efficiency contribute to minimizing operational expenses in the long run.

Conclusion

In the demanding world of chemical process pumps, reliable sealing solutions are essential to ensure the safe and efficient operation of these critical assets. Understanding the challenges faced by these pumps, exploring different sealing options, and investing in quality sealing solutions are crucial steps towards enhancing reliability and safety. By embracing reliable sealing solutions, industries can mitigate risks, improve productivity, and fulfill regulatory requirements, leading to sustainable and successful operations.