Case Studies: Success Stories with Cartridge Seals

Case Studies: Success Stories with Cartridge Seals

Introduction

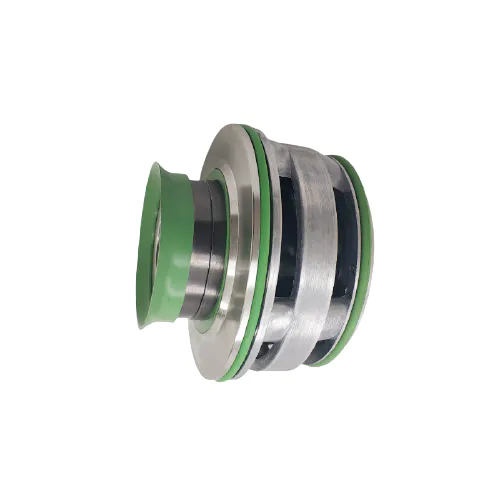

Cartridge seals have gained popularity in various industries due to their efficiency, easy installation, and reliable performance. These mechanical seals provide effective sealing solutions for pumps, compressors, and other rotating equipment. In this article, we will explore some success stories where cartridge seals have significantly improved equipment reliability, reduced downtime, and enhanced overall operational efficiency.

1. Enhancing Pump Performance: A Case Study in the Petrochemical Industry

In the highly demanding petrochemical industry, pump failure can result in costly production interruptions. A leading petrochemical company faced recurring seal failure in their centrifugal pumps, leading to frequent shutdowns and maintenance costs.

After thorough evaluation, the company decided to replace the conventional packing seals with cartridge seals. The cartridge seal installation eliminated the need for routine adjustments and provided a consistent, leak-free seal. This not only reduced seal failure instances but also improved pump performance.

The new cartridge seals proved to be highly reliable, preventing leakages and ensuring continuous operation. As a result, the petrochemical company experienced a significant reduction in maintenance costs and eliminated unplanned downtime caused by seal failures.

2. Improving Efficiency in Wastewater Treatment: A Municipal Plant Case Study

Efficient wastewater treatment is crucial for maintaining environmental standards. A municipal wastewater treatment plant was facing challenges with their aging pumps and frequent seal failures, causing process interruptions and pollution risks.

The plant decided to replace their conventional seals with cartridge seals, taking advantage of their enhanced design and simplified installation process. The retrofitting process was smooth and minimally interrupted plant operations.

The cartridge seals delivered excellent results, significantly reducing leakages and extending the pump's lifespan. By eliminating the need for frequent adjustments, the plant achieved stable and efficient operations. Moreover, the increased reliability of the cartridge seals helped in maintaining a consistent treatment process, ensuring compliance with regulations and minimizing the risk of environmental pollution.

3. Increased Reliability in Power Generation: A Case Study in a Thermal Power Plant

Thermal power plants face immense pressure to operate smoothly and efficiently to meet energy demand. A thermal power plant encountered challenges with recurrent seal failures in their boiler feedwater pumps, leading to frequent downtime and inefficiency.

To address this issue, the plant opted for cartridge seals, which provided a high-performance sealing solution. The installation of cartridge seals required minimal modifications and allowed for a quick turnaround in replacing the failed mechanical seals.

The new cartridge seals demonstrated exceptional performance by eliminating leakages and reducing power losses due to seal inefficiency. The power plant experienced a significant reduction in pump maintenance, resulting in enhanced operational efficiency and increased power generation. The improved reliability of the cartridge seals played a vital role in maintaining uninterrupted operations, ensuring consistent power supply to consumers.

4. Reliability in the Food and Beverage Industry: A Dairy Processing Plant Case Study

In the food and beverage industry, hygiene and productivity are of utmost importance. A dairy processing plant faced challenges with seal failures in their pumps used for milk and dairy product transfer.

By replacing traditional seals with cartridge seals, the dairy plant aimed to enhance productivity, reduce contamination risks, and minimize equipment downtime. The cartridge seals were specifically designed to meet the industry's stringent regulations, ensuring no product contamination and maintaining hygiene standards.

The successful implementation of cartridge seals resulted in reduced maintenance requirements and enhanced equipment reliability. The elimination of leakage issues improved the plant's productivity, ensuring uninterrupted milk processing and minimizing product losses.

5. Enabling Sustainable Mining: A Case Study in the Mining Sector

The mining industry operates under harsh conditions, and equipment reliability and efficiency are crucial for profitability. A mining company faced consistent seal failures in their slurry pumps, leading to excessive maintenance and downtime.

The company embraced the use of cartridge seals to combat these challenges. The cartridge seals provided superior sealing performance, preventing slurry leakage and significantly reducing equipment downtime.

With the introduction of cartridge seals, the mining company experienced a substantial reduction in pump failures, resulting in cost savings and increased productivity. The improved reliability of the seals contributed to sustainable mining practices by reducing environmental risks associated with unexpected leakages.

Conclusion

Through these diverse case studies, it is evident that cartridge seals offer immense benefits in various industries, including improved equipment reliability, reduced maintenance costs, and enhanced operational efficiency. The success stories discussed here highlight the transformative impact cartridge seals can have on pumping systems. Embracing this technology can lead to a significant reduction in downtime, increased productivity, and better compliance with industry regulations. Cartridge seals have emerged as a game-changer in providing reliable and efficient sealing solutions for rotating equipment, ensuring successful and sustainable operations across different sectors.