Cartridge Seals vs. Traditional Seals: Performance Comparison

Cartridge Seals vs. Traditional Seals: Performance Comparison

Introduction

Sealing technology is an integral part of various industries, ensuring that machines and equipment operate efficiently and securely. Over the years, mechanical seals have evolved, leading to the development of cartridge seals, a modern alternative to traditional seals. This article will compare the performance of cartridge seals with traditional seals, examining their durability, ease of installation, maintenance requirements, and cost-effectiveness. By delving into these factors, industries can make informed decisions about which sealing technology best suits their needs.

Durability - A Battle of Endurance

Cartridge Seals: A New Generation of Resilience

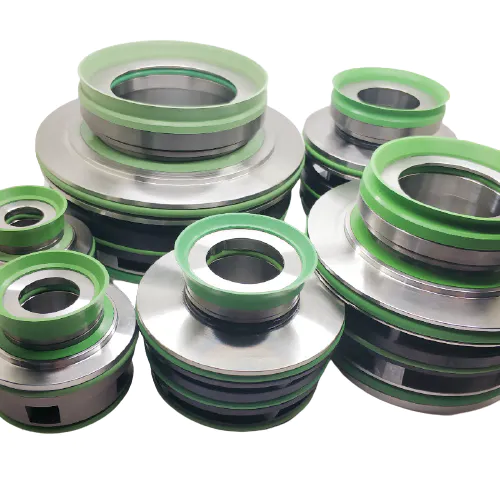

Cartridge seals excel in durability due to their robust design and innovative features. They comprise multiple components arranged in a self-contained unit, providing superior protection against environmental factors such as temperature fluctuations, corrosion, and contamination. The cartridge seal's structure shields vital internal components, enhancing its lifespan and reducing the risk of premature failures.

Traditional Seals: Tried and Tested

Traditional seals have played a significant role in sealing applications for decades and have proven their endurance. However, they lack the integrated design of cartridge seals, making their performance susceptible to external factors. Traditional seals commonly require auxiliary components, such as glands and flush systems, to ensure adequate protection and longevity. While they can withstand regular wear and tear, their durability is not on par with that of cartridge seals.

Installation - Efficiency Matters

Cartridge Seals: Simplifying Installation Procedures

One of the primary advantages of cartridge seals is their user-friendly installation process. These seals come pre-assembled, requiring minimal assembly expertise. With the integrated design, cartridge seals ensure proper alignment and reduce the risk of incorrect installation. This streamlined installation procedure saves time, effort, and resources, allowing industries to maintain operational efficiency.

Traditional Seals: A Labor-Intensive Affair

The installation of traditional seals involves intricate processes and often requires skilled technicians. Various components must be aligned correctly, and additional accessories may be necessary. The time, labor, and costs associated with traditional seal installation can be significant, impacting production timelines and budgets. Moreover, the manual installation process increases the likelihood of human errors, jeopardizing the overall sealing performance.

Maintenance - Balancing Reliability and Ease

Cartridge Seals: A Maintenance Advantage

Cartridge seals are designed to facilitate easy maintenance. As they come in a self-contained unit, maintenance personnel can quickly inspect and replace them without dismantling the entire sealing system. This reduces downtime during maintenance activities, allowing industries to resume operations promptly. The integrated design also minimizes the chances of misalignment during reinstallation, ensuring the seal's performance remains uncompromised.

Traditional Seals: Demanding Maintenance Routines

Maintaining traditional seals can be a time-consuming process. Their multi-component structure often necessitates complete disassembly, increasing the labor and resources required. Additionally, the need for precision alignment during reinstallation adds complexity to the maintenance procedure. These factors contribute to longer downtime and potential productivity losses, making traditional seals more challenging to maintain efficiently.

Cost-Effectiveness - Striking the Right Balance

Cartridge Seals: A Smart Investment

Despite their slightly higher upfront cost compared to traditional seals, cartridge seals offer long-term cost advantages. Their durability and easy maintenance reduce the frequency of replacement or repair cycles, saving on both material and labor expenses. Additionally, the streamlined installation reduces downtime, resulting in higher operational efficiency and increased productivity. Cartridge seals often provide a higher return on investment when industries consider the holistic cost perspective.

Traditional Seals: A Budget-Conscious Option

Traditional seals have a lower initial cost, making them an attractive choice for businesses with tight budgets. However, their frequent maintenance requirements, replacement cycles, and longer downtime contribute to higher long-term costs. While some industries might still benefit from traditional seals based on their specific operational parameters, the cost-effectiveness of traditional seals generally decreases over time.

Conclusion

In the battle between cartridge seals and traditional seals, the former emerges as the modern, efficient, and durable sealing technology. With their integrated design, cartridge seals offer better durability, easy installation procedures, convenient maintenance routines, and long-term cost-effectiveness. While traditional seals still have their place in certain industries, the advantages of cartridge seals, such as enhanced resilience, effortless installation, simplified maintenance, and overall cost savings, cannot be overlooked. By embracing cartridge seals, industries can optimize their sealing system performance, leading to improved productivity and reliability.