Cartridge Seals in Oil and Gas Production: Ensuring Safety and Efficiency

Cartridge Seals in Oil and Gas Production: Ensuring Safety and Efficiency

Introduction

Oil and gas production is a complex process that requires the use of various equipment and components to ensure safety and efficiency. One critical component in this industry is cartridge seals. Cartridge seals play a pivotal role in preventing leaks and preserving the integrity of the machinery used in oil and gas production. This article delves into the importance of cartridge seals and how they contribute to ensuring safety and efficiency.

Overview of Cartridge Seals

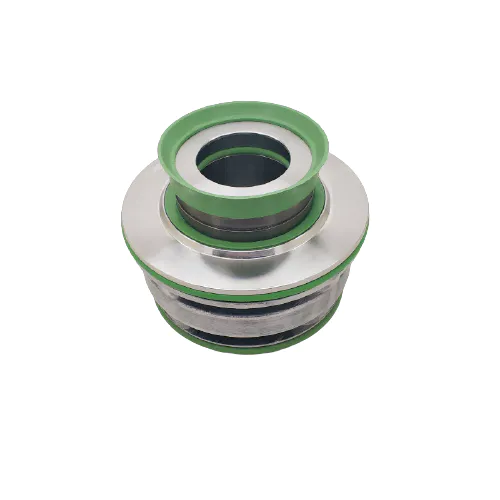

Cartridge seals are mechanical seals that consist of a seal face, a rotating member, and a stationary member, all enclosed in a self-contained cartridge unit. These seals are designed to be pre-assembled and easily replaceable, reducing downtime during maintenance operations. Their compact design makes them suitable for various applications in the oil and gas industry, including pumps, compressors, and mixers.

The Role of Cartridge Seals in Preventing Leaks

One of the primary functions of cartridge seals is to prevent leaks. Leaks can lead to environmental hazards, loss of product, and significant financial losses. Cartridge seals provide a secure and reliable sealing solution by creating a tight barrier between the rotating and stationary parts of the machinery. The self-contained design of these seals ensures that any potential leaks are contained within the cartridge, preventing harm to the surrounding environment.

Enhancing Safety in Oil and Gas Production

Safety is paramount in the oil and gas industry, considering the high-pressure and hazardous substances involved. Cartridge seals play a vital role in enhancing safety by minimizing the risk of equipment failure and subsequent accidents. By effectively sealing the machinery, cartridge seals prevent the escape of hazardous gases, liquids, or vapors, protecting both the workers and the surrounding infrastructure.

Factors Affecting Cartridge Seal Performance

Several factors can impact the performance of cartridge seals in oil and gas production. One crucial factor is the choice of sealing materials. Different operating conditions, such as temperature, pressure, and the nature of the fluids being handled, require specific sealing materials to ensure optimal performance and longevity. Additionally, proper installation, regular maintenance, and adequate lubrication also influence the performance of cartridge seals.

Improving Efficiency in Oil and Gas Operations

Efficiency is a top priority in oil and gas production, as it directly impacts profitability. Cartridge seals contribute to overall operational efficiency by reducing downtime caused by equipment maintenance and repairs. The pre-assembled and self-contained nature of these seals allows for quicker and easier replacement, minimizing the time required for maintenance activities. Furthermore, the reliable sealing provided by cartridge seals improves equipment performance, reducing energy consumption and maximizing productivity.

Advancements in Cartridge Seal Technology

Over the years, cartridge seal technology has advanced significantly, leading to improved performance and reliability. Modern cartridge seals are designed to withstand extreme operating conditions, including high pressures and temperatures. Advanced materials and innovative design features ensure enhanced durability and longer life spans. Additionally, some cartridge seals incorporate monitoring systems that provide real-time data on seal performance, enabling predictive maintenance and preventing unexpected failures.

Conclusion

Cartridge seals play a crucial role in ensuring safety and efficiency in oil and gas production. By preventing leaks, enhancing safety, and improving operational efficiency, these seals contribute to the smooth running of oil and gas operations. With continual advancements in technology, cartridge seals are becoming more reliable, durable, and sustainable. As the oil and gas industry evolves, the demand for high-performing cartridge seals will continue to rise, ensuring a safer and more efficient future for the industry.