Bellows Seals for Cryogenic Transfer Pumps: Flexibility and Low-Temperature Sealing

1. Introduction

Bellows seals play a crucial role in ensuring efficient and reliable cryogenic transfer pumps. These specialized seals provide the necessary flexibility and low-temperature sealing capabilities required in cryogenic applications. In this article, we will delve into the features, benefits, and applications of bellows seals for cryogenic transfer pumps.

2. Understanding Bellows Seals

Bellows seals are mechanical components specifically designed to provide a dynamic seal between two moving parts while allowing relative motion. These seals are commonly used in various industries, including chemical processing, oil and gas, pharmaceuticals, and cryogenic applications. The main purpose of bellows seals is to prevent the leakage of fluids or gases while accommodating axial, lateral, and angular movement.

3. The Importance of Flexibility in Cryogenic Transfer Pumps

Cryogenic transfer pumps are utilized to transfer extremely cold fluids, such as liquefied natural gas (LNG) or liquid nitrogen, from one location to another. These pumps operate in challenging environments with temperatures ranging from -200°C to -270°C (-328°F to -454°F). The extreme low temperatures can cause conventional seals to become rigid, resulting in leakage and decreased pump efficiency. Bellows seals, on the other hand, offer superior flexibility even at cryogenic temperatures, ensuring reliable and leak-free operation.

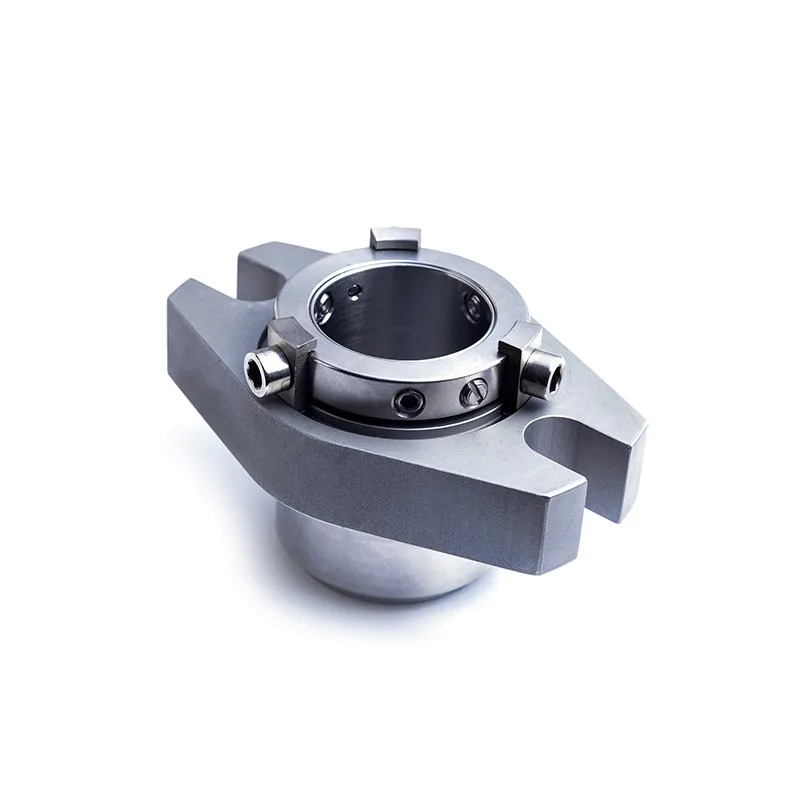

4. Features and Construction of Bellows Seals for Cryogenic Applications

Bellows seals for cryogenic transfer pumps are meticulously engineered to withstand the harsh conditions encountered in extremely cold environments. They are typically constructed using materials with low thermal conductivity, such as stainless steel or titanium, to minimize heat transfer from the pump to the seal. The bellows themselves are often made from high-quality alloys that can withstand extreme temperatures and provide the necessary flexibility.

5. Enhanced Low-Temperature Sealing Performance

Sealing at cryogenic temperatures requires specialized design considerations. Bellows seals for cryogenic transfer pumps are designed to maintain their sealing capabilities in the presence of extreme cold. The seals are often equipped with secondary sealing elements, such as O-rings or gaskets, to provide additional leak protection. These dual-seal arrangements ensure maximum sealing integrity, even in demanding cryogenic applications.

6. Benefits of Using Bellows Seals

Integrating bellows seals into cryogenic transfer pumps offers several significant advantages. Firstly, their exceptional flexibility allows for efficient operation even at extremely low temperatures, preventing leakage and ensuring optimal pump performance. Secondly, the ability of bellows seals to accommodate axial, lateral, and angular movement reduces stress on other pump components, extending the overall lifespan of the pump. Additionally, the use of bellows seals results in improved energy efficiency and reduced maintenance costs.

7. Applications of Bellows Seals in Cryogenic Transfer Pumps

The versatility and reliability of bellows seals make them essential components in various cryogenic transfer pump applications. They are extensively used in the liquefied natural gas (LNG) industry, where the transportation and storage of LNG require specialized pumping systems. Bellows seals ensure the safe and efficient transfer of LNG from storage tanks to transportation vessels, as well as during the regasification process. Moreover, cryogenic transfer pumps used in research laboratories, aerospace, pharmaceutical, and food industries also benefit from the superior sealing performance of bellows seals.

8. Maintenance and Best Practices

To prolong the life of bellows seals and maintain their optimum performance, proper maintenance practices should be followed. Regular inspection and lubrication are crucial to ensure smooth operation and prevent wear. It is important to monitor the temperature and pressure of the system to identify any deviations from normal operating conditions. Additionally, frequent visual checks should be conducted to detect any signs of leakage or damage to the bellows or secondary sealing elements.

9. Conclusion

Bellows seals provide the necessary flexibility and low-temperature sealing capabilities required in cryogenic transfer pumps. They play a vital role in preventing leakage and ensuring reliable operation in extreme cold environments. The exceptional flexibility and ability to accommodate movement make bellows seals indispensable in various industries, particularly in LNG transportation, research laboratories, and pharmaceutical applications. By incorporating bellows seals in cryogenic transfer pumps, operators can enhance efficiency, reduce maintenance costs, and ensure the continuous and safe transfer of cryogenic fluids.