Advantages of Using Metal Bellows Seals in Industrial Applications

Top Reasons to Use Metal Bellows Seals in Industrial Applications

Introduction:

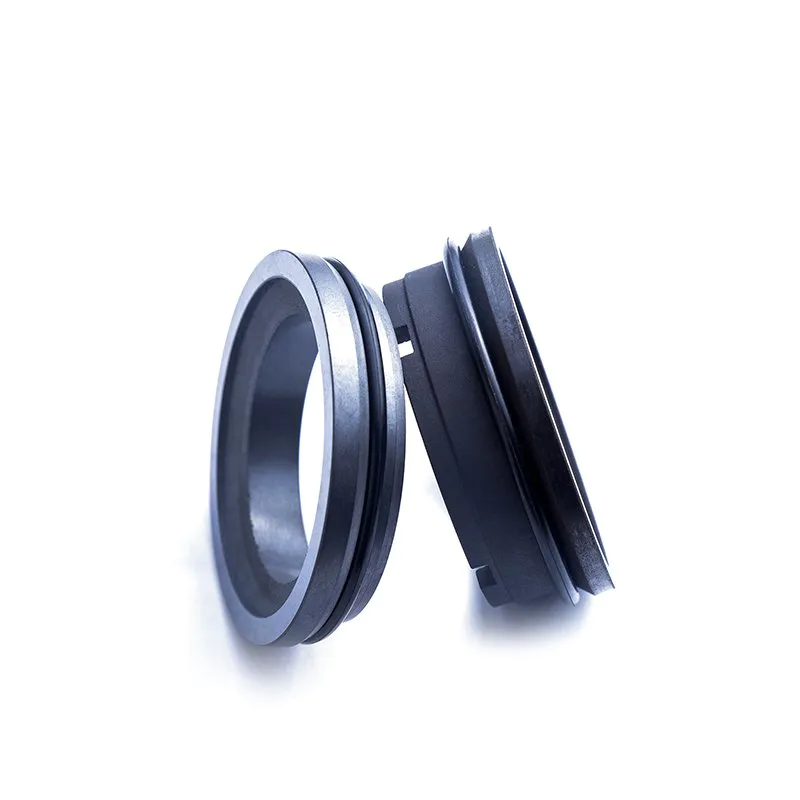

In industrial applications, the choice of sealing solutions plays a critical role in ensuring efficient and reliable performance. One such solution that has gained significant popularity in recent years is the metal bellows seal. With its unique design and exceptional capabilities, the metal bellows seal offers several advantages over traditional sealing methods. This article explores the various benefits of using metal bellows seals in industrial applications and highlights why they have become the preferred choice for many industries worldwide.

Enhanced Flexibility and Durability

Metal bellows seals are designed with a series of convolutions that provide superior flexibility compared to other types of sealing options. These convolutions allow the seal to accommodate axial, angular, and radial shaft movement, making it ideal for applications with varying operating conditions. By reducing stress on the seal faces and shaft, metal bellows seals effectively extend the lifespan of the equipment, leading to reduced downtime and maintenance costs.

The construction of metal bellows seals involves high-quality materials such as stainless steel or other corrosion-resistant alloys, ensuring exceptional durability even in challenging environments. These seals can withstand extreme temperatures, pressure differentials, and aggressive chemicals, making them suitable for a wide range of industrial processes. Moreover, the resistance to corrosion and wear significantly reduces the risk of seal failure, enhancing overall equipment reliability.

Superior Sealing Performance

Metal bellows seals provide an excellent sealing performance, ensuring leak-free operation throughout the lifecycle of the equipment. The unique design of the metal bellows acts as a spring, which applies consistent pressure on the seal faces, maintaining a tight seal. This constant pressure compensates for wear on the seal faces, ensuring a uniform contact area and minimizing leakage.

Furthermore, metal bellows seals offer low friction characteristics, resulting in reduced heat generation during operation. The reduced heat minimizes thermal expansion, allowing for precise dimensional stability and preventing leakage due to seal face distortion. The exceptional sealing performance of metal bellows seals prevents product loss, contamination, and environmental damage, contributing to a safer and more sustainable industrial environment.

Excellent Resistance to Contaminants

Contamination is a common challenge faced in many industrial applications, as it can lead to premature seal failure and equipment downtime. Metal bellows seals, however, provide excellent resistance to various contaminants, ensuring reliable and uninterrupted operation. The convoluted design of the metal bellows acts as a barrier, preventing the ingress of debris, dust, moisture, or other harmful substances that can compromise the sealing performance.

Notably, metal bellows seals are particularly effective in protecting against abrasive particles, such as those found in mining or processing applications. The robust construction of the seals shields the sealing faces, preventing accelerated wear and maintaining optimal performance even in demanding environments. The ability to resist contaminants enhances the longevity of the equipment, reducing maintenance costs, and improving overall productivity.

Wide Range of Applications

Metal bellows seals find extensive use in a diverse range of industrial applications due to their versatility and adaptability. They are suitable for pumps, compressors, mixers, agitators, and other rotating equipment found in various industries such as oil and gas, chemical processing, pharmaceutical, water treatment, and many more. The seals can accommodate different shaft sizes, pressures, and temperatures, making them compatible with a wide range of operating conditions.

Additionally, metal bellows seals are available in various configurations, including single, double, or tandem arrangements, allowing their implementation in different sealing environments. Their flexibility and resistance to different media enable their effective use across industries, providing reliable and efficient sealing solutions for almost any application. The ability to cater to diverse requirements makes metal bellows seals a preferred choice among engineers and maintenance professionals.

Cost-Effective Solution

While metal bellows seals may have a higher initial cost compared to other sealing options, their long-term benefits make them a cost-effective solution. The enhanced durability and reliability of metal bellows seals result in reduced maintenance and equipment downtime. The reduced need for frequent replacement or repair minimizes overall operational costs and improves productivity.

Moreover, metal bellows seals require minimal flushing or lubrication, leading to additional cost savings. The low friction design and the absence of dynamic elastomers eliminate the need for external lubrication, resulting in lower operational expenses. The extended lifespan of metal bellows seals and their efficient performance contribute to substantial savings over the life cycle of the equipment.

Summary

Metal bellows seals offer numerous advantages that make them an excellent choice for industrial applications. With their flexibility, durability, superior sealing performance, resistance to contaminants, wide range of applications, and cost-effectiveness, metal bellows seals have proven to be a reliable sealing solution across industries. By incorporating metal bellows seals, companies can enhance equipment reliability, reduce maintenance costs, and improve overall productivity. As industries continue to evolve, the use of metal bellows seals is expected to increase, meeting the demanding requirements of modern industrial applications.