Lepu Seal - A Professional China Mechanical Seal Manufacturer providing Cartridge Seal, Grundfos Mechanical Seal And We offer free sample!

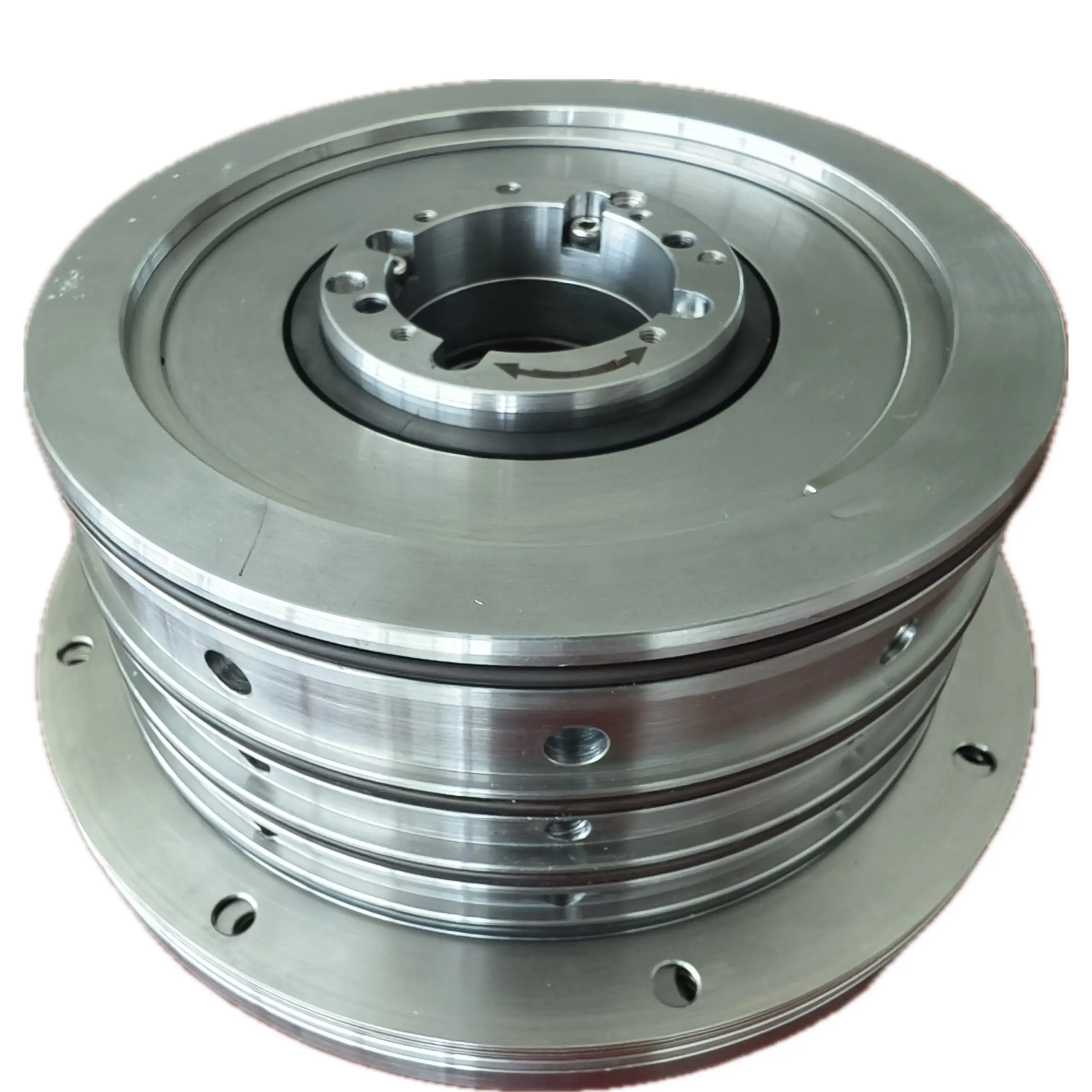

Dry Gas Seal DGS-919571

Dry gas seals are primarily used in centrifugal compressors, turbomachinery, and rotating equipment to prevent gas leaks. They utilize a thin layer of gas (typically the same as the compressed medium) to create a hermetic seal between rotating and stationary components. This non-contact seal minimizes wear and reduces the risk of leakage, thereby improving the efficiency and reliability of the compression process.

Lepu Seal's DGS 919571 dry gas seal is designed for cryogenic applications, particularly excelling in handling liquid industrial gases. Its innovative metal bellows design eliminates the need for dynamic O-rings, ensuring safety, reliability, and best-in-class performance in cryogenic environments.

Whether protecting pumps, compressors, or other cryogenic equipment, the DGS 919571 exceeds industry standards in the following areas:

● Efficiency: Reduces power loss through non-contact sealing surfaces.

● Longevity: Minimizes wear and extends service life.

● Safety: Complies with liquid oxygen (LOX) safety standards.

Product Introduction

The LP Series tandem dry gas seal is a high-performance sealing solution engineered specifically for centrifugal compressors in critical applications. Designed as a reliable alternative to Flowserve dry gas seal systems, it incorporates a robust tandem configuration with redundant sealing layers to ensure maximum safety and operational continuity in gas processing, petrochemical, and high-pressure gas transmission services.

• Can serve as direct replacement for Flowserve GASPAC and other leading dry gas seals

• Non-contacting technology ensures low power consumption and minimal wear

• Compatible with various seal gas conditions and operating pressures

Essential details Of Dry Gas Seal

| MODEL NUMBER | DGS 919571 |

|

SHAFT SIZE |

38-100mm |

|

DISCHARGE TEMPERATURE |

164.1°F |

|

SETTLE OUT TEMPERATURE |

300.0°F |

|

SUCTION PRESSURE |

267.3 PSIA |

|

DISCHARGE PRESSURE |

374.8 PSIA |

|

SETTLE OUT PRESSURE |

65.3 PSIA |

|

PROCESS PRESSURE |

330.1 PSIA |

|

RPM NORMAL |

31867 |

|

RPM OVERSPEED |

46757 |

Why You Need Dry Gas Seals For Compressor Applications?

The problem with an ordinary contacting mechanical seal or “wet” seal is the risk of seal faces overheating at high speed, especially if high speed is combined with high pressure. A common 6500 rpm 70 bar application would be very tough for a wet seal to handle. At such high pv factors, a mechanical seal must have bigger allowed leakage of Plan 54 barrier fluid to prevent overheating and failure. The normally leaking oil is directed back to the oil tank, but not all of it may be collected. Some quantity of the barrier fluid will get into the process (through compressor and into the pipeline), contaminating the transferred gas. In some applications it is “just” loss of oil, easily 1-3 barrels per day. In other industries, contamination with oil involves other cost, for example, contamination of catalyst by a hydrogen recycle compressor at an oil refinery would be to expensive.

In contrast to "wet" mechanical seals, dry gas seals have no contact between the sealing faces. These seals are known as non-contacting, dry-running face seals and are primarily used in high-speed applications. These components include a stationary seal, a rotating seal, and an environmental control system. The stationary seal is typically mounted on the housing, while the rotating seal is mounted on the shaft. The environmental control system regulates the seal's internal environment and is crucial for preventing gas contamination or leakage, meeting the high standards set by API 617.

Dry gas mechanical seals rely on a thin gas film to operate, forming a barrier that prevents any gas from escaping to the external environment. This design not only ensures high efficiency but also minimizes the risk of contamination or leakage, a common problem in the dry gas mechanical seal industry for high-pressure applications.

Unique Features:

● Compact and Easy to Install: Designed for minimal axial and radial space.

● Non-contacting sealing faces: Ensures friction-free sealing faces, extending durability.

● Robust metal bellows design: Prevents shaft/sleeve wear and accommodates high speeds.

● Minimal parts: Simplifies installation and reduces downtime.

● Security standards: Complies with LOX security protocol.

DRY GAS SEAL TESTING

See Lepu's dry gas seals pushed to the limit in our state-of-the-art test lab. This video showcases our rigorous validation process:

Dry Gas Seal DGS 919571 Design:

1. Patented bidirectional groove design

2. Patented rotary seat centering

3. Liquid-phase sintered silicon carbide

4. Internal theoretical gas film modeling

5. Single DGS - for restrictive applications

6. Double DGS - for low-pressure applications where zero emissions are essential

7. Tandem DGS - when lower emissions and a high-pressure solution are required (optional, no intermediate labyrinth)

8. Carbon ring split seal - for protecting the dry gas seal from bearing oil intrusion

9. Carbon ring process seal - for minimizing clean gas flow and maintaining a clean process-side environment

Lepu Seal: A reliable and cost-effective dry gas sealing solution for centrifugal compressors

Our innovative sealing solution eliminates the need for a seal gas booster, protecting the dry gas seal from contamination and reducing maintenance and downtime costs.

The seal protector, located between the dry gas seal and the process-side seal, remains open during operation to prevent contamination. During static or low-speed conditions, it ensures that only clean, dry process gas reaches the dry gas seal.

Benefits of the Lepu Dry Gas Seals solution include:

● Improved reliability: Our simplified design reduces the risk of component failure.

● Reduced costs: Operating and maintenance costs are reduced.

● Minimized footprint: Our system can replace a seal gas booster, saving space.

● Lower emissions: Seal Protect uses less electricity, resulting in lower emissions.

● Seal Protect is compatible with most new compressor trains and can be retrofitted into existing installations to improve reliability.

WHO IS LEPU SEAL FACTORY?

Guangzhou Lepu machinery CO., LTD becomes one of the leading mechanical seal supplier in south of China, we focus in designing and manufacturing mechanical seal for many kinds of famous brand pumps, our mechanical seal cover many kinds of industry like food, petrol chemical, paper making, sea ship, and so on.

Guangzhou Lepu Machinery Co., Ltd.

Add:

No. 5, Yunkai Road, Huangpu District, Guangzhou, China

Tel:

+86-020-36158139

+86-020-36158280

E-mail:

mark@lepuseal.com

Fax: +86-020-36158281

Contact Person: Mr. Mark Ao

Whatapps: +86-18903009893