Lepu Seal - A Professional China Mechanical Seal Manufacturer providing Cartridge Seal, Grundfos Mechanical Seal And We offer free sample!

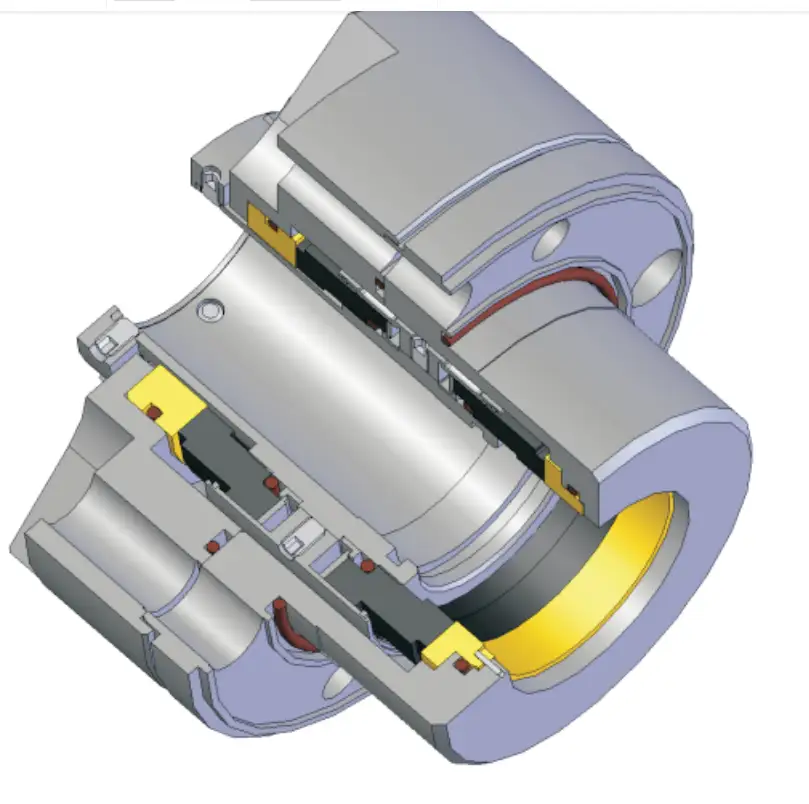

Dry Gas Seal For Chemical Industry Pump LPDGS21

- The dry gas seal consists of a rotating ring and a stationary ring.

- The outer diameter of the rotating ring is machined with micron-scale dynamic pressure grooves (typically spiral grooves, approximately 2.5–10µm deep).

- As the pump shaft rotates, the dynamic pressure grooves pump high-pressure isolation gas (usually nitrogen) supplied from an external source into the gap between the seal faces.

- The gas creates a pressure gradient within the grooves, gradually decreasing from the outer diameter to the inner diameter, generating an opening force.

- When the opening force exceeds the closing force of the seal ring (provided by the spring and the medium pressure), the sealing faces are separated by a gas film, creating a gap of 1–3µm.

- This non-contact seal operates without wear, lubrication, or leakage.

Main Features for Pump Dry Gas Seal:

- It is composed of two sets of single-ed dry gas seals. The principle of "gas blocking" is used instead of "liquid blocking", and the medium is sealed with a sealing gas with a pressure higher than the sealing cavity pressure of 0.2 ~ 0.3Mpa to ensure that the process medium achieves zero environment Escape, meet VOC emission requirements, safety and environmental protection.

- A small amount of sealing gas has entered the process. The seal has high requirements on the pressure of the sealed air source. It must be higher than the pump cavity pressure at any time without interruption.

- The seal adopts cartridge type, convenient installation and disassembly, non-contact operation, energy saving, safety and environmental protection, reliable performance, simple operation, and an average service life of up to 3 years.

- Double seal design, and back to back, fit for long shaft chemical pump.

Working Specifications:

- Pressure: 0 ~ 4MPa

- Temperature: -104 ~ 260 ℃

- Speed: ≤3600r / min

- Applicable working conditions:

- Suitable for various fluid media, mainly used for toxic and harmful, high temperature, easy coking, easy self-aggregation, strong corrosion, granular media, etc. Such as H2S fluid media, solvents, benzene, quench oil, tar, methanol, etc.

Benefit of dry gas seal for pump:

The dry gas sealwas simple, This technology is usually not used in liquid-pump applications, but it seemed to be a good solution because the ethane liquid wants to be a gas.

Dry gas seals delivered enhanced reliability in operating modes where the seal faces are in constant contact—turning, ratcheting, coast-down and other operating modes that create critical conditions for standard gas seals. Experience has shown that unexpected operating situations, such as the transient conditions the end user was experiencing, can compromise a gas seal.

Because seal faces are designed primarily for non-contact operation, they are subject to wear when there is contact for sustained periods. This can cause seal failure resulting in downtime and production loss.

This technology also provided simplification of the sealing system. In this application, the liquid ethane is very clean. It is typical to filter the ethane prior to injecting it back in the seal area; otherwise, there is a risk of damage to the dry gas seal faces. A filter flush can increase the stuffing box pressure, which increases the vapor margin and makes it more difficult to vaporize the liquid.

Instead of using a flush, if some particles were in the liquid, the special bonding would either crush them, or if they are small enough, the special dry gas seal groove pattern would pass them along. No filters were needed, which reduced maintenance costs and downtime.

Why buy dry gas seal from LEPUSEAL?

Dry gas seal manufacturers provide contactless sealing solutions for rotating shafts in high-speed equipment. The dry gas seal working principle involves injecting clean and dry air or inert gases into a precise clearance between the shaft and seal housing, forming a stable gas film that serves as a non-contact barrier against external environment. Without liquid or additional magnets, our dry gas seals feature simple and compact structure, adaptive sealing, and frictionless operation. The non-contact gas film eliminates wear and leakage issues associated with mechanical seals, showcasing the difference between dry gas seals and mechanical seals in performance and longevity. Cooling effect and long service life are also achieved.

Our dry gas seals are customizable with multiple tandem seal stages for enhanced sealing performance. There are various dry gas seal types available, along with different dimensions and mounting configurations to fit diverse equipment needs in aerospace, oil and gas, food and pharmaceutical, electronic and semiconductor industries. Providing reliable, maintenance-free and environmentally clean sealing, our dry gas seals are ideal solutions for high-speed rotating machinery. The dry gas seal installation process is straightforward, minimizing downtime. Understanding the dry gas seal components is crucial for maintenance, enhancing the appeal of our products. Contact us today to find the optimal sealing for your application!

Lepu seal focus one mechanical seal since 1998, making mechanical seal include dry gas seal for many clients from different countries, more than 100 countries user had used mechanical seal from lepuseal, and offer positive feedback.

if compared the world famous brand for dry gas seal, like ealgeburgmann, john crane, aesseal, flowserve and so on. lepuseal can offer similar quality, but with cheaper price, and faster delivery. those are the main reason more and more users buy dry gas seal from China LEPUSEAL.

Why are More and More Centrifugal Compressors Using Dry Gas Seal Technology?

Many compressors today are older than their predecessors, potentially preventing them from meeting the latest performance and environmental standards. Retrofitting these older units with the latest dry gas seal technology can improve operational performance, including reliability, service life, and productivity. Over 85% of centrifugal gas compressors manufactured today are equipped with dry gas seals. Because dry gas seals can also reduce a plant's environmental footprint while significantly reducing emissions.

Natural Gas STAR company have found that replacing these "wet" seals with dry seals significantly reduces operating costs and methane emissions.

Methane emissions from wet seals typically range from 40 to 200 standard cubic feet per minute (scfm). Dry seals, which use high-pressure gas to seal the compressor, emit less methane (up to 6 scfm), have lower power requirements, improve compressor and pipeline operating efficiency and performance, enhance compressor reliability, and require significantly less maintenance. A dry seal can save about $135,000 per year and pay for itself in as little as 14 months. For example, reduced emissions by

PRODUCT TECHNICAL SPECIFICATION

Mission-critical operators trust LEPU Seal's dry gas seals to reduce emissions. Get a quote now and join the growing number of customers who are improving sustainability and reliability with our dry gas seal retrofits.

Ressure: 0 ~ 4MPa

Temperature: -104 ~ 260 ℃

Speed: ≤3600r / min

Guangzhou Lepu Machinery Co., Ltd.

Add:

No. 5, Yunkai Road, Huangpu District, Guangzhou, China

Tel:

+86-020-36158139

+86-020-36158280

E-mail:

mark@lepuseal.com

Fax: +86-020-36158281

Contact Person: Mr. Mark Ao

Whatapps: +86-18903009893