Lepu Seal - A Professional China Mechanical Seal Manufacturer providing Cartridge Seal, Grundfos Mechanical Seal And We offer free sample!

Profesional Mechanical Seal For Oil Industry SEE-100

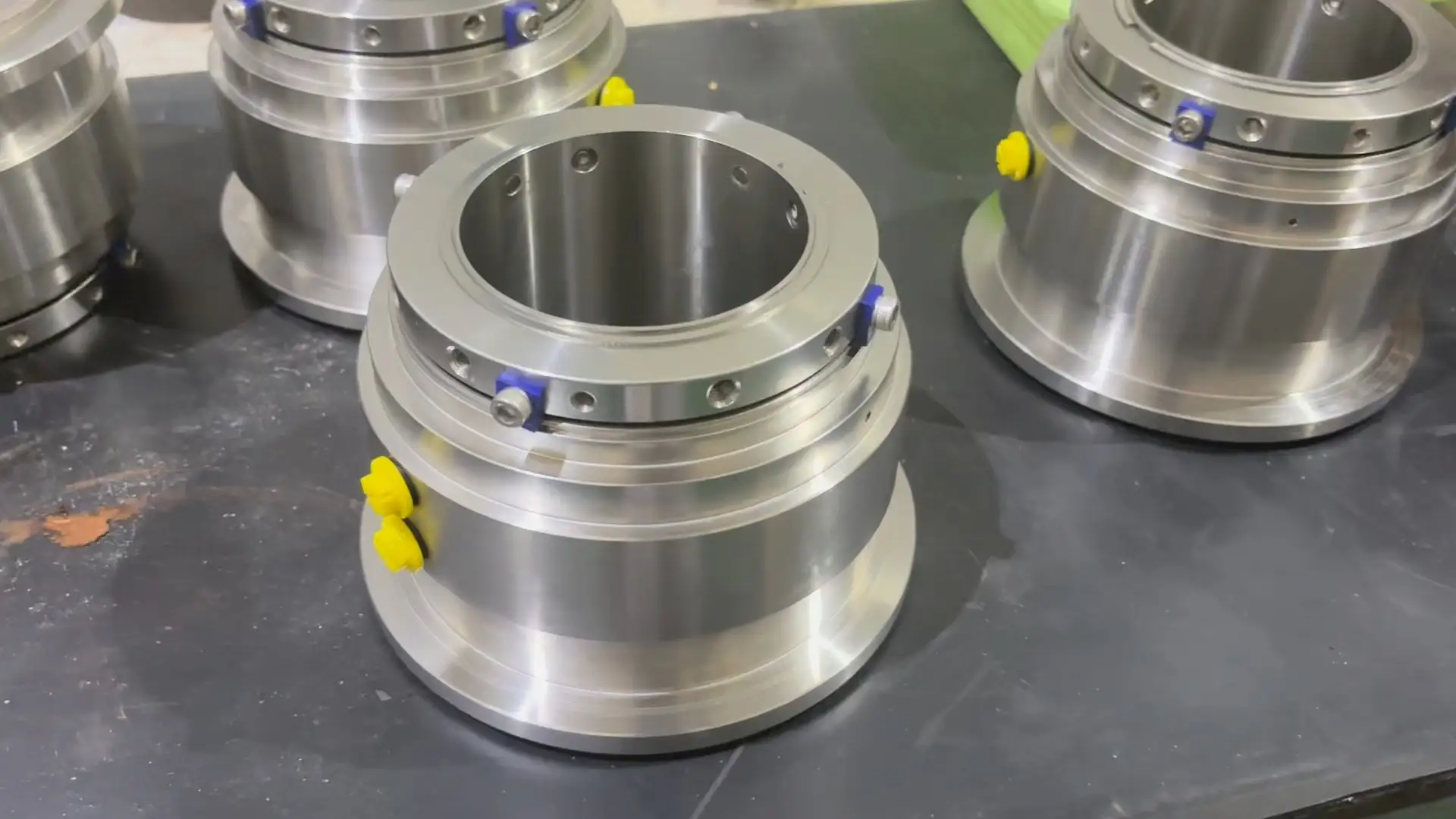

Mechanical Seal SEE-100

The SEEPEX pump seal replacement market demands precision-engineered solutions, and the SEE-100 delivers exceptional performance for progressive cavity pumps across critical industries. Designed as a direct substitute for original SEEPEX mechanical seal components, this advanced sealing system addresses the rigorous requirements of hydrocarbon processing, chemical transfer, and viscous fluid handling. Its core innovation lies in specialized materials and geometry that mirror OEM specifications while enhancing durability in abrasive and high-temperature environments commonly encountered in petrochemical applications.

As a dedicated SEEPEX seal for oil industry operations, the SEE-100 incorporates silicon carbide primary sealing faces resistant to sour crude contaminants and paraffin buildup. The balanced design manages shaft deflection and axial movement inherent in SEEPEX pump mechanics, preventing premature failure during heavy-duty cycles. Proprietary elastomer formulations combat swelling and degradation when exposed to aromatic hydrocarbons, biodiesel blends, and well injection fluids – making it ideal for upstream extraction, midstream transportation, and refinery operations where seal integrity prevents costly environmental incidents.

● Lepu Seal mechanical seal manufacturer & supplier can provide OEM service.

● We are a mechanical seal manufacturer with 25 years of production experience since 1998 in China.

Mechanical Seal SEE-100

This mechanical seal for petro-chemical industry applications excels in handling aggressive media including chlorinated solvents, acid catalysts, and polymer slurries. Its modular construction allows quick field replacement without pump disassembly, featuring laser-etched rotational direction markers to prevent installation errors. The anti-clogging groove technology actively expels particulates in processes like bitumen transfer or waste oil reprocessing, maintaining consistent sealing pressure even with fluctuating viscosity and solid content.

Third-party validated in offshore platforms and chemical plants globally, the SEE-100 reduces unplanned downtime by 40% compared to conventional seals. Compliant with API 682 Category 1 and ISO 21009 standards, it comes with full material traceability documentation and explosion-proof certifications (ATEX/IECEx). For operations relying on SEEPEX pump technology, this seal redefines lifecycle value through extended mean-time-between-replacement (MTBR) and reduced hazardous fluid containment risks.

Essential details Of Mechanical Seal SEE-100

|

Brand Name |

LEPU Seal |

|

Place of Origin |

China |

|

Model Number |

SEE-100 |

|

Shaft Size |

100mm |

|

Metal Parts |

Stainless Steel |

|

Working Temperature |

-40℃-- +180℃ |

|

Working Pressure |

≤ 1.5 Mpa |

|

Liner Speed |

≤ 20 m/s |

|

Avaiable Material |

CAR/SIC/VITON/SS316/SS304/NBR/EPDM/TC |

|

Standard or Nonstandard |

Standard |

WHO IS LEPU SEAL FACTORY?

Guangzhou Lepu machinery CO., LTD becomes one of the leading mechanical seal supplier in south of China, we focus in designing and manufacturing mechanical seal for many kinds of famous brand pumps, our mechanical seal cover many kinds of industry like food, petrol chemical, paper making, sea ship, and so on.

Guangzhou Lepu Machinery Co., Ltd.

Add:

No. 5, Yunkai Road, Huangpu District, Guangzhou, China

Tel:

+86-020-36158139

+86-020-36158280

E-mail:

mark@lepuseal.com

Fax: +86-020-36158281

Contact Person: Mr. Mark Ao

Whatapps: +86-18903009893