Lepu Seal - A Professional China Mechanical Seal Manufacturer providing Cartridge Seal, Grundfos Mechanical Seal And We offer free sample!

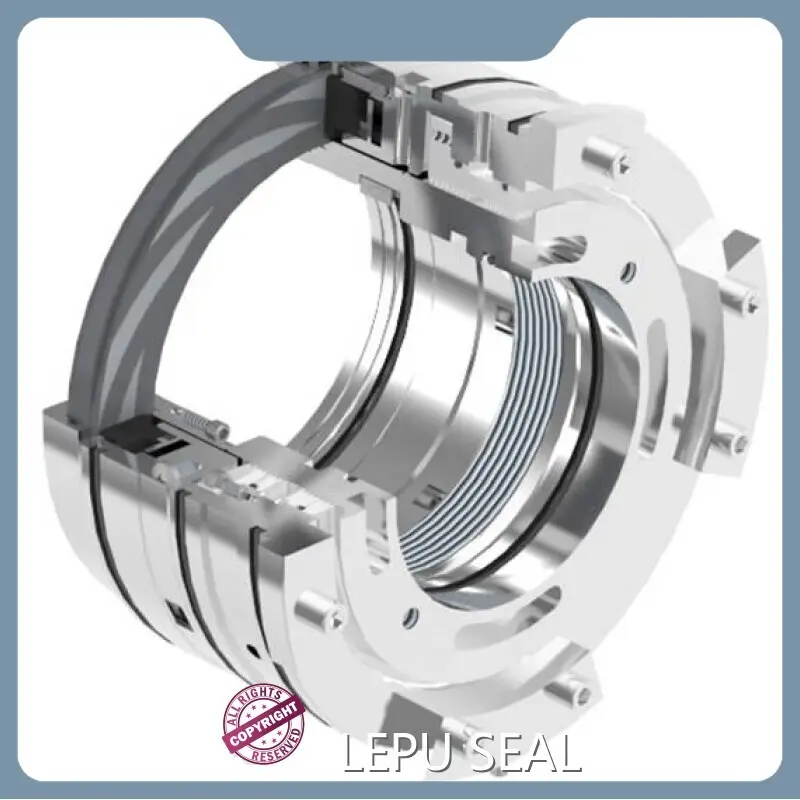

Industrialflowserve Dry Gas Seal for Petrochemical Industries 100-300mm 60-90days

Product Overview

The Industrial flowserve Dry Gas Seal is designed to seal the rotating assembly in stationary compressor cases to prevent process gas from escaping into the atmosphere and vice versa in centrifugal compressors.

Product Features

The LPDGS-801 dry gas mechanical seal is specifically designed for centrifugal compressors, with a primary and secondary seal system for added safety and reliability. It is injected with buffer gas under pressure to improve lubrication and extend the seal's service life.

Product Value

This dry gas seal offers improved reliability, reduced maintenance costs, increased safety, better performance, and environmental protection. It is suitable for toxic and hazardous, flammable and explosive fluid media in petrochemical industries.

Product Advantages

The advantages of dry gas seals include improved reliability, reduced maintenance costs, increased safety, better performance, and environmental friendliness. These seals have fewer parts, require less maintenance, and eliminate the risk of seal leakage.

Application Scenarios

The LPDGS-801 dry gas seal is suitable for centrifugal compressors handling ethylene, propylene, liquefied gas, ammonia, MTBE, butadiene, aromatics, benzene media, and more. It is widely used in petrochemical industries for sealing high-pressure natural gases and preventing environmental damage.

Guangzhou Lepu Machinery Co., Ltd.

Add:

No. 5, Yunkai Road, Huangpu District, Guangzhou, China

Tel:

+86-020-36158139

+86-020-36158280

E-mail:

mark@lepuseal.com

Fax: +86-020-36158281

Contact Person: Mr. Mark Ao

Whatapps: +86-18903009893